By Steven Sullivan and Chris Iannello

Good systems engineers can handle technical leadership and systems management.

Students fill a balloon for the team’s project test flight with the Rocket University payload launch and recovery lab.

Photo courtesy of Steven Sullivan and Chris Iannello

Both skills are critical when developing and operating any space-related system. We developed RU’s curriculum around this idea and built it using a combination of vendor-purchased training and civil-servant-developed courses.

An important goal of the RU curriculum is to incorporate the teachings of NASA’s well-respected APPEL (Academy of Program/Project and Engineering Leadership) training into its program. By incorporating a technical curriculum to compliment the APPEL program, RU focuses on teaching systems engineering of the integrated project as well as within each discipline. RU students take classes that combine APPEL’s broad systems engineering training with technical training in unfamiliar disciplines. Once trained, the students are challenged to use their new skills as part of a project team to conduct a lab flight project or experiment. They must work on this project from its inception to its completion, immediately demonstrating their new skills as they simultaneously apply their systems engineering training throughout a complete project life cycle.

This immediate application of newly learned technical and managerial skills is what makes RU different from other training programs.

Balloon Payload Launch and Recovery Lab

In October 2011, RU began offering weather-balloon courses as part of its near-space environments lab curriculum. These classes were meant to introduce Kennedy engineers to the benefits of using balloons to achieve inexpensive and long-term science and technology objectives. The labs include a series of iterative challenges to be achieved during four incremental test flights.

According to one RU mentor, Nicole Dawkins, “Participants of Rocket University’s near-space environments team are developing expertise in everything from composite manufacturing to the latest in avionic and software design techniques. The added bonus is that the engineers are learning these skills as they build and fly real products that impact future NASA programs.”

For test flights, Johnson Space Center is the principal investigator. The students’ main flight objective is to provide Johnson with test-flight data that will help them create the final design for an unmanned capsule that can be deployed from the International Space Station to Earth.

The first balloon-lab test flight has been completed. For this flight, RU students designed and built an instrumented payload, launched and tracked a balloon from the Kennedy Visitor’s Center, and tracked a dummy payload receiver using a global-positioning system (GPS). The balloon reached 95,000 ft., but the payload landed 45 miles offshore and was not retrieved. This balloon flight was the first step in incremental development, where RU coursework and projects evolve into the avionics that will support our aeroshell drop-test customers as well as all other RU flight objectives. The lessons learned from this first lab will also be used to improve the second balloon-flight test, which will feature additional challenges, such as using a flight computer, providing two-way telemetry that handles commands and responses, establishing a flight-termination system, providing data-recording capabilities, and predicting the balloon’s landing location within 1 mile.

“Every time the near-space environments team successfully launches a balloon payload, we are demonstrating new skills and techniques learned within the curriculum of Rocket University,” explained Dawkins. “There is a lot of satisfaction in knowing that we designed, built, tested, and flew a product that will impact future NASA programs.”

Lessons learned from the second test flight will be used to plan and conduct the third flight, which will include deploying a small (7- to 8-lb.) capsule that will land in the ocean. This aeroshell-scale drop test will require new design efforts such as creating the small-scale test capsule and designing the landing parachute. Performing this small-scale model drop test will help the Johnson design team catch failures early as the data generated during the test will be used to design a larger, 200-lb. aeroshell capsule. This larger capsule will eventually fly on a stadium-sized balloon in Fort Sumner, N.M., and is being offered by the Wallops Balloon Program Office and the NASA Columbia Scientific Balloon Facility in Palestine, Tex. The capsule will be dropped at around 120,000 ft. to collect data that can be used by Johnson to design their final product.

Focusing on the Individual

RU’s “technical discipline leads” teach a variety of classes. In several cases, the technical discipline training classes were conducted in collaboration with experts from other NASA centers who developed coursework and taught the classes. The curriculum also covers major technical discipline areas:

- Systems engineering (provided through APPEL training)

- Flight structures

- Avionics/embedded systems

- Propulsion (liquid and solid rocket)

Once students complete their technical discipline classwork, they apply their newly gained knowledge and can test their proficiency on a lab project or experiment. The final exam for the lab is the flight project itself.

RU currently has four main lab/experiment project types:

- Near-space environments

- Unmanned aerial systems

- Rocketry (transonic and hypersonic)

- Propulsion system test beds

The RU team shows the Kennedy Space Center Engineering director the analysis associated with the team’s first certification build.

Photo courtesy of Steven Sullivan and Chris Iannello

To date, these labs have resulted in more than a dozen rocket launches and two balloon launches, each of which involved incrementally designing custom flight hardware and software.

RU labs operate with a large number of project teams, but each team is fairly small and given very small budgets. Limited manpower and a low budget: these realities set the stage for team labs.

The NASA model rarely leaves one person solely responsible for building a critical subsystem, but this is not the case at RU where, because of limited manpower, one engineer can sometimes be assigned to work within an entire system. This means a lot of hands-on engineering that provides lessons and insights that can’t be gained in any other way. Thomas Edison said, “Opportunity is missed by most people because it is dressed in overalls and looks a lot like work.” At RU, our labs provide each student with lots of “overalls” moments and opportunities for personal and team successes.

Students work with a principal investigator to set project objectives as well as with mentors, who support them throughout the project. As students begin their work, they become believers in applying agency guidelines for program management because they quickly learn that organization can solve a lot of frustrations between systems engineers. They also soon realize that agency collaboration is required to help find technical solutions from experts across NASA and across different disciplines. Finally, the project team must report to all levels of management (that is, engineering director, chief, division/branch chiefs), who actively participate in major project reviews. Given the limited manpower assigned to each project team, the entire process stresses responsibility and leadership on the part of each individual.

In addition, small budgets often force team members to build, by themselves, the functions or systems they require to complete their project (for instance, data-logging telemetry downlinks or inertial navigation systems). Doing this work gives team members a deeper understanding of flight functions than they would get if they could simply buy technical solutions. It also forces them to find and use low-cost materials and resources. Many students have become more knowledgeable about how to apply commercially available hardware and software to their projects, which opens their minds about using commercial-grade constituent parts as they create custom-built hardware and software designs to meet lab requirements.

Additional Accomplishments

In addition to the success achieved with RU’s near-space balloon launches, several other labs have seen similar accomplishments since RU began in the early fall of 2011.

Avionics

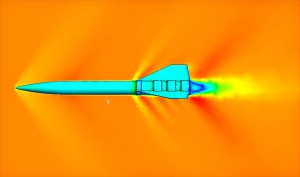

Computational fluid dynamics analysis for the Rocket University advanced rockets workshop. The second stage was analyzed at Mach 1.4 to determine the aerodynamic performance of the rocket at its maximum expected velocity. The colors in the image correspond to velocity of the air, with multiple minor shockwaves seen emanating from the rocket as it flies supersonic.

Photo courtesy of Steven Sullivan and Chris Iannello

The RU avionics discipline supported the balloon lab’s first untethered launch by designing a custom avionics system that used the latest in mixed-signal embedded electronics. This system is much more capable than similar systems available either commercially or within academia. Amazingly, the hardware cost of the system was under $350, with the majority of the expense going toward purchasing the downlink transceiver and the Ublox GPS with integrated antenna. The system consists of a 32bit microchip PIC with 512 KB of flash RAM and, stretching outward from the microcontroller, high-speed synchronous and asynchronous serial busses that connect sensors as well as radiofrequency links. The low-cost, high-performance embedded electronics used in this flight served to further develop RU’s technical skills in that we learned to use nontraditional hardware types. This avionics package is in its first revision and will be improved upon by RU avionics students with each balloon-lab test flight.

Transonic Rocketry

During the introductory class on basic rocketry, students learned about center-of-pressure calculations, center of gravity, available models and simulations, and their accuracy. In the lab, students handcrafted their own high-powered rockets and flew them with rocket-enthusiast clubs sanctioned by the Federal Aviation Administration. From these launches, students learned lessons regarding the performance of off-the-shelf accelerometer data-collection devices; the benefits of live video and sound streams to examine the environments, rate, and violence rockets are exposed to; and parachute deployments that resulted in either reparable rocket damage upon landing or no recovery due to high-wind conditions. The class was a great start for future transonic-rocketry studies.

Unmanned Aerial Systems (UAS)

A series of training sessions provided students with an introduction to UAS: practices and principles; flight dynamics; modeling and simulation; guidance, navigation, and control; communication systems; composite-material manufacturing complete with a familiarization of Kennedy’s prototype shop; and systems engineering and integration workshops. These courses were taught through a collaborative effort between NASA and Embry-Riddle Aeronautical University (ERAU). The extremely challenging lab project for UAS students involves designing, manufacturing, and testing a viable UAS. The project anticipates flight testing to begin in summer 2012, culminating in a planned autonomous UAS mission.

Educational Outreach

As RU progresses, it seems natural that the university and its curriculum could also be used to foster outreach opportunities between NASA and public/private engineering institutions. Since all RU classes are videotaped, they can easily be offered to outside universities; and because of the low cost of lab materials, the program is affordable to implement. Already the University of Central Florida and ERAU have sent faculty to teach at RU. These institutions are also providing students to work as special teams to assist NASA engineers during design, manufacturing, and testing procedures.

Hands-on opportunities and working side by side with NASA engineers help make these students workforce-ready. As RU’s educational outreach expands, it could also be disseminated to high-school or middle-school levels to support national science, technology, engineering, and math initiatives. The collaborative possibilities between educational institutions and government agencies will continue to grow.

What Lies Ahead

Rocket University continues to expand its curriculum, finalize “graduation” requirements, further identify opportunities to collaborate with educational institutions, and work toward creating an exciting agencywide technical challenge. This challenge would be offered to all NASA centers and would culminate in a competitive, yet collaborative, effort among the centers. Each team would congregate at one NASA location to present their concept and design, conduct a demonstration to show how their design satisfies challenge requirements, and, finally, discuss their results and lessons learned.

RU interested? If so, please contact the Rocket University program manager, Kathleen O’Brady, at 321-861-3300 for more information.

About the Authors

|

Chris Iannello began his career at Kennedy Space Center in 1989 in the ground power systems group and has more than twenty years experience in power systems. He has been involved in some of manned spaceflights most challenging technical issues, and he has served or led on assessments for the NASA Engineering and Safety Center. As a researcher, he has published over twenty papers in engineering journals, leading discipline conferences, and tutorial seminars. |

|

Steven Sullivan is the chief engineer of NASA’s Commercial Crew Program at Kennedy Space Center. He began his NASA career in 1985 as a shuttle engineer and served in various roles within the Space Shuttle program, including branch chief and later division chief for electrical systems and chief engineer of launch-vehicle processing in Kennedy’s Engineering Directorate. He also led resolution of engineering issues related to processing and launching shuttles Discovery, Atlantis, and Endeavour. |