I was a new engineer at one of NASA’s contractor sites, straight out of college and ready to conquer the Agency. Of the 120 engineers there, I was the only female. To say I stuck out is putting it mildly.

At the time, I was assigned the repairs on the “burn pit” fence. The company burned a lot of propellant, and the fence was in a constant state of damage. Not very stimulating or challenging work, but I was new and what did I know? I received a few other projects, mostly uninteresting stuff, the installation of a sidewalk, repairing a lead floor. I was not sure how to go about getting more challenging design jobs, but soon I was feeling like something had to give.

Months went by and a seasoned facilities engineer (i.e. near retirement) was requested by his supervisor to mentor me. I don’t know anything about what led to this, only that one day he came up to me and said he was going to “take me under his wing.” His name was Harold; he smoked cigars, dressed a bit scruffy, looked cross-eyed at the world, and when he spoke he relied heavily on expletives. Did this have something to do with my being the only female? I’m not sure, but I suspect it did. Maybe they thought because of my gender I needed a helping hand. Unsure whether I should be offended or grateful, I decided not to let it affect my core beliefs or rattle my self-confidence.

Harold definitely wasn’t part of the “crowd,” as such there was. He didn’t get along well with many of the engineers, perhaps because it was a fairly young crowd and most engineers come out of school a bit arrogant, especially towards people without an academic degree, like Harold. He had no formal education as an engineer, just a lifetime of construction management experience.

The first day he took me out in the field to a major facility modification he was responsible for. He showed me how to read the blueprints for this type of job. With Harold you had to learn quickly; he wasn’t about to waste his time, and he was unforgiving if you had trouble keeping up. Old school all the way, Harold expected me to learn what I needed and use it right then on the job.

After introducing me to the contractors, he walked me through the plans and the construction site. He left it up to me to check on the site per his instructions. On occasion, he guided me through some of the more critical issues, such as my weld inspections at the top of the support I-beams. Some issues, such as investigating “fair wages,” insurance benefits, and safety practices of the on-site contractor workers, I conducted on my own after I got his instructions. Would I have known to do these things with only a college diploma to call myself an engineer? Forget it. These were things you learn from experience. Fortunately for me, Harold had a wealth of it and was willing to share it generously.

Later, Harold included me in another major modification, this time to the “tank farm” for the storage, weigh-up, and loading of the two main ingredients of the Space Shuttle rocket motors. Once again he introduced me to the contractors, went over the design and construction plans, and then turned over much of the responsibility of the modification oversight to me. Naturally, he retained ultimate responsibility and monitored the activity closely enough, so that I knew I would not be left in a position to make a catastrophic decision or miss something serious. On one occasion, for instance, there was a discrepancy between the blueprints and the actual physical configuration. Harold resolved the issue but made sure I understood his methodology. He was right-on with his proposal and dealt eloquently, despite his usual penchant for expletives, with the contractor’s concerns. On this occasion and others, I learned from Harold how to have a firm, but mutually respectful, relationship with contractors, and how to negotiate compromises.

But the most important lesson I learned from Harold was still to come. Like many of my co-workers, I had a backlog of jobs that got pretty deep, some of which had to be relegated to the bottom of the pile because they were insufficiently funded or scoped. Moreover, a few of the area managers had presented operational concerns to me and asked me to look into possible modifications. In some cases they had submitted work orders, which got bogged down somewhere, and in the other cases they hadn’t bothered to initiate a work order due to the lack of funding or the length of time it would take to eventually get through “the system.” They were frustrated, as I was, with the documentation and funding “wickets,” which regularly resulted in changes not occurring or taking many months or even years.

Considering the hazardous environments most workers had to face, I felt that some of the modifications needed to be addressed, and quickly. However, I had no idea how to get a work package through “the system” or get funding. Like every organization, we had “bean counters,” but they proved to be a dead end. Enter Harold.

“I’m going to walk you through finance and introduce you to everyone,” he said to me one day. I really didn’t understand the significance of this gesture at that time, but I quickly found out how invaluable that was and would be throughout the rest of my career. I not only learned every step a work order takes, but every step in the funding approval process, as well as when funding is not available how to find alternative sources, how to make my packages a priority, and, most importantly, WHO to talk to.

Over and over I have found it to be the individual who makes the difference, no matter where, when, or what you’re involved with. By introducing me personally to each individual in the flow, Harold established my credibility with them and gave me the opening for personal work relationships. I became a “known” person and my reputation was associated with his. Thank goodness his reputation was golden.

Individuals have their own idiosyncrasies or attitudes that may be disagreeable or may just be a response to events at that moment in time for them. I learned while being mentored by Harold to identify “where to draw the line” and to be tolerant of another’s frame of reference when trying to get a job completed. For instance, when Harold introduced me to the head of finance, I took the opportunity to ask him for funding of a project. He said he’d give me the funds I requested only if I gave him a hug. Naturally, he didn’t ask Harold for a hug, but I trusted that Harold would indicate if the person was disreputable or way out of line. I gave him a hug in good humor, got my funding, and established a very good relationship for future requests. Incidentally, he didn’t do it again, which confirmed my assessment that the introductions set up a sort of jovial “tone” and nothing more.

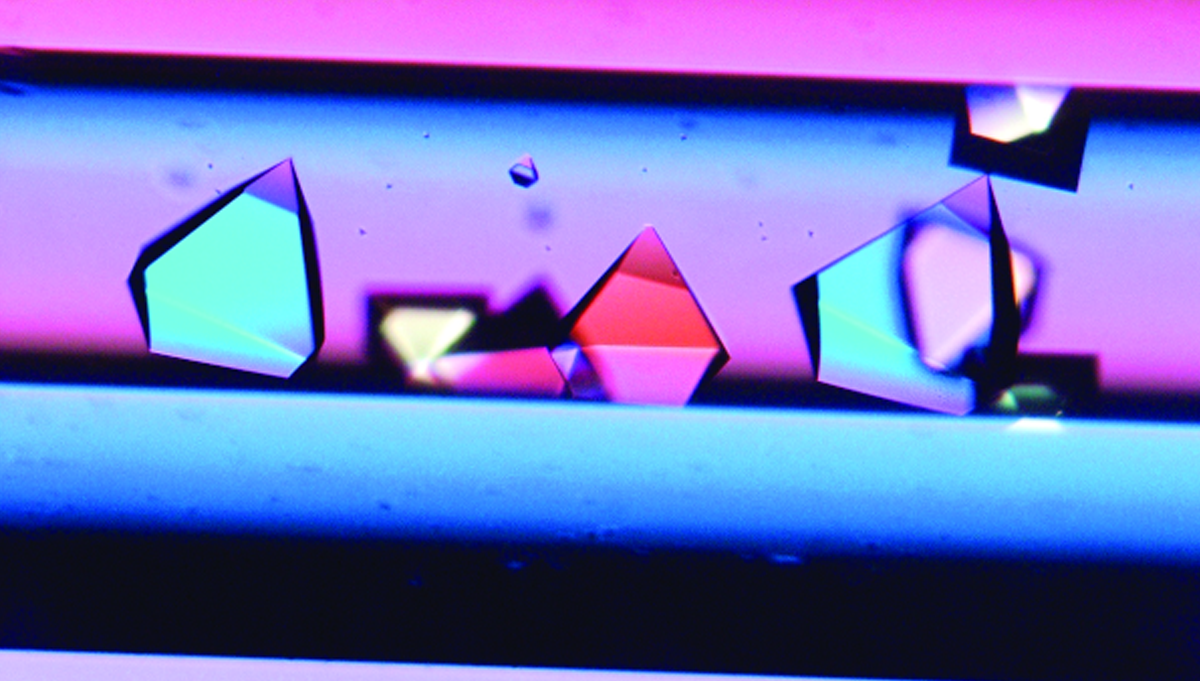

Twelve months after taking me under his wing Harold retired. On my next project I was assigned to work as co-engineer on the design and construction of the High Energy Propellant Testing and Forming Facility with a budget limitation of $1M. The facility occupancy involved a variety of hazards ranging from office space to propellant milling and tension testing to storage of high-energy propellants. The facility was completed on budget and within schedule, and was not only featured in the company’s national newsletter, but also visited by the company’s senior executives. After completion of the High Energy Propellant Testing and Forming Facility, the same engineer and I were assigned the design and construction of the new Nitroglycerin Weigh-up Facility. At that time, I was also the Engineer-In-Charge of numerous facilities. All of this happened in less than three years. I suppose you could say I had come a long way from the “burn pit” fence.

I am convinced I would not have had the capabilities or the opportunity to work on these projects had it not been for the mentoring I received from Harold. I also believe we would not have been granted the latitude in design and construction we had if not for what I learned from Harold in combination with the experience of the co-designer. What’s more, I understood clearly how to obtain both support and funding, without which these projects would have been difficult, if not impossible, to complete. What I got out of my experience with Harold no doubt accelerated my career and has made me a better project manager.

I didn’t choose my mentor, nor would I have guessed one could have such an impact, but I thank my lucky stars he took the time to mentor me.

Lessons

- Great mentors aren’t always easy to spot, and they can come from a very different background.

- The mentor can provide you a jump start in relationships by your association with him or her.

- Exercise patience and diligence; you may not recognize the benefits until much later.

- Individuals make the difference.