By Dennis McCarthy

From 1983 to 1989, I was deputy project manager at Goddard Space Flight Center for the Cosmic Background Explorer (COBE), the spacecraft that enabled NASA scientist Dr. John Mather and his colleague Dr. George Smoot (University of California/Berkeley) to investigate the origin of galaxies and stars and offer the most conclusive evidence of the big bang theory to date. Mather and Smoot were awarded the 2006 Nobel Prize in Physics for this research.

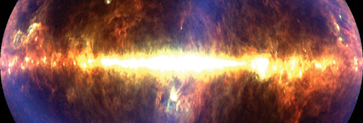

COBE was launched into an Earth orbit in 1989 to make a full sky map of the microwave radiation left over from the Big Bang.

Image Credit: NASA

The COBE project was the most demanding of my career because it had to be so precise. To achieve its goal of measuring diffuse infrared and microwave radiation from the early universe, it had to be essentially perfect. We handled this almost impossibly stringent requirement by performing a lot of analysis. We analyzed every circuit and did Failure Modes Effects Analyses (FMEAs) of all the things we thought could possibly happen.

You could never have written a specification on a contract or a statement of work to have someone build COBE. It was Nobel Prize science that depended on groundbreaking technology. Nothing like the instruments we needed had ever been built before. We had a 100% failure rate along the way, when we put the instruments in test dewars and tried to test materials’ properties and electronics. You couldn’t afford to have a contractor do that.

Because COBE had cryogenic instruments with a dewar full of liquid helium cooled to a temperature of 2 kelvin (-271°C), we had to be sure everything was right before we cooled it down; otherwise, it would have taken six weeks to warm it back up and then cool it down again. So we were very sensitive to developing plans and procedures to test the satellite and the instruments. Even though we didn’t have all the requirements in the eighties that projects have today, we were very conscious of all the analyses required to ensure the spacecraft was noise-free and would perform the way we predicted it would.

COBE was designed to launch from Vandenberg Air Force Base on the Space Shuttle, which would insert it into a polar orbit. The Challenger accident forced us to completely rethink every aspect of the spacecraft’s design, including moving from a shuttle launch to a Delta rocket. We’d already built a full-scale mock-up of the COBE spacecraft for a shuttle launch. After the accident, we had to do a lot of additional analyses to reconfigure the spacecraft for an entirely new launch vehicle and orbital insertion. The mock-up was actually used to integrate and test all spacecraft subsystems while we continued to develop the instruments in parallel.

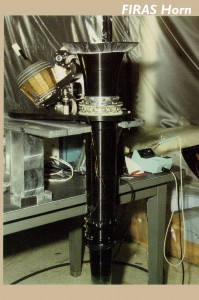

A close-up of COBE’s Far Infrared Absolute Spectrophotometer (FIRAS) horn antenna, which made a precise measurement of the spectrum of the cosmic microwave background radiation.

Photo Credit: NASA

The processes and procedures used to conduct the test program were extremely thorough. For example, when we finished the tests needed to qualify the complete satellite, we left it in a radio frequency clean room—a shielded environment that blocks extraneous electromagnetic signals—and let it run for two weeks. We were encouraged to do this to help scientists understand all the characteristics of the satellite. Because what they were trying to measure was so minute and the measurements had to be so accurate, they needed to be certain that their results reflected cosmic background radiation, not “noise” from the satellite. This two-week test gave the scientists the opportunity to learn the satellite’s idiosyncrasies.

We also had an open-door policy that worked remarkably well. The project management team was very sensitive to the fact that we wanted everyone in the program to come to us at any time if they found something they didn’t understand or if they didn’t agree with our decisions. People could come talk to me whenever they wanted, and they did. We relied on the technicians, engineers, and designers to be our eyes and ears, keeping tabs on what went on every day. They were all empowered to feel it was their spacecraft. When the workforce feels they own the spacecraft, they take care of it, they test it adequately, and they don’t take shortcuts.

I gave our quality assurance (QA) personnel the authority to shut down work whenever they felt the need. Once or twice they called me from the clean room to say they were going to shut down work for a day because the pressure of the project was causing someone to want to move on and not finish something or skip steps instead of being thorough. The QA team did a marvelous job. They had a lot to do with the success of this program.

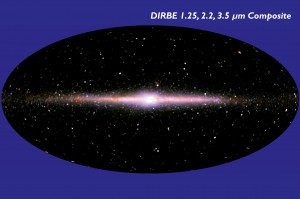

False-color image of the near-infrared sky as seen by the Diffuse Infrared Background Experiment (DIRBE), a COBE instrument that obtained data that can be used to seek the cosmic infrared background radiation and study the structure of the Milky Way Galaxy and interstellar and interplanetary dust.

Photo Credit: NASA

In-house development is critical to building the skill base of the NASA workforce. Goddard Deputy Director Mike Ryschkewitsch and Director of Engineering Orlando Figueroa were each responsible for a part of COBE. There’s no better proof of the value of hands-on work. The only way they could have developed their high level of engineering judgment was through work on an in-house program. In-house projects also make you a much smarter customer. You cannot go out and monitor prime contractors and distinguish what the problems are if you haven’t done the work yourself.

COBE is a success because the satellite led to a major discovery. Looking back, I can say it succeeded because of the team’s talent and dedication, despite disagreements and misunderstandings caused by the absence of clearly spelled out roles and responsibilities, such as those provided by the new 7120.5D. There were people in the line organizations who thought they had more responsibility for COBE than I thought they should have, and as a result there were lots of conflicts. Clarity about who does what allows everybody to be more comfortable about expectations, which leads to a better working environment where the focus can remain on accomplishing the mission.