NASA’s design labs are where engineers develop concepts for missions and scientific instruments.

How does a mission idea go from paper napkin to launch? Where does it begin? You need a space where scientists, engineers, and project managers come together to bring ideas to life. NASA’s Goddard Space Flight Center in Maryland has one of these spaces and it’s called the Integrated Design Center.

It’s a collaborative, high-energy environment where mission concepts are born, refined, and then prepared for flight. From Earth-science instruments to deep space observatories, this is where innovation meets practical design. And the seeds of future missions are planted here as well.

In this episode, you’ll learn about:

- Taking missions from concept to reality

- Mission development cycles

- Advancements in automation and digital engineering

Liz Matson is the manager of NASA Goddard’s Integrated Design Center (IDC). She began her career as a structural analyst for several flight missions including: the James Webb Space Telescope, Lunar Reconnaissance Orbiter, and the Thermal Infrared Sensor (TIRS) on the Landsat-8 satellite. Prior to her current role, Matson served as the deputy instrument systems engineer for the L’Ralph instrument on the Lucy mission, was the lead mission systems engineer in Goddard’s Mission Design Lab, and supported multiple studies in the IDC’s Instrument Design Lab. She holds a bachelor’s degree in mechanical engineering from Case Western Reserve University and a master’s degree in aerospace engineering from the University of Maryland College Park.

Liz Matson is the manager of NASA Goddard’s Integrated Design Center (IDC). She began her career as a structural analyst for several flight missions including: the James Webb Space Telescope, Lunar Reconnaissance Orbiter, and the Thermal Infrared Sensor (TIRS) on the Landsat-8 satellite. Prior to her current role, Matson served as the deputy instrument systems engineer for the L’Ralph instrument on the Lucy mission, was the lead mission systems engineer in Goddard’s Mission Design Lab, and supported multiple studies in the IDC’s Instrument Design Lab. She holds a bachelor’s degree in mechanical engineering from Case Western Reserve University and a master’s degree in aerospace engineering from the University of Maryland College Park.

Resources

Mission Design Lab

Instrument Design Lab

Integrated Design Center

NASA Internships

Courses

APPEL Virtual PM Challenge (On Demand)

Communicating Technical Issues (APPEL-vCTI)

Foundations of Aerospace at NASA (APPEL-vFOU)

Transcript

Andres Almeida (Host): Welcome to Small Steps, Giant Leaps, your NASA APPEL Knowledge Services podcast. In each episode, we dive into the lessons learned and real-life experiences of NASA’s technical workforce. I’m your host, Andres Almeida.

How does a mission idea go from paper napkin to launch? Where does it begin? You need a space where scientists, engineers, and project managers come together to bring ideas to life. NASA’s Goddard Space Flight Center in Maryland has one of these spaces and it’s called the Integrated Design Center.

It’s a collaborative, high-energy environment where mission concepts are born, refined, and then prepared for flight. From Earth-science instruments to deep space observatories, this is where innovation meets practical design. And the seeds of future missions are planted here as well.

In this episode, we’re stepping inside the IDC with manager Liz Matson to learn how multidisciplinary teams work side by side to develop complex systems, tackle tough engineering challenges, and turn visionary concepts into launch ready realities.

Andres Almeida (Host): Hey, Liz, thanks for joining us.

Liz Matson: Yeah, sure! Thanks for having me.

Host: So, can you give us an overview of the Integrated Design Center and its role in shaping NASA space missions?

Matson: Sure. So, the Integrated Design Center, we call it the IDC, is a multi-disciplinary concurrent engineering facility that specializes in early concept mission and instrument design.

That really just means we have a whole bunch of engineers working in one room at the same place to start a concept of something very cool, whether it’s something from a napkin sketch, or a little bit more advanced. And we do that in one of our two labs.

We have the Mission Design Lab, which, as you can imagine, works on missions and focuses on spacecraft, and then our Instrument Design Lab. So, in the MDL, we work on conceptual designs for missions that range from Earth orbiting spacecraft to deep space and planetary probes. And then the Instrument Design Lab develops concepts for instruments like Lidar and mass spectrometers. So, our goal is really to connect our scientists and tech development folks with our systems engineers from an early place, so we can do early risk assessments, trade space exploration, put some, some technical meat behind a lot of these concepts.

Host: So, when a new mission concept comes into the MDL, what’s the first step in that design process? And how do you go from an idea to a, let’s say, a preliminary mission architecture?

Matson: Yeah, so the first step is understanding where the mission is in their development process. Is it a napkin sketch? Have they already put some engineering work into it? That helps us figure out if our role is trying to prove that this design is even feasible, or if we’re there to more explore the trade space, find a design solution that really optimizes the science they’re trying to do in often the cost box they’re trying to fit in. Or if we’re working to baseline a design that they’re, you know, closer to actually building.

So, then our systems engineers work with the customer team (and usually our customer is a scientist or a project manager) to really understand the requirements for their mission or their instrument. And then our systems engineers spend some time translating those requirements into the technical information that the discipline engineers need to flesh out the design – and that’s when the magic happens.

So, once we start our study, we are together for usually about a week. We have about 10, 10-ish subject matter experts in the MDL. That’s typically mechanical, flight dynamics, propulsion, avionics, power, attitude control. And our team lead facilitates this, you know, design burst for about a week – usually, you know, five, six days, working together – so that at the beginning of the week, we’re just trying to get on the same page and understand the requirements and what we’re trying to do. And then at the end of the week, we’re presenting a fleshed-out design concept. Still very preliminary, but, you know, a design that is feasible.

Host: It sounds like not a long time, but I’m sure it’s just a very comprehensive sort of process in the beginning, huh?

Matson: A week is not a long time, but you would really be surprised in how much work you can get done when everyone is in the same space, you know, for eight hours a day, for a week straight. You’re talking to each other. There’s no emails and then waiting for answers. You just walk over to the person or raise your hand. And then, typically, we have a “Wednesday surprise” where someone raises their hand, says, “Oh, I found something that doesn’t work!”

And then, you know, everyone spends the day scrambling to see how that impacts their design, so that, the ripple effects of how that works and how, you know, the team pulls together to, you know, make trades and figure out different things to make the design work. That’s, that’s really fun. But yes, it’s, it can be intense. We are fueled by pastries and coffee.

But we’re, we’re, I just, I really enjoy working with all these folks. They’re very talented, and we have a good time.

Host: So, I imagine there’s so many engineering challenges that come up in this process and throughout the whole process, right? But what are some common engineering challenges that you encounter in this phase?

Matson: You know, honestly, I think our biggest challenges are less technical and more communication. And we structure, we’re structured how we are to try to combat those communication challenges where someone says, “Oh, I have a problem, and, you know, this affects everybody else in the room, so, so we need to talk about it.” I think often in what we do – I don’t know that it’s a secret – we solve technical problems, right? But the people part, and the communication and making sure everyone is on the same page and communicating well is, I think, in general, sometimes harder to solve than the technical problems. And I do think the way that we’re structured helps break down a lot of those barriers.

Host: Would you mind sharing an example of a mission that went through the IDC and how its final design evolved over time?

Matson: Yeah. It’s important, I think, to mention that the IDC is so early in the development process that we usually see things at least 10 years before they launch. So, one thing that launched recently, PACE, the Plankton, Aerosol, Cloud and ocean Ecosystem mission, that launched back in 2023, the first time our lab touched one of the concepts was actually for a prototype for the Ocean Color Instrument [OCI] back in 2009. So, this was a prototype, land-based prototype. It wasn’t going to fly. It was very large, but it was in our lab in another building at Goddard.

So, we looked at a study for that prototype, and then they came back for more studies in 2012 and then 2015 before PACE passed their mission concept review in 2016, so that was a pretty big process. But I think it’s important to know that when the design changes, it’s always for a good reason, and that reason is typically a requirement change, or, you know, some part of the design process where there was a ripple effect and they have to, you know, solve something over here to make something over here work.

And OCI itself, I think going from the lab unit, which was very heavy, size-wise, wasn’t going to be able to fly. Just trying to repackage that for a satellite was a, was a big challenge. So we were, it was before my time, but the IDL and MDL, also on the PACE spacecraft side, had a number of studies, and we were thrilled to see that launch.

Host: How does the Mission Design Lab and Instrument Design Lab approach interdisciplinary collaboration to ensure feasibility of a mission?

Matson: Yeah, so that it’s that real time collaboration. That’s exactly why we’re organized how we are, so everybody in the room at the same time, we can make sure we’re on the same page, check our assumptions. We build that into our processes in how we do daily stand ups, check-ins, how we document decisions, assumptions.

We recognize some people hear things in different ways, right? So, we want to make sure we have something in writing. We want to make sure, you know, it’s said out loud for the auditory learners. And our systems engineers are really great at block diagrams. I think just the magic of color-coding [laughter] block diagram, just so people can see whether it’s a, you know, we’re talking about it. Where the light goes in, you know, for a telescope, or, you know, data flow, or just thermal zone. The IDL and MDL, both are structured very similarly. We have, just have different folks in the room.

So, I mentioned in the MDL, it’s, you know, spacecraft-focused propulsion, attitude control and things like that. The IDL has a different group of people depending on what instrument they’re working on. So, you know, obviously we’ll get laser experts for a laser, microwave experts for radar. One of the challenges, I think in the IDL, is that it’s a different set of questions every time, and a little bit different data flow depending on what flavor of instrument we’re working on that week.

Host: I picked up that all these teams try to work together empathetically, meaning different learning styles, trying to…

Matson: Yeah.

Host: …make sure that communication is clear. Do you see that?

Matson: Yeah, I don’t know that we do it on purpose, but, you know, our team leads are purposefully very good communicators and just making sure that everyone in the room is, you know, able to participate in understanding. Communication is really key.

And we’re bringing people from such different backgrounds, you know, people who have only worked implementation, right? So, they’re in INT and focused. And so, it’s a very different framework, thinking about that versus drawing on a whiteboard. And, you know, it’s the, “Okay, well, this was the 1:32 p.m. design. Now we’ve moved on to the 3:37 p.m. design.” You know, things evolve quickly. And it’s, you know, it’s a different skill set.

So, I think, you know, part of our communication process is, you know, making sure people are comfortable, people understand rules of engagement, right? That, “Don’t tell me it’s you know, 32.37 degrees. I care if we got the ‘30’ part,” right? You know, that’s where we are, and it’s a really different mindset shift.

But we love, you know, it’s a different group of people each study on purpose, because people bring different mission and instrument background and experience. And it’s just, it’s great to have that mix. At the same time, we are building a new team every study we do. And there’s some, I don’t want to say growing pains, but you know, just learning people and learning how they work.

Host: Yeah. There’s always growth.

Matson: Yeah, for sure.

Host: What can you say about the increase of automation and digital engineering? How are these technologies kind of shaping the way missions are designed?

Matson: Yeah, there’s so much potential for automation and to streamline our processes, especially what we do working, you know, we have a lot of processes that repeat every week. Even though we’re doing a different mission or a different instrument, our processes are very similar.

So, you know, one of the things, I work very closely with Aaron Comis, ETD’s Chief Digital engineer, because I do think the IDC is a perfect proving ground for digital engineering advancement, because we can, you know, try something in this week, take some lessons learned, see what works, see what doesn’t, and, you know, try it again for the next study. So, I’m really excited about things we’re trying to do and what we’re learning.

So, one of the things we’re trying to do right now is improve how our different engineering tools communicate and share data. So, we’re working to develop an orchestration tool that streamlines how the different disciplines, their tools, communicate to each other. So, it streamlines the interdisciplinary flow (a digital thread, if you will) and establishes a single source of truth.

And it’s that single source of truth in the model, or, you know, whatever it will look like in this orchestration tool that really is our is our touchpoint throughout the week, so that everyone is on the same page.

So, I’m really excited about automating that process and how our tools talk to each other. There’s obviously also a lot of potential to automate, you know, and do some AI work.

We have 28 years of archives, you know, design archives. You know, I am talking with folks on trying to figure out how to build a tool to data mine those archives so we can have lessons learned and we’re not starting from scratch for every concept.

Host: So, looking ahead, what kinds of future mission concepts are exciting to you, and what emerging trends in spacecraft or instrument design could revolutionize space exploration.

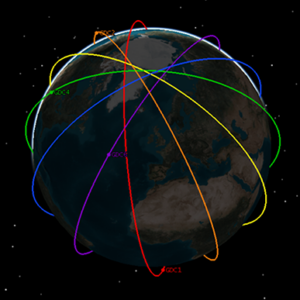

Matson: So, I’m really excited about the potential for using intelligent networks and distributed missions. There’s so much, and I’m thinking space weather, but you know, Earth observations and many different things, where just establishing that a larger network, where you have, you know, time and space, and it’s a larger distributed mission, but maybe they’re smaller distributed right?

So, you can get things up, you know, faster and more efficiently. I’m excited about the potential for that, and the MDL specifically, I think we’re well-equipped to look at what those swarms, you know, or constellations of missions would look like.

Host: Do you also collaborate or share knowledge with the other mission design labs across the agency?

Matson: Yeah, so, we have a Teams chat. There are there a few of us. So, I talk to the folks at Langley, I think the most often, and COMPASS at Glenn. You know, with the Ames lab and our lab we’re probably the most similar. And then, of course, JPL has their Team A and Team X.

So, it’s hard because we’re distributed. You know, time zones and geography. But yeah, we had an opportunity to all meet each other at a conference a couple years ago. Then, again, presented a group of us about our respective design labs at last year’s systems engineering seminar that Glenn hosted.

So yeah, so we try to keep the chat going and lessons learned. But yeah, if they’d all like to, like to visit, I’d love to host.

Host: One final question for you. Liz. What was your giant leap?

Matson: So, I won’t say how long I’ve been here [laughter], but I will, but I will say I started out as a structural analyst in the mechanical engineering division. I was doing that for about 15 years before I moved to systems engineering. And I loved it.

We did bypass acoustic testing. I was literally in charge of, you know, nuts and bolts and, you know, picking out, okay, how many number 4 fasteners need to go on this fixture? And I really enjoyed it. But my favorite part of it was coordinating STOP analysis, that stands for Structural Thermal Optical Performance – STOP. And what you’re doing with that work is really coordinating analysis from thermal [engineers] and then to me as the structural analyst, and then the optical folks to systems in performance. And I really enjoyed that it was small, you know, very small, just three people. So, I wanted to do that on a larger scale.

And that’s what drew me to systems engineering, the multi-disciplinary coordinating and communication, right? That’s been a theme here, I think. And then, you know, one of my very first meetings as a systems engineer, when we’re talking about requirements, and, you know, talking to a scientist. And he’s super focused on Jupiter and his level zero requirements, and it was just such a huge leap for me talking about, you know, number 8 fasteners, and then, and then jumping to, you know, really the big picture, right? And talking about planets and the amazing science that our folks do here.

So, that was, that was my giant leap. And I’m, you know, still, the most fun I have is when I’m in the room with scientists excited about their concepts and figuring out how the IDC can help them.

Host: Excellent. Well, thank you so much. Liz, this has been wonderful. Thanks for your time.

Matson: Yeah, thank you very much.

Host: That’s it for this episode of Small Steps, Giant Leaps. For more on Liz Matson and the topics we discussed today, visit our resource page at appel.nasa.gov. That’s A-P-P-E-L dot nasa dot gov. Don’t forget, we also have other podcasts like Houston, We Have a Podcast, Curious Universe and Universo Curioso de la NASA. As always, thanks for listening.

Outro: Three. Two. One. This is an official NASA podcast.