In this photo from 2013, a welder at NASA’s Stennis Space Center works on a portion of piping to be installed on the A-1 Test Stand for RS-25 rocket engine testing.

Photo Credit: NASA/MSFC

Small Steps, Giant Leaps highlights crucial role in NASA missions.

In the summer of 2002, inspectors examining the liquid hydrogen supply system of the Space Shuttle Atlantis in advanced preparations for STS-112 found small cracks near a slotted region of a gimbal joint flow liner. Subsequent inspections found similar cracks in other shuttles. NASA thoroughly investigated the issue and devised a solution in which a team of highly skilled welders repaired the cracks and polished any imperfections.

“The NASA workforce is what makes this agency so special, and from my earliest days flying the Space Shuttle I’ve been amazed at the unbelievably important contributions technicians make to NASA missions,” NASA Deputy Administrator Pam Melroy said recently on the Small Steps, Giant Leaps podcast. Melroy was the Pilot of STS-112, her second spaceflight.

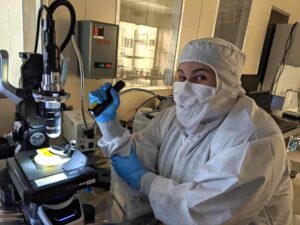

Jason Nelson works in the Experimental Fabrication Branch at NASA’s Armstrong Flight Research Center in California, as the lead of sheet metal welding, composite, and 3D printing.

Photo Credit: NASA/Lauren Hughes

“At NASA, our skilled technical workforce — our team of talented machinists, welders, sheet metal workers, and technicians — make the seemingly impossible, possible. To be a technician who works on NASA projects, you need unwavering attention to detail, a dedication to accuracy, and excellent problem-solving skills,” Melroy said, speaking in introductions to a recent three-part podcast series focusing on NASA’s tradespeople and technicians.

The concept for the series originated from a conversation between senior leaders at NASA, discussing the crucial role that tradespeople and technicians play in the success of NASA’s missions, according to Steve Angelillo, APPEL KS Deputy Director.

“We put together a strategy to highlight the wide variety of ways that trade and technical professionals support engineering on NASA missions,” Angelillo said. “After reaching out to some of our key stakeholders, we were excited to learn more about how these individuals support mission success. These talented individuals provide solutions in complex environments, creating tools, structures, or composites that support space exploration and science here on Earth.”

The first episode of the series was released on August 23. Podcast host Deana Nunley interviewed three engineering technicians at NASA’s Armstrong Flight Research Center in California. Alex Zamora works in the Experimental Fabrication Branch, in the machine shop. Jason Nelson also works in the Experimental Fabrication Branch, as the lead of sheet metal welding, composite, and 3D printing. And Kyle Whitfield is an engineering technician with a focus on welding and serves as a certified welding inspector.

“Right now, is the era of X-planes,” Zamora said. “In our shop we’ve touched on a lot of X-57, modifying electric motors, X-59, the Low Boom Flight Demonstrator. We’ve made many parts for that, some inlets on the aircraft to track airspeed, and then now there’s the X-66 Transonic Truss-Braced Wing. That’s a new project coming up that we’re going to be, I think, heavily involved in. So, a lot of fun work coming through the shop right now, a lot of cool things happening.”

Maria Salinas, an Engineering Technician working at NASA’s Langley Research Center, checks for contaminants.

Photo Credit: NASA

The second episode of the series was released on September 6, 2023. Nunley spoke with four technicians who specialize in everything from lasers to contamination control to additive manufacturing. Scott Bartram discussed his work as an Equipment Specialist in the Research Directorate at NASA’s Langley Research Center, providing support on aeronautics, acoustics, and space lens development to numerous projects. Eric Bentley discussed his work as an Engineering Technician in the Components and Hardware Branch at NASA’s Goddard Space Flight Center (GSFC), where he is responsible for creating fabrication drawings for project hardware. “…I’m a drafter. I’m the guy that makes the drawings that get sent out to fabricators and we have flight hardware and any type of hardware that you need for your project. That’s what I do,” said Bentley, who has worked at GSFC for about 30 years. “I create drawings or modify drawings, but it all depends on what projects I’m working on. I do mechanical drawings mostly. And I also started helping out the electrical side of the house and I do cable drawings and harnesses and things of that nature.”

Nunley discussed contamination control with Maria Salinas, an Engineering Technician working at NASA’s Langley Research Center. And Phil Steele discussed the additive manufacturing work of the Advanced Manufacturing Branch at NASA’s Marshall Space Flight Center.

John Hood, right, an Engineering Technician at NASA’s Marshall Space Flight Center, works on X-ray mirror replication and shell separation.

Photo Credit: NASA/Emmett Given

“It’s very satisfying and humbling to see the parts that we’ve produced be launched and used in space,” Steele said, noting that the International Space Station’s Environmental Control and Life Support System contains several parts produced with additive manufacturing. “What is most rewarding is [also] the most challenging, and that’s to keep up with the new developments, and materials and processes.”

The third episode of the series was released on September 20, 2023. Nunley spoke with three engineering technicians — John Hood, Amy Meekham, and Mark Sloan — who work at NASA’s Marshall Space Flight Center and supported areas that were essential for the success of the Imaging X-ray Polarimetry Explorer (IXPE) mission, an international collaboration between NASA and the Italian Space Agency.

The IXPE is a space observatory with three telescopes, each with a set of cylindrical mirrors that collect X-rays from celestial objects and focus them on sensitive detectors. These mirrors presented several challenges for the team.

“So, to start, as a team, we were tasked with making 96 X-ray telescope mirrors for IXPE. IXPE had four mirror modules and each module had 24 replicate shells that would go inside of it, and all 24 shells are different diameters, so they could be nested inside the largest shell,” Sloan said. “Before IXPE, I had never heard of an angstrom, but we were told they had to be polished to one to five angstroms and I don’t know if everyone else is like me, but that was just a crazy number to me. It’s equal to 100 millionth of a centimeter and used to express interatomic distances. That level of polishing makes for much better than mirror finish.”

The series has been popular with Small Steps, Giant Leaps listeners.

“I personally am hoping that through these episodes our audience gets to experience the professionalism, dedication, pride, and personal satisfaction these professionals bring every day contributing to NASA missions. It really is remarkable. Deana Nunley, our podcast moderator, did an outstanding job talking with our guests and helping them share their stories and experiences with our audience,” Angelillo said.