By Roger D. Launius

When Congress passed the National Aeronautics and Space Act of 1958 and President Dwight D. Eisenhower signed it into law, few politicians understood the magnitude of the complexity required to carry out the broad mandate it had given the new National Aeronautics and Space Administration (NASA).

Engineers inspect and test a boilerplate Mercury space capsule. Project Mercury spanned five years and achieved the goal of orbiting Earth in a manned spacecraft. Former NASA Administrator T. Keith Glennan remarked about Mercury that he had been associated with “one of the best organized and managed” programs.

Photo Credit: NASA

It directed the space agency to expand human knowledge about the cosmos, develop and improve the performance of space technology, and make the “most effective utilization of the scientific and engineering resources of the United States, with close cooperation among all interested agencies of the United States in order to avoid unnecessary duplication of effort, facilities, and equipment.” Congress did not, however, tell NASA how to accomplish those difficult tasks. The Agency has been working ever since to develop approaches to management that achieve those objectives.

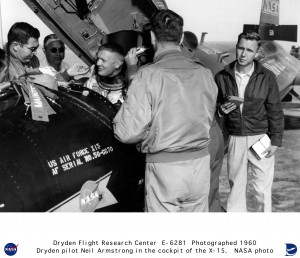

Initially, NASA applied principles of management learned during nearly fifty years of experience in the National Advisory Committee for Aeronautics (NACA), whose members made up the majority of NASA in its first years. This government institution, with its three research centers and single flight test facility, had a breadth of experience undertaking aeronautical research, but by far its largest management effort to date had been the X-15 hypersonic flight research project begun in the latter 1950s.

Its approach to the X-15 as well as to its other programs had been to empower an authoritative project manager to oversee all aspects of the effort and to rely on that individual to organize resources as deemed appropriate, to acquire personnel seen as necessary to the project, and to bring it to successful operational status. In the case of flight research projects, this involved building the research vehicle and conducting a measured program of research and technical publication preparation. The method worked well for the relatively modest projects of NACA.

The newly established NASA followed basically the same approach in 1958 during its first human space project, Mercury, placing it under the direction of Robert Gilruth’s Space Task Group at the Langley Research Center and giving Gilruth virtually total control to ensure its success. This proved a difficult but “doable” task, as Gilruth had to structure the project to involve other teams at different NASA Centers, something not common in the NACA experience.

Just six days after NASA was established on October 1, 1958, Administrator T. Keith Glennan approved plans for Mercury. On October 8 he gave Gilruth authority to proceed. Thirty-five key staff members from Langley, some of whom had been working on the military human space flight plan, were transferred to the new Space Task Group, as were ten others from the Lewis Research Center near Cleveland, Ohio. These forty-five engineers formed the nucleus of the more than 1,000-person workforce that eventually took part in Project Mercury. As Glennan wrote in his diary, “The philosophy of the project was to use known technologies, extending the state of the art as little as necessary, and relying on the unproven Atlas. As one looks back, it is clear that we did not know much about what we were doing. Yet the Mercury program was one of the best organized and managed of any I have been associated with.”

Neil Armstrong sits in the X-15’s cockpit in this 1960 photo. The X-15 hypersonic research project was one of NASA’s largest management efforts.

Photo Credit: NASA

Such a small program, imbued with outstanding leadership from Robert Gilruth and staffed by a dedicated team of engineers, succeeded well. But its relatively unstructured approach would not do for the massive Apollo program that took Americans to the Moon in the 1960s and 1970s. Instead, NASA borrowed the program management concept used by the Department of Defense in building the first intercontinental ballistic missiles (ICBM). To accomplish its goal, NASA had to meld disparate institutional cultures and approaches into an inclusive organization moving along a single, unified path. Each NASA installation, university, contractor, and research facility had its own perspective on how to go about the task of accomplishing Apollo.

The central figure in implementing this more rigorous approach was U.S. Air Force Major General Samuel C. Phillips, the architect of the Minuteman ICBM program before he came to NASA in 1962. Answering directly to the Office of Manned Space Flight at NASA Headquarters, which in turn reported to the NASA Administrator, Phillips created an omnipotent program office with centralized authority over design, engineering, procurement, testing, construction, manufacturing, spare parts, logistics, training, and operations.

One of the fundamental tenets of the program management concept was that three critical factors—cost, schedule, and reliability—were interrelated and had to be managed together. Many recognized that if program managers held cost, for instance, to a specific level, then one of the other two factors, or both of them to a somewhat lesser degree, would be adversely affected. This held true for the Apollo program. The schedule, dictated by the president, was firm. Since humans were involved in the flights, and since the president had directed that the lunar landing be conducted safely, the program managers placed a heavy emphasis on reliability. Accordingly, Apollo used redundant systems extensively so failures would be both predictable and limited in their effects. The significance of both of these factors forced the third factor, cost, much higher than might have been the case with a more leisurely lunar program such as had been conceptualized in the latter 1950s. As it was, this was the price paid for success under the Kennedy mandate, and program managers made conscious decisions based on knowledge of these factors.

The program management concept was recognized as a critical component of Project Apollo’s success in November 1968, when Science magazine, the publication of the American Association for the Advancement of Science, observed the following:

In terms of numbers of dollars or of men, NASA has not been our largest national undertaking, but in terms of complexity, rate of growth, and technological sophistication it has been unique. …It may turn out that [the space program’s] most valuable spin-off of all will be human rather than technological: better knowledge of how to plan, coordinate, and monitor the multitudinous and varied activities of the organizations required to accomplish great social undertakings.

Understanding the management of complex structures for the successful completion of a multifarious task was an important outgrowth of the Apollo effort.

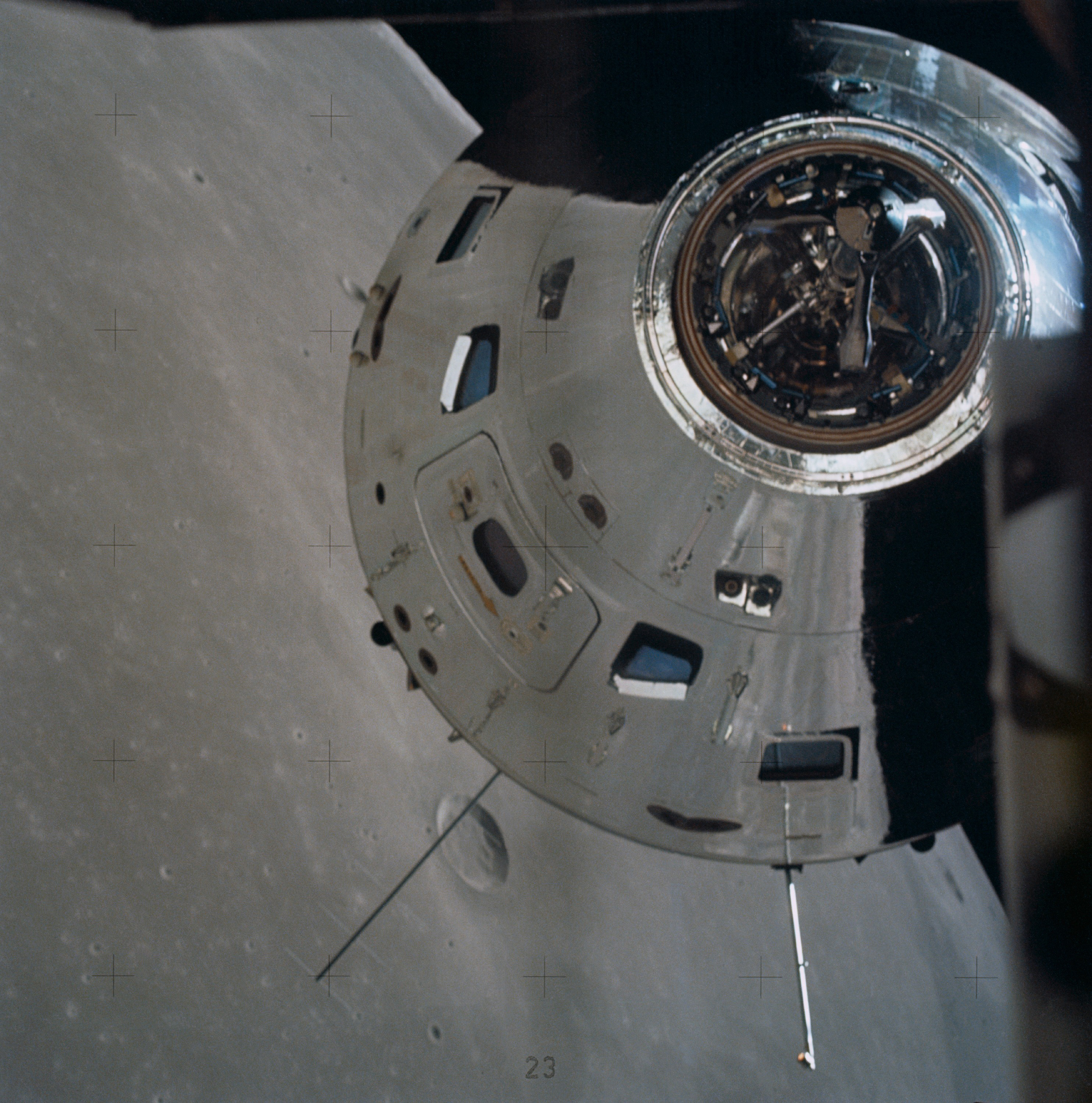

The Apollo 11 Command/Service Module is mated to the Saturn V Lunar Module Adapter. NASA borrowed the program management concept used by the Department of Defense to establish a strong management model for Apollo.

Photo Credit: NASA

Under Phillips, this management concept orchestrated more than 500 contractors working on both large and small aspects of Apollo. For example, the prime contracts awarded to industry for the principal components of just the Saturn V included the Boeing Company for the S-IC, first stage; North American Aviation, S-II, second stage; the Douglas Aircraft Corporation, S-IVB, third stage; the Rocketdyne Division of North American Aviation, J-2 and F-1 engines; and International Business Machines (IBM), Saturn instruments. These prime contractors, with more than 250 subcontractors, provided millions of parts and components for use in the Saturn launch vehicle, all meeting exacting specifications for performance and reliability. The total cost expended on development of the Saturn launch vehicle was massive, amounting to $9.3 billion. So huge was the overall Apollo endeavor that NASA’s procurement actions rose from roughly 44,000 in 1960 to almost 300,000 by 1965.

Getting all the personnel elements to work together challenged the program managers, regardless of whether or not they were civil service, industry, or university personnel. Various communities within NASA differed over priorities and competed for resources. The two most clearly identifiable groups were the engineers and the scientists. As ideal types, engineers usually worked in teams to build hardware that could carry out the missions necessary for a successful Moon landing by the end of the decade. Their primary goal involved building vehicles that would function reliably within the fiscal resources allocated to Apollo. Again as ideal types, space scientists engaged in pure research and were more concerned with designing experiments that would expand scientific knowledge about the Moon. They also tended to be individualists, unaccustomed to regimentation and unwilling to concede gladly the direction of projects to outside entities. The two groups contended with each other over a great variety of issues associated with Apollo. For instance, the scientists disliked having to configure payloads so they could meet time, money, or launch vehicle constraints. The engineers, for their part, resented changes to scientific packages added after project definition because these threw their hardware efforts off kilter. Both had valid complaints. They had to maintain an uneasy cooperation to accomplish Project Apollo.

The scientific and engineering communities within NASA were not themselves monolithic, and differences among them thrived. Add various other groups representing industry, universities, and research facilities, and the result was widespread competition among parties at all levels striving to further their own scientific and technical aims. The NASA leadership generally viewed this pluralism as a positive force within the space program, for it ensured that all sides aired their views and encouraged the honing of positions to a fine edge. Competition, most people concluded, made for a more precise and viable space exploration effort. There were winners and losers in this strife, however, and sometimes ill will was harbored for years. Moreover, if the conflict became too great and spilled into areas where it was misunderstood, it could be devastating to the conduct of the lunar program. The head of the Apollo program worked hard to keep these factors balanced and to promote order so NASA could accomplish the presidential directive.

Another important management issue arose from the Agency’s inherited culture of in-house research. Because of the magnitude of Project Apollo and its time schedule, most of the nitty-gritty work had to be done outside NASA by contractors. As a result, with a few important exceptions, NASA scientists and engineers did not build flight hardware or even operate missions. Rather, they planned the program, prepared guidelines for execution, competed contracts, and oversaw work accomplished elsewhere. This grated on those NASA personnel oriented toward research and prompted disagreements over how to carry out the lunar-landing goal. Of course, they had reason for complaint beyond the simplistic argument of wanting to be “dirty-handed” engineers; they had to have enough in-house expertise to ensure program accomplishment. If scientists or engineers did not have a professional competence on par with the individuals actually doing the work, how could they oversee the contractors creating the hardware and performing the experiments necessary to meet the rigors of the mission?

One anecdote illustrates this point. The Saturn second stage was built by North American Aviation at its plant at Seal Beach, California, shipped to NASA’s Marshall Space Flight Center in Huntsville, Alabama, and there tested to ensure it met contract specifications. Problems developed on this piece of the Saturn effort and Wernher von Braun began intensive investigations. Essentially his engineers completely disassembled and examined every part of every stage delivered by North American to ensure it had no defects. This was an enormously expensive and time-consuming process. The stage’s production schedule ground almost to a standstill, jeopardizing the presidential timetable. When this happened, then—NASA Administrator James E. Webb told von Braun to desist, adding, “We’ve got to trust American industry.” The showdown came at a meeting where the Marshall rocket team was asked to explain its extreme measures to Webb. While doing so, one of the engineers produced a rag and told Webb that “this is what we find in this stuff.” The contractors, the Marshall engineers believed, required extensive oversight to ensure they produced the highest-quality work. A compromise emerged that was called the 10 percent rule: 10 percent of all funding for NASA was to be spent to ensure in-house expertise and in the process check contractor reliability. The project management of the Apollo program involved these major features:

- A well-staffed headquarters group with strong systems engineering and integration capabilities

- Strong field centers using extensive in-house technical capability

- Independent contractors relied upon to do their work effectively

- Extensive checks and balances, inspections, safety reviews, systems engineering, and configuration management

- Recruitment of exceptional engineers and scientists, allowing them wide latitude in taking initiative and responsibility

- Hands-on engineering at all levels

- Extensive research and testing of components and systems

- Practices that encouraged constant learning (such as creating new challenges on each flight and learning through failure)

NASA added to that an aggressive program-planning effort that ensured clear objectives, well-defined lines of authority/accountability, and consistent and objective management. It also necessitated complex systems integration emphasizing orderly, clear, reliable, and consistent oversight, configuration control, decision making in a timely and effective manner, and omnipresent communication and accountability.

The program management concept worked well, but it was enormously expensive. NASA officials realized at the conclusion of the Apollo program that they would never again have the resources that had been made available for the Moon landings, and they had to find another means of accomplishing their projects without such a broad effort. Perhaps most important, the experience of Apollo suggested that this approach was fragile and could easily become flawed if its managers failed to manage practices strictly. In the face of conflicting organizational demands, the practices so successful in Apollo would tend to disappear. Maintaining such practices requires constant vigilance and adjustment.