ASK OCE — May 10, 2006 — Vol. 1, Issue 8

When Johnson Space Center’s Kim Ess took the reins of the Space Shuttle’s Orbiter Boom Sensor project in the wake of the Columbia disaster, she was told she had less than a year to develop a system that was absolutely critical to the Shuttle’s return to flight.

The Orbiter Boom Sensor System (OBSS) that her team had to design was a 50-foot boom that would inspect the shuttle for external damage that could jeopardize it during re-entry, as happened with Columbia. Its instrumentation package would consist of visual imaging sensors that could achieve resolution of few millimeters and scan at a rate of about 6.35 centimeters per second. The OBSS would inspect the leading edges of the wings, the nose cap, and the crew compartment after lift-off. If flight engineers suspected potential damage to other areas, then additional regions could also be scanned.

In addition to the tight deadlines, Ess faced a host of new project management challenges. As a Shuttle system, the OBSS was considered a Return to Flight project, which meant it was subject to new requirements that were put in place immediately following Columbia.

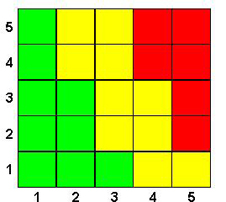

One of these requirements was to present a risk management matrix, first on a weekly and then monthly basis. The matrix, known as a “5×5” because of the size of its grid, provides a snapshot of a project’s risk profile in terms of likelihood and consequences.

As an experienced project manager, Ess was no stranger to risk management, but she had not used the 5×5 format in her previous work. With the demanding schedule of the OBSS, it struck her as a cumbersome bureaucratic requirement that would eat up precious time. “I didn’t like it at first,” she said. “It was just one more product to turn out.”

At her weekly presentations to management, however, she began to notice that it had a value she hadn’t anticipated. “I would have it as my first or second slide and say, ‘Here’s the risk I’m talking about today.'”

She found that using the matrix preempted any “surprises” about the risks her project faced. “That was the biggest help. Other people at NASA knew what to expect even before I spoke.” Her own thoughts about the 5×5 changed as she saw it as a useful tool for risk communication; it became a useful springboard for discussing technical problems. In all the cases where such problems occurred, the risks, consequences, and associated mitigations had already been identified. “I even began to like it,” Ess said.

In This Issue

Message from the Chief Engineer

NASA on the Hill: Administrator Griffin Testifies about Budget

This Week in NASA History: Magellan Heads to Venus

PM Challenge 2006 Draws 1,000

GAO: NPOESS Requires Agency Attention

Risk Communication: One PM’s Perspective

Leadership Corner: A Speech is Not a Data Dump

It’s a Small, Small World: NASA Nanotechnology

Archimedes Archive: The First Flight of Traian Vuia