Glenn Research Center’s Rocket University program is giving Kristen Bury her first shot at working with real flight hardware.

In November 2013, Glenn Research Center launched its pilot Rocket University (“Rocket U”) program. Designed to give early-career Glenn employees hands-on project experience throughout the full lifecycle of a flight project, the program seeks to develop the next-generation workforce as they transition into higher-profile projects. APPEL News caught up with Kristen Bury, a power systems engineer at Glenn and Rocket U team member, to learn more about her background and her experience on the project so far.

APPEL News: Let’s start from the beginning. What was your path to working at NASA?

Kristen Bury: I have wanted to work for NASA since I was a little kid. That was the goal from day one. Everything I did in grade school and high school was all so I could work here.

I went to the University of Toledo in Ohio and got my Bachelor’s degree in Chemical Engineering. Our program had mandatory co-ops that we had to do throughout my degree and so we had career fairs. NASA came to one of them and I remember getting there 30 minutes early–I was at the front of the line. I can remember walking down the hallway past all of these booths of employers. I completely ignored them and went straight to the NASA booth. Thankfully, I was able to get a co-op position. So that’s how I got here—I made a beeline for the NASA table, got an interview, and it went well.

APPEL News: And what is your current role now?

Bury: I have worked in power systems engineering the whole time that I’ve been here. I started in September of 2007 as a co-op and then I was hired on full time in 2010. I have been doing mostly power analysis work for spacecraft and then power system design. I look at solar arrays, batteries, and the wiring that hooks them all together (all of the electronics) and I make sure everything on the vehicle that needs power gets it. I design those components and then I run analyses on them to see if they’re working the way that they’re supposed to, and make sure I understand what’s going on in our power systems.

APPEL News: Is that a natural career progression, to go from chemical engineering to working on power systems?

Bury: (Laughter.) No. I was surprised to be doing electrical engineering when I first came in, but I was just so excited to be here and to be making an impact in our space program, that I dove right in. It was definitely a steep learning curve when I started; some frustration and some feelings of “I’m not going to be able to do this, I’m not smart enough” but after about four years, things started to click. (Laughter.) I got my degree in electrical engineering, so to speak, from “NASA University.” Now, it’s my day job. I live and breathe power systems.

APPEL News: What helped you get acclimated?

Bury: The mentors we have here. We have several senior engineers in our branch who are world experts in their field, so I really was learning from the best. They just did a fantastic job of taking me under their wing and teaching me everything that they could. I am still learning from them every day and I’m just very blessed to have a good group of mentors who are willing to help in my group. They are all just very supportive of the earlier career engineers and helping us learn, and they want us to succeed, which is great.

Of course, that said, I’ve also taken basically every APPEL course that has ever been offered. That has helped, too, to come on board and get a better understanding the agency culture and how we do business at NASA because you kind of need both sides of that—the technical and the cultural—to really be successful here.

APPEL News: Tell us how you became involved with Rocket U? How did you learn about it and why did you want to participate?

Bury: We have an internal news site called “Today at Glenn” and I saw it posted there a little over a year ago. I don’t have any hands-on experience with hardware. All of my work is theoretical; I sit at a computer running simulations or doing design work, and I don’t actually get to see, touch, and feel the things that I design or that I’m analyzing. So the thought of working on real hardware and taking a project from just a twinkle in your eye all the way through to completion where you’re actually going to launch something just sounded fantastic.

One of the challenges at NASA is that sometimes programs can get cancelled before they ever get to completion. I’ve never been through the entire project lifecycle in my career and I really wanted to see that because I’m definitely interested in moving into project management later in my career. I feel like I need to see the full lifecycle of a project in order to be a good project manager. All I know is pre-Phase A (conceptual study) up to preliminary design review (PDR). I’m not much good as a project manager if I never make it past a PDR. The prospect of seeing the whole lifecycle of the project was just really exciting to me.

I also really want to solder something. If I don’t do anything else during this year, I at least want to solder something.

APPEL News: Tell us about the project. Will there be things to solder?

Bury: Oh yes, there will be things to solder, electrical circuit boards, etc. It’s all going to be new to me.

Ultimately, what we want to do is design some sort of a system that will help lessen the impact loads on a balloon gondola when it lands after an experiment. Normally when we do balloon science missions, once the mission is over, the gondola is separated from the balloon and it just falls down to Earth and crashes. So you can’t really reuse anything between balloon flights. Something that would really help more balloon missions be more cost-effective is the ability to reuse some of the equipment after the gondola gets dropped. So that’s a big technical challenge.

APPEL News: How do you plan to address this challenge?

Bury: Have you seen a balloon gondola? They’re very tall. It’s easy for them to fall over or for things to start tumbling around on the ground when they land. It’s not easy to control how they land.

Right now in the project, we’re at a turning point; we’re not quite sure which way our project is going to go. We’re looking at two different solutions for protecting the balloon gondola. One would be a “smart” airbag system, so to speak. Depending on how the vehicle is oriented before it impacts, airbags would deploy on that side of the vehicle to protect it from landing too hard, and, hopefully, it would protect the payload and some of the more sensitive systems on the vehicle.

Our second option is while the vehicle is descending—so after we cut the vehicle off from the balloon—we could use a parasail (“parafoil” is the technical term) and it would allow us to control the descent of the vehicle and have land it in a very specific location. This way we don’t have to worry about the vehicle floating 50 miles west of where we think it’s going to land. It will land where we tell it to, more or less. That should also lessen the impact loads a little bit, but the parasail concept is more about getting the gondola to land in a specific location rather than reducing the loads on the vehicle.

A stretch goal would be to combine the two. However, we’ve definitely figured out that we don’t have the resources or the time to do that. It’s been an iterative process. We’ve been slashing launches and designs out of our schedule as we’ve gotten farther into this. We’ve definitely been learning that it takes a lot of effort just to launch one balloon gondola.

APPEL News: How does your Rocket U project fit into your daily work at Glenn?

Bury: Whenever I have a spare moment, I’m spending it on Rocket U. Our team does a lot of our meetings at lunchtime. We always have a team meeting every Monday morning and it’s just kind of people stepping up to help. We have three folks who are acting as our project managers to help direct all of the work that needs to be done. They basically ask for volunteers to help do work and people step up as their schedules allow. We fit work in wherever we can.

It’s challenging to get things done because we are split between Rocket U and our day jobs, but it’s also very rewarding because we’re able to learn that we can multitask and we can still get things done.

APPEL News: What is your role on the team?

Bury: Right now, I’m one of the workers. Where we are in the design process, we haven’t designed the vehicle yet and we’re working towards deciding if we’re going to do the airbag system or the control system. Until we make that decision, we can’t really design our vehicle because the vehicle design is going to be different depending on which option we choose.

We’ve been collecting cost information to get an estimate for each of the options and figure out which one will fit within our budget. Once we have that nailed down, then we’ll start to delve into roles and responsibilities and start to assign people a piece of the work that they’re going to own. Right now, we’re just writing requirements and doing searches for costs. It’s been chaotic at times, but we’ve organized ourselves enough to move forward and get things done.

APPEL News: Have you met new people at Glenn who are working on the Rocket U team?

Bury: Yes, most of my teammates are people I’d never met before. I’ve worked with some of the folks on the team who have been around Glenn for a while, but we also have some very new people who have been at NASA like six months to a year. It’s been great to connect with other early-career employees and get their insight on the agency. I’ve been here six years, so it’s great to see that fresh enthusiasm because reminds me why I came to work here. Everyone is very excited about the project.

APPEL News: Has anything about this experience surprised you so far?

Bury: How hard it is to plan. We started out with three or four balloon gondola launches and then we realized that wasn’t going to work, we’ll have to do two. As we’re starting to lay out our schedule and do some of our work writing requirements, we’re beginning to realize that we’re not going to be able to do two, and that we’re going to be lucky if we do one launch. It’s just been eye-opening how much work goes into something that seems so simple on paper.

When we started to actually sit down and plan out what we need to do and how much is it all going to cost, we found that it costs a lot more than we thought. One cost estimate that we have right now is about three times the budget that is available, so we’re learning that we didn’t have a good concept of how much these types of projects cost. These are things that we don’t normally think about in our day jobs. Many of us are either researchers or analysts so we don’t necessarily buy equipment or build things.

APPEL News: Is there anything we haven’t asked you that you’d like to add?

Bury: Really, we are just so thankful to the APPEL program. It’s been such a great, great opportunity to get some hands-on experience, see the whole lifecycle, and learn how to function as a team. That’s been a big one: Learning how to function as a team. I remember in the beginning that we had meetings about how we were going to make decisions. We had to make a decision on how we were going to make decisions. These are things that you don’t think about because usually it’s the project manager that does that. Now we’re the project manager and we just kind of have to figure it out. There’s not a whole lot of hand-holding where people are telling us, “You need to do this” or “You need to do it that way.” We have mentors available to us if we need them, but they’re not directing us. It’s all on us.

This is just such an awesome opportunity to be learning through doing and learning through making mistakes. I think I can speak for the whole team in that we’re very thankful for this opportunity.

Learn more about Rocket University.

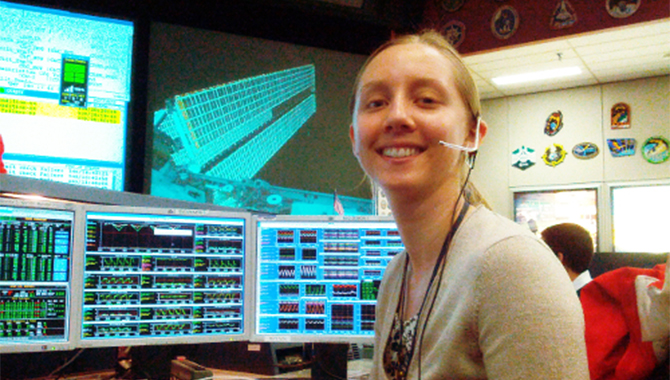

Kristen Bury sitting on the SPARTAN (Station Power, Articulation, and Thermal Control) console in Mission Control at Johnson Space Center in 2013.

Featured Photo Credit: NASA