By Colin Angle

Maybe an employee comes up with that brilliant idea for a new product. Or perhaps a customer makes a great improvement suggestion. Is Software Broken? Plus, you always have to keep your eye on the groundbreaking research and development (R&D) taking place in business, academia, and elsewhere. That’s the perpetual challenge: you never know where innovation is going to come from, which is why you need to look for it everywhere.

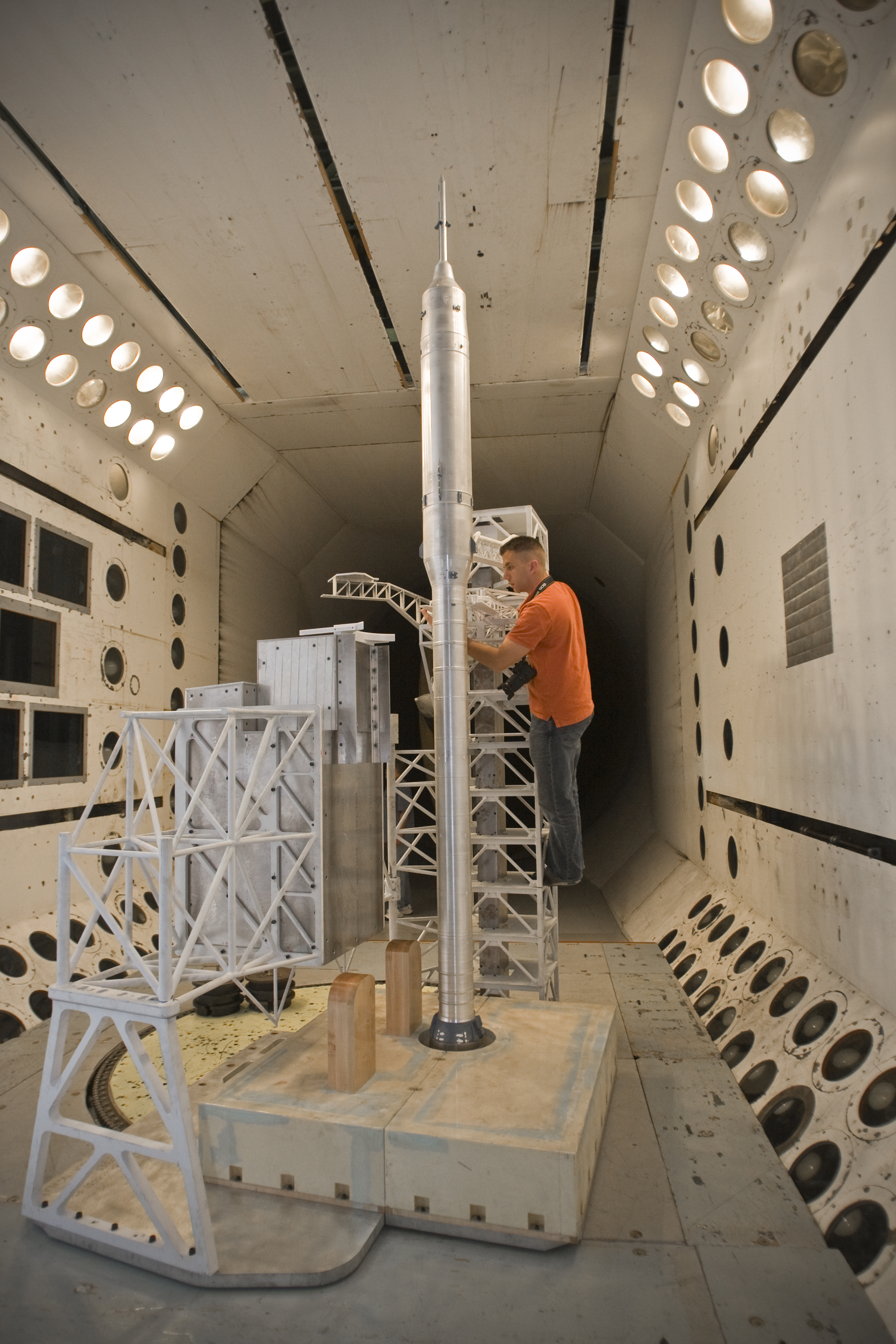

Industry partnerships are one way to develop new products that may never make it to market otherwise. One example is the iRobot PackBot with ICx Fido Explosives Detection Kit. iRobot teamed with ICx Technologies to integrate its explosive-detection technology into the combat-proven PackBot platform.

Photo courtesy iRobot Corporation

At iRobot, talented people and continuous communication are the cornerstones of innovation. We hire the smartest, most curious, and very creative people and communicate with them continually. Regularly scheduled all-hands meetings, just one of the companywide communication efforts, help everyone know about the projects being tackled by the other divisions. This basic but critical communication has stimulated a tremendous amount of cross-fertilization. For example, mine-hunting algorithms developed for our government and industrial robots were used by our home robots division for the iRobot Roomba floor-vacuuming robot. Likewise, the tracks on the iRobot Looj gutter-cleaning robot were derived from the iRobot PackBot tactical mobile robot.

But building a solid foundation is only the beginning. Whether it’s improving existing products or developing new ones, you have to dig, poke, and prod to keep innovation alive.

Looking Within

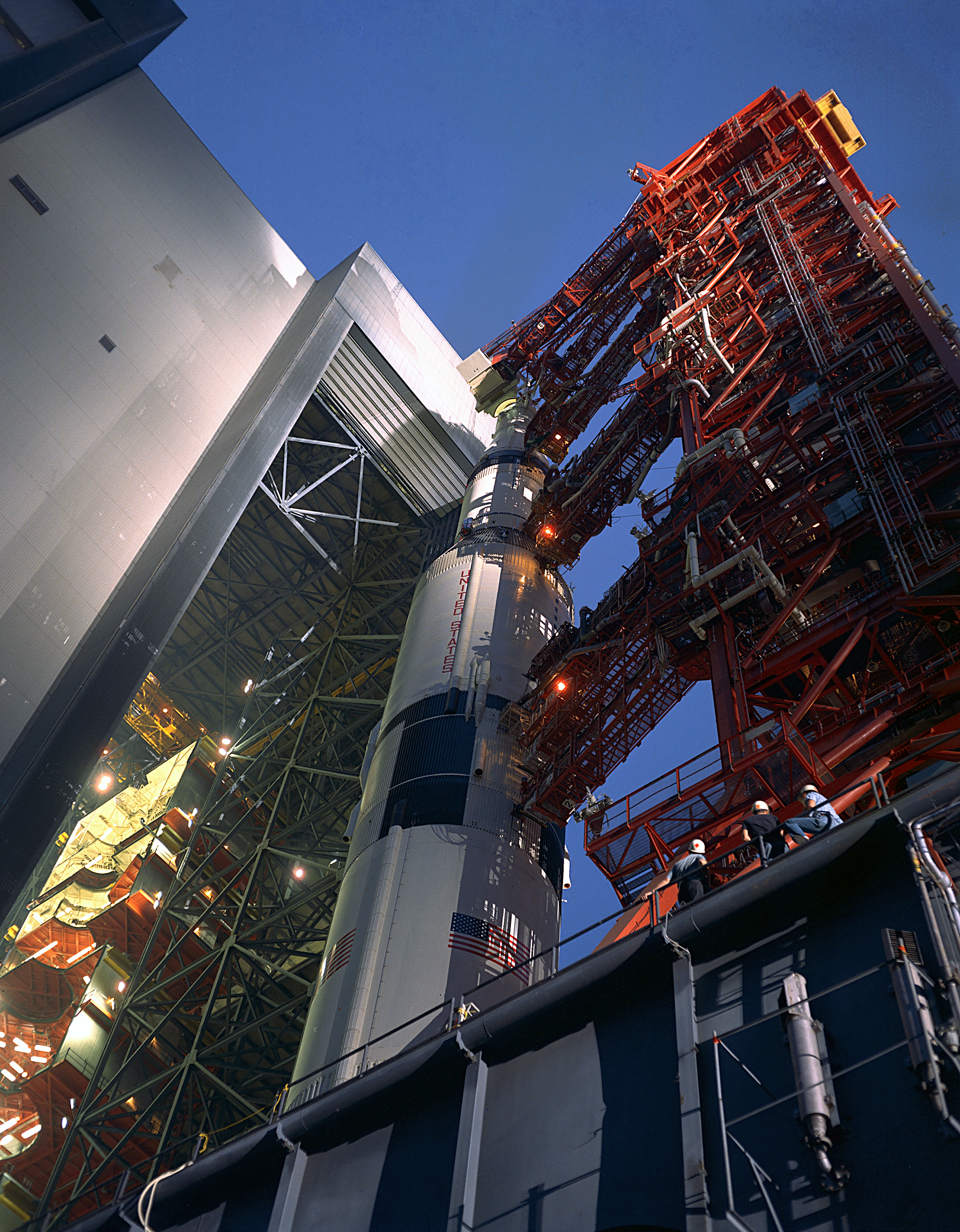

iRobot’s willingness to listen to employees and support their ideas has been central to our innovative core. In fact, the idea for Roomba came from a group of employees who thought an easy-to- use home-cleaning robot could make a difference in people’s lives. The employees were given two weeks and $10,000 to develop the concept—a collaboration that ultimately led to the world’s first affordable vacuum-cleaning robot. Roomba made practical home robots a reality for the first time and showed the world that robots are here to stay.

Today, more than three million Roomba robots have been sold worldwide. Roomba is not the only example. Looj is the result of an internal design contest; an employee made a crude prototype using a couple of motors and a bottle brush. Looj was rolling off the assembly line and into homes just nine months later. Similar internal exercises in our government and industrial robots division have led to a host of interesting capabilities for our military robots, including autonomous stair climbing.

Internal R&D has also been essential to the innovations brought to market by iRobot throughout the company’s nearly twenty-year history. With internal R&D, you always have to keep an open mind, and you always have to keep pushing yourself. One way to do this is by responding to government requests for proposals (RFPs) with requirements that are so far off the beaten track that they seem almost silly. But they force you to think in different ways and often result in success.

One of those recent successes for iRobot started with a government RFP to develop a soft, flexible, mobile robot that can maneuver through openings smaller than its actual structural dimensions—not something that comes across your desk every day. We responded and have been awarded a multiyear, multimillion dollar R&D project from the Defense Advanced Research Projects Agency (DARPA) and the U.S. Army Research Office to develop chemical robots called ChemBots. iRobot will lead a team of leading technical experts from Harvard University and the Massachusetts Institute of Technology to incorporate advances in chemistry, materials science, actuator technologies, electronics, sensors, and fabrication techniques.

Through this ChemBots program, robots that reconstitute size, shape, and functionality after traversal through complex environments—the stuff of science fiction—will become real tools for soldiers. ChemBots will be a revolutionary new robot platform that will expand the capabilities of robots in urban search and rescue, as well as on reconnaissance missions.

iRobot’s internal R&D efforts have helped establish our position as the leader in innovative robotics research and development. This didn’t happen overnight; in the past decade, iRobot has won a series of DARPA project awards. DARPA initially approached iRobot in 1998 to develop a robot for its Tactical Mobile Robot (TMR) program. DARPA requested white papers for a rugged, reliable, man-packable robot that could climb stairs and be used in urban combat. The other invited organizations wrote papers outlining their thoughts on urban combat robots. Only iRobot submitted a working robot prototype—along with the white paper.

The first TMR units were deployed on September 11, 2001, at the World Trade Center for on-scene investigation. Units were also deployed in Afghanistan, where they assisted frontline troops in searching enemy tunnel and cave complexes. TMR demonstrated iRobot’s technical capabilities to design, develop, prototype, test, and field a combat-deployable robot with advanced sensor capabilities. The follow-on contract from DARPA led to the creation of the iRobot PackBot, one of the most successful battle-tested robots in the world. PackBot is a multimission tactical mobile robot that performs search, reconnaissance, bomb disposal, and other dangerous missions while keeping warfighters and first responders out of harm’s way. More than 2,000 PackBot robots have been delivered to military and civil defense forces worldwide.

Over the years, iRobot has earned a reputation for rapid response and innovative thinking, deploying high-quality solutions in the shortest time possible. One of the most valuable lessons we’ve learned is to listen to our customers, both military and consumer.

Many of the very best ideas come from talking with users; we are constantly finding ways to reach out to them, to understand what they like about our robots, and to find out what other kinds of tasks they’d like our robots to perform.

The iRobot PackBot 510 with EOD Kit, a second-generation explosive ordnance disposal (EOD) robot, was designed specifically to address evolving end-user requirements for a stronger, faster, and easier-to-use robot. The robot is 30 percent faster, drags larger objects, lifts twice the weight, and has a grip that is three times stronger than its predecessor. One of the coolest innovations is the robot’s new hand controller. Modeled after video-game controllers, it makes PackBot 510 much easier and more intuitive to operate, resulting in less training time and more rapid and effective operations in the field.

In our home robots division, listening to customer suggestions has resulted in numerous product improvements and even the development of a successful new product. After the introduction of Roomba, we were often asked for a robot that could take on the laborious task of mopping floors. In response, we developed the iRobot Scooba floor-washing robot. Scooba built on our knowledge of floor cleaning but required new expertise in wet cleaning, fluid dynamics, locomotion in a wet environment, and other challenges. Scooba’s innovative technology uses a four-stage cleaning system to prep, wash, scrub, and squeegee a variety of hard floor surfaces. Unlike mop and bucket cleaning, Scooba uses only clean solution to wash floors, never dirty water. Scooba is a perfect example of an innovation that resulted from customer suggestions and by building upon a previous breakthrough.

Going Outside

While internal efforts are crucial, you also can’t lose sight of the important R&D going on in other companies, research labs, and universities around the world. You also need to know when to seize opportunities; iRobot recently leveraged external R&D done by two separate entities to advance the use and capabilities of Unmanned Underwater Vehicles (UUVs) and bring those innovations to the marketplace.

iRobot recently entered into a sole licensing agreement with the University of Washington to commercialize Seaglider a long-range, high-endurance UUV that makes oceanographic measurements. A deep-diving UUV, Seaglider is designed for missions lasting many months and covering thousands of miles. With Seaglider, civilian, academic, and military personnel can make oceanographic measurements, perform persistent surveillance, and accomplish other missions for a fraction of the costs of traditional vessels and instruments.

The idea for the iRobot Roomba vacuum-cleaning robot came from company employees who thought an easy-to-use home-cleaning robot could make a difference in people’s lives. The employees were given two weeks and $10,000 to develop the concept—a collaboration that ultimately led to the world’s first affordable vacuum-cleaning robot.

Photo courtesy iRobot Corporation

To accelerate iRobot’s strategic push into maritime systems, we also recently acquired Nekton Research, an unmanned underwater robot and technology company based in Raleigh- Durham, N.C. Over the next year, iRobot’s newly established Maritime Programs office in that location will focus on turning the Ranger prototype, a general development platform for small UUV capabilities, into a product. The licensing agreement and the acquisition have both helped to ensure that these innovations will eventually be available to customers who need robots to conquer new underwater frontiers.

Forming industry partnerships is another effective way to develop new products that may never make it to market otherwise. One example is the iRobot PackBot with ICx Fido Explosives Detection Kit. iRobot teamed with ICx Technologies to integrate its explosive-detection technology into the combat-proven PackBot platform. The robot can detect explosive vapors emanating from Improvised Explosive Devices (IEDs). PackBot’s dexterous, seven-foot arm allows the robot to place the explosive sensor close to suspicious packages and other objects, as well as reach through car windows and under vehicles. PackBot can also use its onboard capabilities to destroy IEDs, while warfighters remain out of harm’s way.

We were able to quickly test the robot in the field, get feedback, and refine the product based on user requirements. PackBot’s digital, modular architecture enabled fast and easy integration of the Fido payload, enabling our troops on the battlefield to quickly benefit from the new innovation.

The partnership has resulted in the first major deployment of explosives-detection robots and also demonstrates a new market application for robots. More than 100 of the explosive-detection robots have been ordered for use by the U.S. military in Iraq. This is an exciting and promising development; there is a growing need for robots that can safely detect and disrupt explosives, not just for warfighters deployed in the Middle East, but also for first responders around the world.

Ideas Everywhere

There is no one source for new ideas and no single way to innovate. Our experience at iRobot shows the range of approaches innovative organizations can and must embrace: listen to your employees and customers; tap into R&D; forge partnerships. Ideas for innovations are lurking everywhere; it’s your job to look high and low for them.

About the Author

|

Colin Angle is the chairman, CEO, and co-founder of iRobot. |