Bryan Fafaul, Glory Project Manager from Goddard Space Flight Center, talks about the launch of the GLORY mission during a news conference at NASA Headquarters, Thursday, Jan. 20, 2011, in Washington. Photo Credit: NASA

April 30, 2012 Vol. 5, Issue 4

The Glory mishap provides a lesson about balancing risks to make the best decision possible.

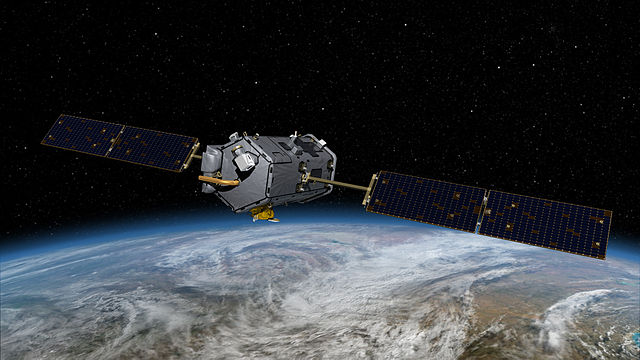

On March 4, 1999, project manager Bryan Fafaul saw the Wide-field Infrared Explorer (WIRE) primary mission slip away when the instrument cover prematurely ejected, causing the spacecraft to spin out of control and deplete all of its cryogen. Exactly twelve years later, Fafaul watched the Glory mission fail to reach orbit and plunge into the ocean.

Leading up to launch of Glory on March 4, 2011, the three main risks on the Glory project revolved around three pieces of hardware: the Advanced Polarimetry Sensor (APS), the Taurus XL launch vehicle, and the spacecraft bus. For Fafaul, the Glory project manager, getting to the launch pad meant having the right people working each issue and gathering the right data in order to mitigate the risk. Unfortunately for Glory, one of the three risks wasn’t sufficiently resolved. “You can’t recognize everything,” Fafaul said during a case study session on Glory at the Goddard Space Flight Center’s Masters Forum on April 24, 2012. “That can-do attitude sometimes results in a more optimistic assessment of closing out an issue than what reality will actually dictate to you.”

The APS instrument was designed to measure reflected light from aerosols in the atmosphere to help characterize their size, shape, and type, and determine their distribution within the atmosphere. The contractor responsible for building the APS instrument experienced significant delays, and just after the Critical Design Review, Fafaul was informed that the contractor facility would be closing and the work would be relocated. The move resulted in instrument workforce attrition (an initial team of 75 turned into 15, which became 3 in the end). This turn of events cost the Glory project nearly $100 million. “We never really struggled with the technical issues on APS. It was purely execution,” said Fafaul.

The most visible issue to work to ground was the launch vehicle. On February 28, 2009, a Taurus XL launch vehicle failed to place the Orbiting Carbon Observatory (OCO) into orbit. The vehicle fairing had not detached properly. Initially, Glory was scheduled to fly before OCO, but the delays with the APS instrument pushed their schedule back behind OCO. When OCO plunged into the ocean, Fafaul thought, “I’m not going to have the same problem because there will be enough time to fix it.”

The Advanced Polarimetry Sensor instrument inside the thermal vacuum chamber.Technicians wear garments — known as “bunny suits” — to protect the instrument from dust and other contaminants.

Photo Credit: Raytheon

Nearly two years after the OCO failure, the Mishap Investigation Board was unable to produce a root cause for why the launch vehicle had failed. The investigation produced a number of possible proximate causes—all of which were logically assessed and addressed—but the “smoking gun” was still at large. All eyes at NASA were on the data. The Glory project team worked closely with Headquarters and the Launch Services Program to gain insight into the launch vehicle return to flight activities. No one took a dissenting opinion that was strong enough to derail the decision to move forward with the launch.

The spacecraft bus also played a role in the decision to proceed with the launch. The bus was originally designed for the Vegetation Canopy Lidar (VCL) mission. After VCL was cancelled in 2000, the decision to use the bus on Glory meant refurbishing it to be flown in a different orbit, launched on a larger rocket, and able to withstand different conditions in space. The adaptation of the VCL bus for the mission invited in a different set of risks to the project, explained Fafaul. The team encountered a number of challenges with keeping the hardware alive and maintaining data and documentation, which were in danger of being eliminated due to seven-year data retention practices. Just over a decade old, the propulsion tank bladders on the bus were approaching end of life. Balancing out the risks, Fafaul determined that the risk of postponing the mission and grounding the spacecraft for two years could actually be a bigger risk than choosing to fly.

When asked what he would do if he were in the same situation all over again, Fafaul replied, “I would not have made a different decision. The decision was a fact-based decision. You make risk decisions every day as a project manager. Hopefully you make the good decisions off the data that you have.”

“There will always be the opportunity to get more information,” Fafaul added. “There’s a chance we could have spent two years on the ground and not found a problem.” Discussion about access to the detailed MIB report on the OCO failure brought to light the importance the people doing the work having the ability to learn from such reports. “I think there needs to be better access to them,” agreed Fafaul. “There needs to be more exposures of these MIBs back to the people who are going to learn from them. It’s closing that loop.”

Fafaul now has two pictures that hang across from his desk: one of WIRE and another of Glory. “I think that in every successful mission, you’re right on the edge,” said Fafaul. “We just happened to be on the wrong side of the line.”

Read about OCO from the perspectives of Ralph Basilio, OCO-2 project manager, and Patrick Guske, mission operations systems engineer.

Watch a video of Bryan Fafaul on the WIRE mission.

Bryan Fafaul, Glory Project Manager from Goddard Space Flight Center, talks about the launch of the GLORY mission during a news conference at NASA Headquarters, Thursday, Jan. 20, 2011, in Washington

Featured Photo Credit: NASA