By Jose Lopez

The challenge is twofold. First, as with any aging structure, much of the piping, HVAC, fire-protection, electrical, communications, and other systems are outdated or beyond their intended lifespan.

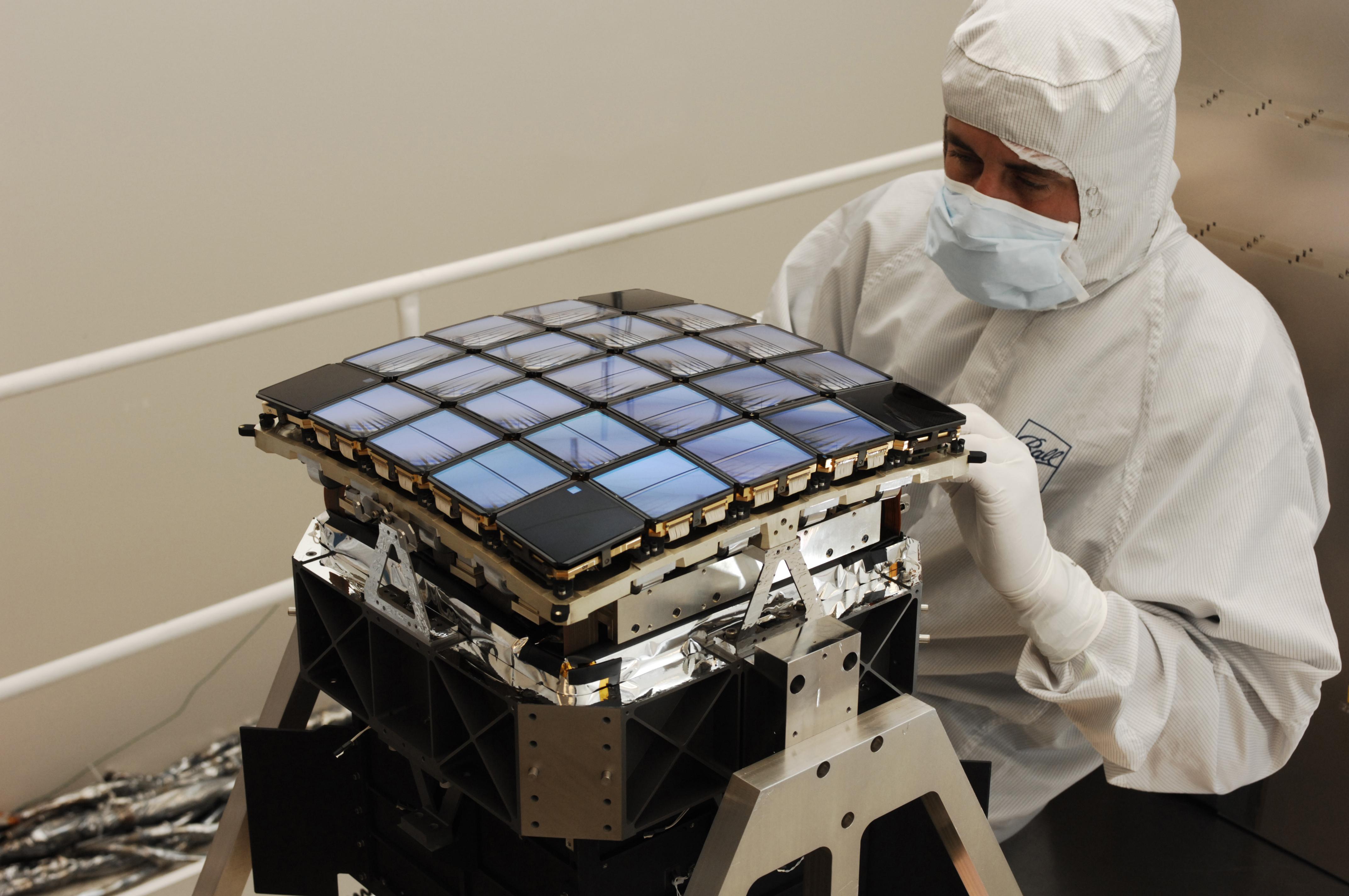

A floor-level look at the huge Apollo- and shuttle-era platforms that will be removed from high bay 3 of the VAB.

Photo Credit: NASA

In addition, the improvements must take into consideration the servicing of more than just one launch-vehicle configuration.

The existing VAB access platforms used in previous programs are not able to be reused and must be demolished to make way for new platforms and infrastructure that can accommodate more than one launch vehicle. The challenge is to design and construct systems that are relocatable and able to access critical areas of multiple launch-vehicle configurations. It affects not only work platforms for personnel access, but also access for commodities such as power, communications, nitrogen, helium, compressed air, and other gasses. Given the variety of vehicles that will be serviced in the VAB in the future, including some that have not yet been designed, it was essential that the new access system be moveable and adjustable. In order to advance the concept of relocatable platforms, the VAB team consulted with operations and safety experts to understand the steps and duration involved with reconfiguring a high bay. We also coordinated with commercial and industrial entities to brainstorm various concepts to move massive steel structures with greater precision.

To arrive at our selected concepts for the overall VAB infrastructure, we developed an extensive partnering process between our project management team, the vehicle-processing operations, facilities operations, and safety communities. We know very well that without the collective buy-in of the larger NASA organization, we would not be assured of the success of our vision.

Much of the VAB’s current infrastructure, which is more than four decades old, is also in need of refurbishment. This massive building is as old as I am, and even I can admit to needing an occasional visit to a doctor, so why shouldn’t the VAB?

The first major renovation project consists of demolishing the seven access platforms in high bay 3 and replacing them with new platforms. The entire system will be vertically relocatable and able to translate horizontally to accommodate access points on different launch vehicles. Each platform of the new design will also be equipped with its own lighting, fire sprinklers, and interface panels for commodities. Other systems in the VAB structure, such as elevator landings and emergency egress paths, are also affected and must be considered in the overall operational design of the facility.

The refurbishment of the VAB will include removing seven Apollo-era platforms from high bay 3 and replacing them with modern versions that can be relocated and reconfigured for multiple launch vehicles.

Photo Credit: NASA

With the advances in communications technology, much of the existing communications cabling in the VAB is now abandoned or antiquated. One project consists of removing about 150 miles of old lead and copper cables and replacing them with a state-of-the-art fiber-optic communications backbone. The backbone will provide the communications infrastructure needed to support multiple users during vehicle processing.

The mechanisms that move the 45-story high-bay doors are being refurbished. Each of the four high bays contains a door that consists of two horizontal sliding sections and seven vertical lift leaves. Each door leaf is powered by a separate motor and is suspended on three wire-rope cables. The motors are being fitted with a secondary brake system and the wire ropes that move the doors, a total of 8 miles of cable, are being replaced. Not only will these changes make the doors more reliable, they will also be safer to operate. The mechanisms that operate the doors will have a backup brake system and new electronic controls that will enable smoother emergency braking operations. Other work is also being performed to improve access and lighting to be able to service and maintain the doors more efficiently in the future.

The VAB also houses five primary cranes ranging from 175 to 325 tons in capacity. The 175-ton crane is receiving upgrades to its control systems. Installing advanced technology equipment will allow the cranes to operate more reliably with enhanced precision. This is a must when lifting and assembling critical flight hardware. These improvements require the cranes to be out of service for extended periods of time, making this the ideal time to perform these types of upgrades.

The fire protection and detection system in the VAB is in the process of being upgraded to support processing of future launch vehicles. Much of the fire distribution piping is at the end of its usable life and undersized to facilitate future operations. Additionally, the pumps that provide water to the fire sprinklers are being replaced with upgraded, larger, and more reliable pumps that can be serviced and maintained without affecting operations in the VAB.

Other building infrastructure such as potable water, sanitary sewer, storm-drainage piping, and low-voltage power systems are “original equipment” that was installed when the building was first constructed. After forty-six years, some cast-iron pipe systems have deteriorated, and electrical wiring and equipment have reached the end of their usable life.

The launch vehicles are assembled on mobile launcher platforms that sit on top of a crawler transporter that moves from the VAB to the launchpad. Once the vehicles are stacked, the VAB floor, foundations, and other structural elements must be able to support the weight of the entire system. The previous Apollo and shuttle launch systems weighed about 18 million pounds. The new SLS system will weigh considerably more—on the order of 25 million pounds. Consequently, the floor, foundations, and building threshold, as well as the crawler transporter itself, are undergoing modifications and upgrades to accommodate the additional weight of the new launch system.

A conceptual look at the future of the VAB, with high bay 3 configured for processing the Space Launch System heavy-lift launch-vehicle series.

Image Credit: NASA/Boeing

All in all, it really is building renovation on a grand scale. The end of the shuttle program has provided a window of opportunity for us to perform necessary modifications to the VAB in preparation for future launch-vehicle processing at Kennedy—without the added expense and much greater complexity of doing the work while still processing flight vehicles at the same time. The work will require multiple construction contractors to work within the building confines simultaneously, safely, and efficiently. When it is all done, we will be able to assemble, service, process, and test Americas next generation of launch vehicles. On that day, we take a step back and reflect on the accomplishments that make us proud to be Americans—and say, “We are ready for tomorrow.”

If I were to capture some of the most crucial lessons learned during these critical phases of a project, I would remind anyone in my position to closely listen to the project managers and engineers that came before you, and capitalize on the nuggets of information from the years of excellent mentoring you received. Some of that great knowledge comes from engineers who were involved with the first major modifications to the VAB, between the Apollo and shuttle programs—some of whom are still here.

Over the years, I have worked with many brilliant engineers. Most of them were great for providing “don’t do” lessons from their own experience: “Don’t limit your future load limits on…,” “Don’t underestimate your future power loads on…,” “Don’t forget to provide access to…” Its amazing how much wisdom we gain from our failures and successes.

Remember, we don’t always need to reinvent the wheel—we just need to keep making it better.

About the Author

|

Jose Lopez’s twenty-five-year career at Kennedy Space Center spans the areas of shuttle facilities systems operations and maintenance, facilities electrical-controls design, expendable launch-vehicle operations, base operations contract management, and project integration under the Constellation program. His current role as VAB deputy project manager for the Ground Systems Development and Operations program has been his most challenging and rewarding position in all his years with the administration and the military. |