By Carol Anne Dunn and Giny Cheong

When the Applied Physics Laboratory (APL) at Kennedy Space Center developed the laser scaling device for the Space Shuttle program, the inventors had no idea that the invention would become commercially successful with law enforcement and crime scene investigation teams.

After a storm caused extensive hail damage to the shuttle’s external tank, NASA Space Shuttle operations personnel wanted to measure the extent of the damage. Although telephoto lenses clearly showed the damage to the external tank, the image contained no reference objects to determine the exact size of the dents. In many photographic situations an object such as a ruler is placed within the frame so the viewer will have a visual indication of the scale of the other objects in it. This procedure was not possible in this situation, however, as several areas were physically inaccessible. Personnel needed to know the scale of the damage to determine whether repairs would be necessary, so the operations team called on APL’s innovative problem-solving abilities to help.

Dr. Robert Youngquist, the lead inventor, explained, “Our lab is unique here at Kennedy, and there aren’t any other labs that do what we do. When problems arise that aren’t specific to any lab, for example corrosion or chemistry, or when strange problems arrive, they are brought to our lab. Historically, we’ve fallen into the role as a catchall to solve problems that don’t fit or aren’t supported by the more specific labs.”

Two shuttle engineers, Charles Stevenson and Jorge Rivera, came to Dr. Youngquist and APL with the idea for the laser scaling device. Dr. Youngquist recalled, “They hadn’t thought it all through very well, but they had realized that by using laser beams, they could get some kind of scaling information. They posed the problem and suggested laser beams as a solution. I built the system in my lab using lab parts and verified that it met the requirements [one-sixteenth-inch resolution at 80 feet].” William Haskell and Robert Cox built the first prototype while Dr. John Lane, Kim Ballard, and Dr. Youngquist created the software, which converts the pattern in the image and computes the distance scale for the entire image.

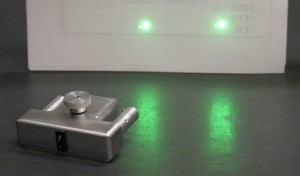

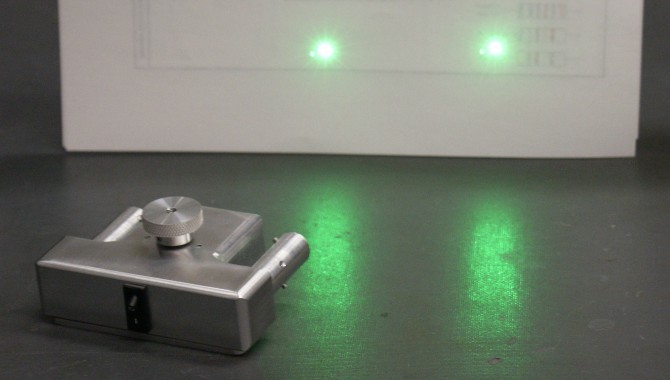

The resulting device attached directly onto a camera or any other observation instrument to project parallel laser lines into the camera’s field of view. The lines indicated a known distance and generated a set of evenly spaced laser spots on the object being photographed. The resulting image projected a built-in scale to show the size of the object being seen. The accompanying software converted the pattern in the photo and computed the distance scale, saving valuable time in establishing and documenting measurements. The laser scaling device essentially placed a virtual ruler in the field of view that allowed the operations personnel to determine the scale of the object and measure the extent of the external tank’s hail damage with more than one-sixteenth-inch accuracy.

The Kennedy APL team also tested several other design prototypes, including multiple lasers versus a single laser sent through beam-splitting optics and plastic versus metallic housings for the battery. The experimentation resulted in a multilaser assembly that used four lasers, as requested by shuttle operations personnel, and subsequent versions that used two lasers. Dr. Youngquist said, “We always try to find simple solutions. A lot of the hardware that we build, a lot of the reason people like us, is because we find simple solutions.”

Dr. Youngquist also cited several factors for his laboratory’s success: “Ingenuity and mechanical design as well as our breadth of background and years of experience are vast here. We also provide a strong customer experience—we listen to them and the problems that they bring to us. Other labs fix things by using what they know, while we will learn things or bring problems to other labs when it’s outside our realm of expertise.”

In September 2003, NASA signed a nonexclusive license agreement with Armor Forensics, a subsidiary of Armor Holdings, Inc., for the laser scaling device under the Innovative Partnerships Program. Coupled with a measuring program, also developed by NASA, the unit provides crime scene investigators with the ability to shoot photographs at scale without having to physically enter the scene, analyzing details such as bloodspatter patterns and graffiti. This ability keeps the scene’s components intact and pristine for the collection of information and evidence.

The laser scaling device elegantly solved a pressing problem for NASA’s shuttle operations team and also provided industry with a useful tool. For NASA, the laser scaling device is still used to measure divots or damage to the shuttle’s external tank and other structures around the launchpad. When the invention also met similar needs within industry, the Innovative Partnerships Program provided information to Armor Forensics for licensing and marketing the laser scaling device. Jeff Kohler, technology transfer agent at Kennedy, added, “We also invited a representative from the FBI’s special photography unit to Kennedy to meet with Armor Forensics and the innovator. Eventually the FBI ended up purchasing some units. Armor Forensics is also beginning to receive interest from DoD [Department of Defense] for use in military crime scene investigations overseas.”

For information regarding the laser scaling device, please call Jeff Kohler, Technology Transfer Agent, at 321-861-7158.

About the Author

|

Carol Anne Dunn currently works as a project specialist in the Technology Transfer Office at Kennedy Space Center. She is also the awards liaison officer for the Inventions and Contributions Board. |