By Scott Tibbitts

This story begins with a bit of serendipity: I was on a trip to see a Shuttle launch and I happened to sit next to a guy who was in charge of batteries for Space Systems/Loral. He told me that they needed to create a new battery bypass switch, the device that takes a battery out of commission if it goes bad.

After discussing the conversation back at my company, we decided that we could create the switch. We contacted the folks at Loral and they said, “Okay, let’s see what you can come up with. We need it as small as possible.” We asked, “How small?” They said, “We need it as small as you can possibly make it.”

I called in my lead design engineer and said, “Dave, I need you to make this switch as small as humanly possible.”

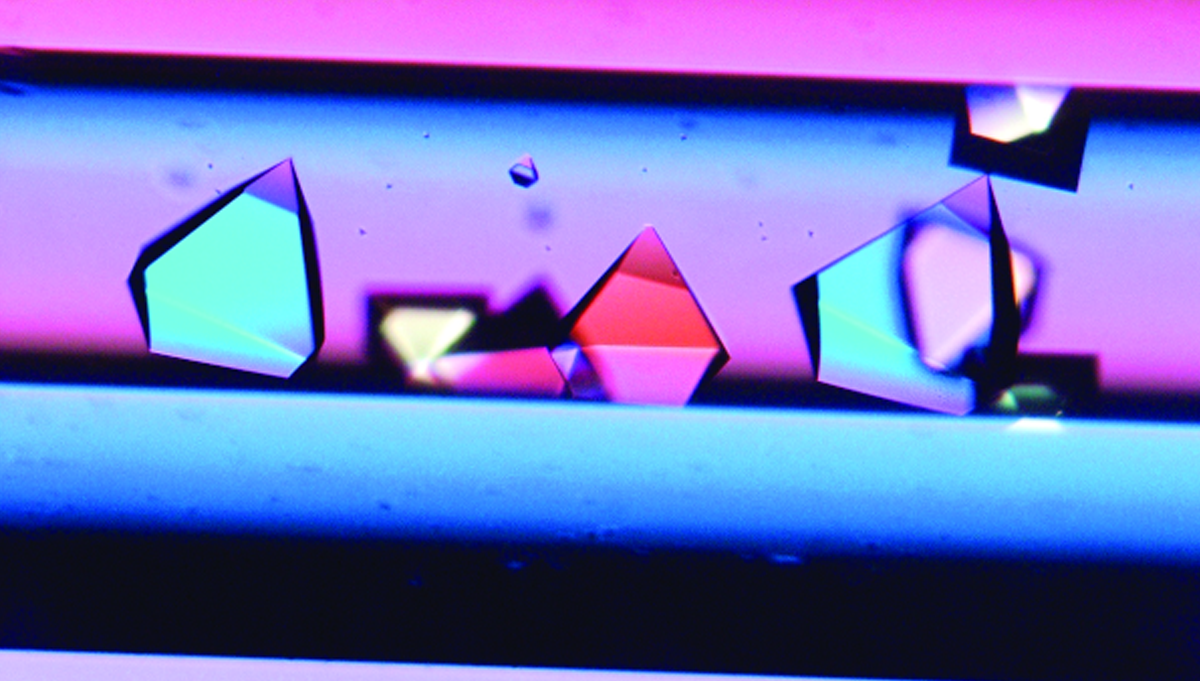

Dave went to work and he created a prototype for the bypass switch that we were pleased with. We showed the prototype to the customer and we said, “This is the smallest bypass switch we can make.” And they asked, “Are you sure?” And we said, “Yes, that’s it.” They told us that they weren’t too happy about the size, but if that was as small as we could make it, they would consider it.

this one was less than half the size of the new prototype.

A month later, we went to a trade show and saw a prototype for the same switch that a competitor had created. It was half the size of ours. I brought Dave over to take a look. We looked and looked at it. A week later, Dave came to me with a new prototype—this one was less than half the size of his first prototype.

Now, I can’t tell you how many times I harped on Dave before he designed the first prototype that it had to be “as small as possible.” But it wasn’t until he saw the dimensions of what someone else had come up with that he created his second, smaller design. One thing going on was personal pride: If another designer could do something, then, by God, Dave could do it.

I’ve come to call this “harnessing the power of the sun.” You don’t want to use this in a manipulative way, but if you have the opportunity to take someone who has a self-righteous pride that they can do something, couple it with talent and point them in the right direction, magic can come from that.

Another lesson that I’ve learned is that whether you’re talking to a designer about a prototype or to a team about an entire project, good managers don’t say, “I need it as small as possible,” or “I need it as inexpensive as possible,” or “I need it as soon as possible.” They set an ambitious but realistic goal, and they drive their team to it by saying, “Hey, I need this. How can we do it?” That’s when the creativity kicks in and people start thinking outside the box.

When you’ve agreed on such a goal, it’s amazing sometimes how clever people can get.

Lessons

- Setting ambitious but realistic goals for a project is a key to succeeding in today’s competitive environment.

- Competition is a powerful motivator—as is personal pride—which project managers may use to elicit creative contributions from individuals.

Question

When setting a goal for a project, how do you know whether it is ambitious enough?