By Bo Schwerin

One morning in 1990, a group of Glenn Research Center employees arrived to find their workspace upended by an apparent hurricane. Papers were scattered, lights blown out. All eyes turned to the door connecting the office to its neighbor: a 20-foot wind tunnel.

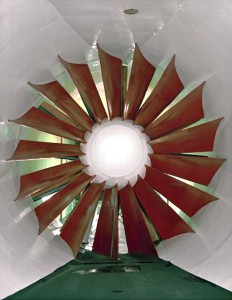

Aerostar’s wind turbines are stall regulated, a feature enabled by the Viterna model.

Photo courtesy NASA Spinoff

The employees did not know it, but they had Dr. Larry Viterna to thank for the state of their workspace. An innovation by the NASA researcher may have led to the accidental trashing of their office, but it would go on to benefit the entire field of wind energy.

Viterna joined NASA in 1977, when growing anxiety over fuel costs and environmental impacts led the U.S. government to explore alternative and renewable energy sources. Prior to the formation of the Department of Energy, the government turned to other agencies to develop solutions. Glenn had a history of energy research stemming from its work in fuel-efficient aeronautics during World War II and in alternative fuels and related aerospace engines at the start of the space age in the 1950s. When Viterna joined the center, it had already assumed the lead role in the nation’s wind-energy program. NASA’s goal was to develop technology for harnessing the wind’s power and transfer it to private industry.

“Our center had an expertise in propellers, propulsion, rotating equipment, and power systems,” making Glenn a natural choice for the job, explained Viterna. The center’s efforts, he said, ultimately laid the foundation for much of the wind technology and industry that exist today.

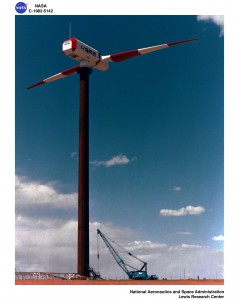

Glenn constructed its initial experimental 100-kilowatt (kW) wind turbine at the center’s Plum Brook Station facility in 1975. The Mod-0 turbine was a two-bladed, horizontal turbine. By 1978, the 2-megawatt (MW) Mod-1, the world’s first multimegawatt wind turbine, was developed—capable of providing electricity to thousands of homes. Successive experimental models (thirteen in all) were built throughout the country. Viterna noted that these were also record setting in size and output; the 4 MW capability of the WTS-4 turbine, built in 1982 in Medicine Bow, Wyoming, was not surpassed for about twenty-five years.

“That’s how far ahead the program was in terms of developing this technology,” Viterna said.

NASA’s efforts led to other industry innovations that are standard today. As Glenn researchers explored ways of reducing the weight and cost of turbine structures, they developed steel tube towers that replaced the rigid truss towers traditionally used. “Today, virtually every large wind turbine uses a steel, tubular tower, which was novel technology at the time,” said Viterna.

For more than twenty years, NASA’s 4-megawatt WTS-4 wind turbine held the world record for maximum power output.

Photo courtesy NASA Spinoff

Despite the advances made by the NASA-led program, there were still significant challenges. “One of the key things then and now is to accurately predict the forces exerted on a wind turbine,” Viterna said. On a basic level, wind turbines use the same forces that allow airplanes and helicopters to fly. Wind blowing over the turbine’s blades, or airfoils, creates lift that turns the blades, spinning a shaft that connects to an electricity-producing generator. When engineers first began to model the impact of these forces on wind-turbine airfoils in high-wind conditions, they would produce results that were off by at least 50—and sometimes as much as 100—percent.

The problem was that wind turbines, unlike most other airfoil-based systems, operate at a high angle of attack—the angle formed between the chord of an airfoil and the direction of the airflow. (A chord is an imaginary line through an airfoil’s cross-section, joining the tip of the trailing edge to the center of the leading edge.) In airplanes, when the angle gets too large, the laminar air flow that typically hugs the wing begins to detach and become turbulent, reducing lift and increasing drag; at a certain point, the plane stalls and drops out of the sky. Wind turbines, especially in high-wind conditions, can routinely stall, limiting the ability of the turbine to produce electricity. The inability to properly predict stall behavior, actual aerodynamic loads, and the relationship between wind speed and power in wind turbines led to inefficient designs and costly failures. At the time, there was a significant lack of research and data in this area, Viterna explained, as well as “three-dimensional effects going on that we had no way of calculating or even measuring.”

In 1981, using data previously collected from an old Danish turbine, coupled with test data gathered by fellow NASA researcher Robert Corrigan from the Plum Brook turbine, Viterna developed a model that took into account three-dimensional effects and predicted stall behavior with far greater accuracy than previous methods.

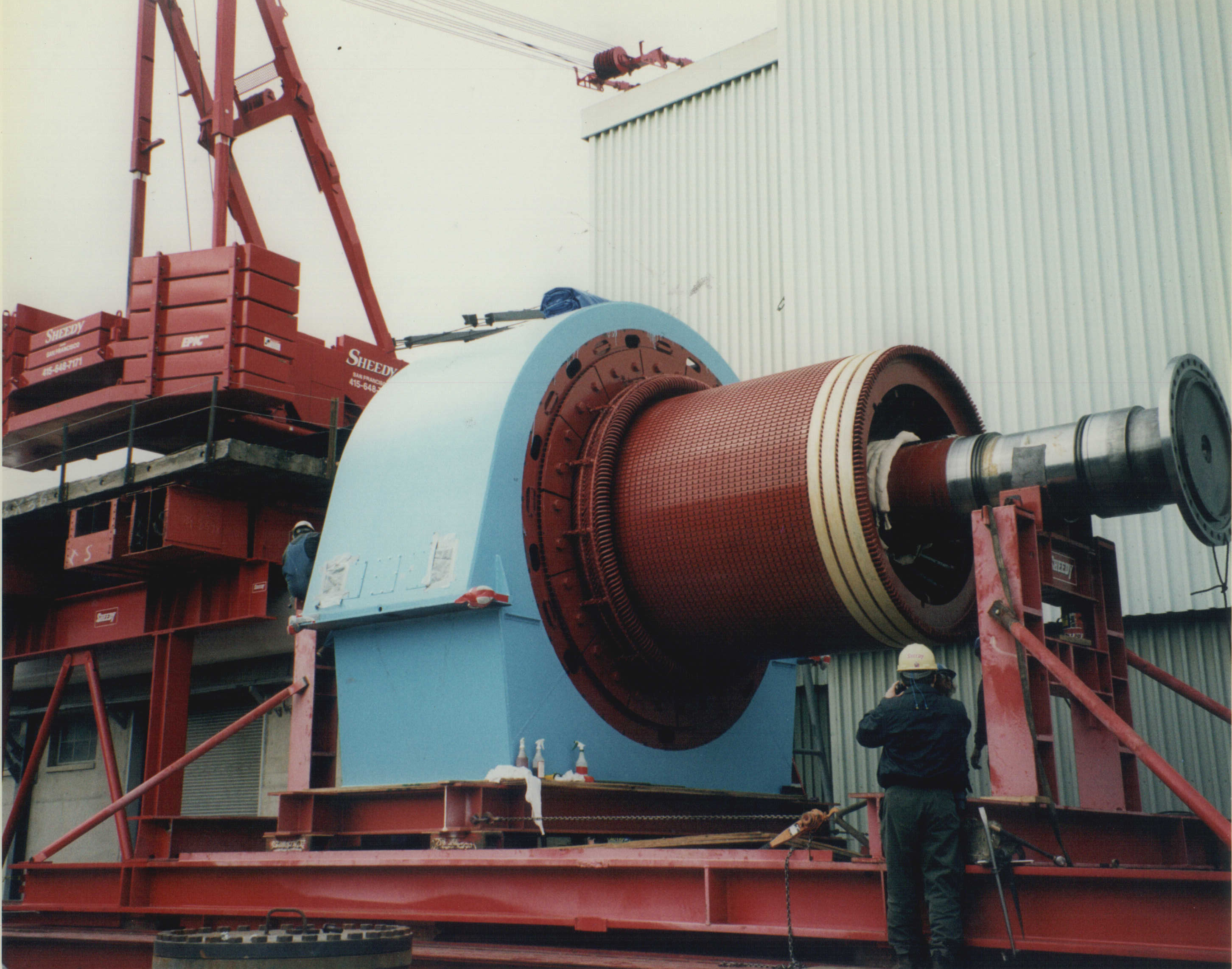

The model was not well accepted by colleagues in the wind-energy field, Viterna recalled. “I almost got laughed off the stage when I presented it,” he said, explaining that the model violated existing theories that used two-dimensional airfoil data. Viterna, however, continued to employ the model, even using it in 1991 to improve Glenn’s Icing Research Tunnel, designed to study the effects of ice buildup on aircraft. Based on the model’s results, Viterna suggested that slightly shaving down the wooden fan blades could boost the tunnel’s 299-mph capability. During a nighttime test, the wind tunnel’s pressure release door flew open, sending 400-mph winds ripping through the adjoining work area. (The tunnel’s new upper limit after implementing Viterna’s model: 430 mph.)

The surprise Viterna’s coworkers encountered the following morning was on par with what Viterna experienced during a random Internet search nearly twenty-five years after inventing his model. In 2005, long after the easing of the energy crisis and shift of the wind-energy program to the Department of Energy, Viterna, now in Glenn’s Office of Strategic Management, was searching the Internet when he began to come across multiple references to the “Viterna method” by experts in the wind-energy field. He discovered his initially criticized model had, within a decade of its creation, quietly become the established method of modeling the performance of wind-turbine airfoils under high angles of attack—stall conditions.

“It had become, and still is, the most widely used stall model in the United States,” said Viterna, who along with Corrigan recently received a “Space Act Award” from NASA’s Inventions and Contributions Board, as well as the Agency’s inaugural “Blue Marble Award” at its Environmental and Energy Conference.

Among the many who use the Viterna method is the Department of Energy’s National Renewable Energy Laboratory’s National Wind Technology Center (NWTC), located in Boulder, Colorado. In 2005, the center added the Viterna model to its design-code software suite for horizontal-axis wind turbines, the most popular variety of turbines in use today.

By shaving the Icing Research Tunnel’s wooden fan blades according to the results of Dr. Larry Viterna’s model, Glenn engineers boosted the tunnel’s top wind speed by more than 130 mph.

Photo courtesy NASA Spinoff

“Viterna’s model does a very effective job of estimating stall behavior on inboard sections of the blade and how it varies along the blade’s span,” said Dr. Sandy Butterfield, wind program chief engineer at the NWTC. “Even though it was invented in the 1980s, it remains a model used by engineers predicting performance and loads for wind turbines.”

The NWTC suite—which offers design and analysis software tools for use in achieving worldwide certification of wind turbines—incorporates Viterna’s model in its FoilCheck preprocessor. FoilCheck allows users to generate airfoil tables and compute dynamic stall parameters for use in NWTC’s AeroDyn software library, which enhances the center’s YawDyn, FAST, and ADAMS turbine simulators. The entire suite is available to private industry for free, which has enabled wind-turbine manufacturers like Westport, Massachusetts-based Aerostar Inc. to use Viterna’s method to help craft their products.

The Viterna method is finding applications beyond horizontal wind turbines; Viterna has discovered his once-mocked model is now employed for vertical wind turbines, wind tunnels, and even underwater turbines that make use of tidal energy to produce power. In the meantime, NASA continues to be involved in the advancement of wind energy; Glenn, for example, is supporting the plans of Cuyahoga County, Ohio, to establish on Lake Erie the world’s first freshwater, offshore wind-turbine site.

The agency can also expect to see its early work experience a resurgence, predicted Dr. Butterfield of the NWTC. “As the industry moves forward and becomes more competitive and broad, you will see efforts to explore lower-cost, more structurally efficient machines, and that’s when people will begin to capitalize again on that good work NASA did in the early 1970s and 1980s,” he said. It seems likely that Viterna’s and NASA’s pioneering work will continue to play a significant role, given the nation’s ambitious energy goals: the Department of Energy has outlined a plan for generating as much as 20 percent of the country’s energy from wind power by 2030.

This article was originally published in NASA’s Spinoff 2009.

About the Author

| Bo Schwerinis an award-winning author and works at the NASA Center for Aerospace Information as a senior science writer for NASA’s annual Spinoff publication. |