By Kerry Ellis

Since the advent of space exploration, Mars has been a tantalizing goal. Astronomers had been peering at Mars for centuries, trying to discern its features; science-fiction novels had been filling the human imagination with ideas of life on the red planet’s harsh surface for fifty years before the first orbiter attempts were made. But Mars did not make it easy for us to approach. Between 1960 and 1974, the U.S. and Soviet space programs made twenty-two attempts to reveal some of the planet’s secrets. Fifteen of those missions failed.

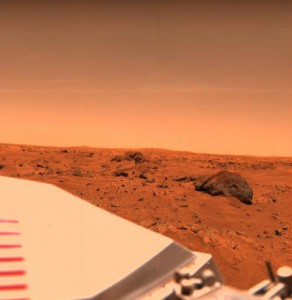

The U.S. Mariner missions provided glimpses of the planet. Mariner 4 accomplished the first successful Mars flyby and returned the first images of another planet from deep space. The images were taken from orbit, which gave too broad a view to distinguish small surface details—data necessary to determine safe landing sites. “We had no visibility and no imagery,” said Viking project manager Jim Martin. “Look at the first color picture, and you see ‘Big Joe’ 25 to 30 feet away. If we’d hit that rock, Viking would have been smashed. We had no visibility. Just a lot of luck.”

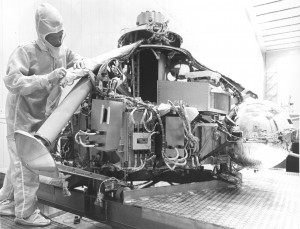

The planetary landing spacecraft Viking I under assembly at Martin Marietta Aerospace. Learning about instrument sensitivity during the Ranger missions led to the use of white tech suits during assembly, which is a standard practice today.

Photo Credit: NASA

Along with luck, the Viking team had talent, intelligence, and an avid desire to solve the mysteries of Earth’s near neighbor. A key driver and source of excitement for those involved was the burning question of whether life existed, or could exist, on Mars. The search for life presented its own difficulties, including the sterilization of all lander parts to avoid bringing Earth contaminants to Mars. This requirement eliminated about 90 percent of standard industry parts they could use for fabrication, according to Ansel Butterfield, the Viking parts coordinator. Creating technology that did not yet exist, finding cost-effective solutions, and explaining requirements to manufacturers became additional hurdles.

Butterfield recalled a conversation he had with a man from General Electric (GE), which was producing televisions at the time. While comparing notes about an electronic voltage amplifier, which would cost $50 each for Viking, the GE representative claimed he could get them for 50 cents. “I explained they were a bit different,” said Butterfield in a NASA interview. “When he asked, ‘What’s the difference between your electronics and mine?’ I told him, take your television set, stick it in the oven and bake it at 250 degrees for twenty-four hours, put it in a deep freeze for a year, then snap it and roll it down a flight of stairs, dump it out a second-floor window, and expect it to play.”

The Viking orbiters and landers were not going to have an easy journey.

Designing, Fabricating, and Testing

Viking was a huge undertaking consisting of two orbiters carrying two landers. The orbiters would capture and relay information about the Mars surface that would allow the mission team to determine safe landing sites for both landers. It was a complex mission to design and fly, especially considering the technology available in the late sixties to early seventies.

Creating the landers presented a larger challenge. While engineers designing the orbiters could pull from their experience designing Mariner, the lander team was breaking new ground. The Viking landers were heavier and more complex than NASA’s earlier lunar lander, Surveyor. They also needed to travel much farther than the earth’s moon and had to descend safely through the Martian atmosphere. The relative thinness of the atmosphere made that, in some ways, a more difficult challenge than reentry into Earth’s atmosphere, which had been solved during Apollo. These factors would affect the overall design and fabrication of the Viking landers, as well as the scientific instruments. Martin made certain the science team was involved in discussions early on as the engineers drafted requirements.

One of the most challenging instruments was the gas chromatograph-mass spectrometer (GCMS), which spent some time on Martin’s infamous Top Ten Problems list. A combination of two instruments in one, the GCMS was a crucial instrument for the science the team wanted to achieve with Viking. It would separate, analyze, and identify different molecules from a Mars soil sample; it was cutting-edge science. So cutting-edge, the original GCMS was the size of a room. The Viking scientists and engineers had to shrink it to fit inside a 1-foot cube. They overcame several technical issues that resulted in a GCMS flying on each lander and returning data to Earth successfully.

The innovations that came out of Viking went beyond the creation of complex scientific instruments; they included new solutions in communication, engineering, and mission design made necessary by the complexity of the mission. One of those innovations was the Viking Automatic Data System, an early use of computer systems to share and review documents. “This is what we routinely do today, but remember this was 1970,” said Gus Guastaferro, the Viking business manager. “They were having a hard time developing it, and I recommended we drop it. Jim [Martin] looked around the room and said, ‘Is there anybody else in the room that has an opinion that is also against progress?’ And Tom [Young] said, ‘Jim, I think it’s a great idea and we should pioneer that kind of spillover effect.’ And he was right,” Guastaferro said. “It was the type of visionary thing that happened in Viking that changed all of us. Jim had an obligation that we had to grow as an organization and introduce new tools and new ways of doing business.”

Viking also introduced a revolutionary approach to flight planning when the launch date slipped from 1973 to 1975 due to budgetary reasons. Norm Crabill, part of the mission analysis and design team, recalled that 1973 was a “low energy to Mars year,” meaning the journey would take only six months to complete, compared with nine or ten months in 1975. “I had the duty of telling Jim he had to go back to the president and tell him we had to launch in 1973 because you couldn’t get there from here in 1975,” recalled Crabill. “My education broadened immediately when the answer was, ‘You don’t understand. You find a way to get there in 1975.’” They put together a team to determine another way to accomplish the journey and discovered what is now called a Type II trajectory, which means flying a spacecraft more than halfway around the sun. “Everyone at NASA got involved because the idea was so radical,” said Crabill. “I like to think it broke the mold on interplanetary trajectory design.”

Even after the rigorous testing that led to Viking’s successful launch in 1975, engineers and scientists worked through scenarios of unexpected events that would require quick brainstorming and solutions to keep the orbiters and landers working. “One of the things we did to prepare for Viking, and is still done today, is put together exercises to simulate what would happen in real time to ensure we didn’t forget anything,” said Hugh Kieffer, principal investigator for the infrared thermal mapper. One of the exercises covered the first few days of the surface mission, which the scientists found somewhat boring. “We had to go to meetings to plan for data we didn’t have,” explained Kieffer.

After more than a day of analyzing imaginary but expected data, those leading the effort dreamed up a concept to make it more thrilling and get the team more involved. At the next meeting, they had the water vapor detector report that its instrument seemed to be out of calibration. Then the spectrometer team reported they were receiving strange values. “So the normal process of regularly planning the next day was suddenly getting requests,” said Kieffer. “We couldn’t follow the plan; we had to change things based on discoveries. We were pushing the flight team out of their comfort zone of regularly planned sequences. By the time the third ‘discovery’ came up, it was clear we’d stressed the operations team to its limit because Gentry Lee, who was in charge of running daily operations, stood up and pounded his fist on the table, shouting, ‘Enough! There will be no more discoveries!’”

Though the team worked hard to anticipate the unexpected, unanticipated problems arose. Ingenuity and foresight helped the team meet those challenges. Jim Cochran, a photographic chemist, recalled one instance where they needed to use a third lander they had kept on Earth for troubleshooting. “We sent a signal for a sampler boom to unhinge on a lander, and it failed,” said Cochran. Worried they wouldn’t be able to gather an important biological sample, they pointed the lander’s camera up at the arm and saw a pin that hadn’t fallen out. “They programmed the lander on Earth to twist and wiggle the boom until the pin fell out, then sent the same program to the lander on Mars. They turned the camera back down to the ground until they saw the pin and knew it had dropped. And that’s what they did with Viking: they came across problems that had never been solved before and solved them,” said Cochran.

It’s About People

In a series of interviews conducted by NASA at Viking’s thirtieth anniversary celebration, many of those involved in the program spoke about the extraordinary team that had been gathered to make breakthroughs in planetary exploration to Mars. Martin, for many the most memorable project manager they ever worked for, said, “We probably had the most talented team of engineers you could find.”

Viking’s success was due to more than having the right people. Everyone worked diligently and collaboratively to find solutions to problems, and they continually learned from previous and on-the-job experience. For example, problems that had arisen on the early lunar Ranger missions were factored into Viking’s fabrication. Bob Crabtree, mission operations manager for Viking’s cruise phase, said, “Quality assurance then [during Ranger] was unheard of. People were even allowed to smoke in the vehicle assembly building. Now we have techs in white suits, but we didn’t know things were that sensitive during Ranger. All the things we learned were factored into Viking, and Viking worked exceptionally well.”

And the team never stopped learning during the mission. “We really learned about longevity of engineering,” said Steve Wall, a camera engineer for Viking. “To maximize lifetime as we rewired parts of Viking to keep it working is the lesson I’d like carried forward, what I’d like us to be remembered for.”

Near the Viking 1 lander on the Chryse Plains of Mars, “Big Joe” stands a silent vigil. This large, dark rock is about 6.6 ft. long and lies about 26 ft. from the spacecraft—a narrow miss during Viking I’s landing.

Photo Credit: NASA

Ed Rinderle, a Viking programmer, attributed some of Viking’s success to the working environment: “We were all gathered in one big bullpen, an open area, no cubicles or partitions. You got to know each other on a different level than had we been separated.”

The team was also thoroughly dedicated to the success of Viking and maintained an intense focus throughout the mission at all levels. A striking example of this focus occurred during a checkout of a lander’s software and computer before it separated from an orbiter. In the middle of this crucial checkout, a red phone connecting directly to the White House rang in Martin’s office. “Jim picks up the phone and a voice on the other end says, ‘Mr. Martin, this is the White House calling …” recalled John Newcomb, who was involved in the mission design and software. “Jim interrupted, ‘You tell President Ford, please, that I do not have any time to speak to him right now—we are in the middle of a lander checkout—and for him to call back in three hours.’ And he hung up on the president. In three hours, President Ford called back,” said Newcomb. “For those of us who had been working with Jim for eight-plus years, it was a no-brainer. Of course the president was going to call Jim back. Jim told him to!”

Teamwork, dedication, creative problem-solving, and rigorous testing all contributed to Viking’s success and the team’s feeling of immense accomplishment when the first lander image from Mars arrived line by line. “Viking convinced me that one can take on a major engineering and science challenge and succeed with the right ingredients,” said Noel Hinners, then NASA associate administrator for space science. “That includes a great leader and a great team. Don’t think anything is so difficult and hard you shouldn’t even try it. With the right planning, people, leadership, and budget, you can do a lot and succeed.”

Interviews were originally conducted by NASA and can be found at http://mars.jpl.nasa.gov/gallery/video/viking30/index.html. For more information regarding the challenges solved on the GCMS, please see the APPEL case study at /items/Viking_GCMS_case_07%2025%2006.pdf.