By Jason Crusan, Marybeth Edeen, Kevin Grohs, and Darren Samplatsky

What began as conversations between NASA and Hamilton Sundstrand managers grew into an idea to develop a piece of spaceflight hardware with minimal NASA oversight.  We expected this approach would allow the contractor to build hardware faster and cheaper while providing higher profit than the conventional cost-plus-fee contracting approach. In exchange for this free rein during development, the contractor would take on significant financial and technical risk throughout design, testing, and the hardware’s operational life cycle. The idea came to fruition with the Sabatier system.

We expected this approach would allow the contractor to build hardware faster and cheaper while providing higher profit than the conventional cost-plus-fee contracting approach. In exchange for this free rein during development, the contractor would take on significant financial and technical risk throughout design, testing, and the hardware’s operational life cycle. The idea came to fruition with the Sabatier system.

The system catalyzes the reaction between carbon dioxide and hydrogen— byproducts of current life-support systems onboard the International Space Station (ISS)—to produce water and methane. In exchange for Hamilton Sundstrand conducting and financing the design, development, testing, and evaluation of the Sabatier system, NASA would pay for its capability to produce water on orbit. If the system failed due to Sabatier-related hardware or software issues, then NASA would not be responsible for any payments to the contractor. In effect, NASA would pay for the availability of water production while the contractor would be responsible for maintaining system operability during the contract period. Holding Hamilton Sundstrand accountable for success significantly reduced NASA’s technical, cost, and schedule risks.

The water produced by Sabatier will be useful when we reach the end of the Space Shuttle program and the “free” water the shuttle has been providing as a byproduct of its fuel cells. But the Sabatier hardware will not be a critical ISS system, since future plans include water delivery by other resupply vehicles.

While it seems odd to build a system for manned spaceflight that does not have to work, this was the key to developing and executing our idea for the service-contract model: it allowed failure to be an option. At the same time, the risk of failure was relatively low since the existing technology needed for development was mature.

NASA and Hamilton Sundstrand had been researching Sabatier systems for more than twenty years. The contractor also had significant hardware-development experience and had developed the oxygen-generation system that interacts directly with the Sabatier system to provide hydrogen. In addition, the interfacing systems for the Sabatier were already in place and operational onboard the ISS. Since the Sabatier was always planned as part of the regenerative environmental control and life-support system on the station, the interfacing systems were ready for it.

Communication and Teamwork

After departing the International Space Station, the STS-130 crew onboard Space Shuttle Endeavour captured this view of the space station high above Earth.

Photo Credit: NASA

To increase our chance of success, we had open and honest communication between the organizations that allowed us to understand each other’s goals and challenges clearly. Frank communication began during initial contract negotiations, when it became apparent that without both parties being completely up front about their expectations, it would be impossible to close the deal. This meant each side had to explain its ultimate negotiating objectives and constraints in order for discussions to reach a mutually acceptable middle ground. Otherwise, significant differences that needed to be reconciled would have made it impossible to come to any agreement.

With an understanding of what was driving NASA and Hamilton Sundstrand requirements, we were able to define an approach to provide milestone payments before activation that were subject to a 100-percent refund to NASA if the hardware did not work upon on-orbit activation. This met NASA’s need to keep Hamilton Sundstrand’s “skin in the game” until activation and met Hamilton Sundstrand’s need for income during the development phase; it was referred to as a 100-percent look-back clause. While being open and honest about the real drivers behind our negotiation strategies went against our bargaining instincts, it enabled us to work together more efficiently toward a common goal: a mutually acceptable agreement that ultimately met all parties’ objectives.

We also had unwavering team commitment within both organizations, which allowed us to work through unexpected difficulties that arose as new contracting approaches were generated and implemented. Some of these issues were simple on the surface, and some were very complex. In one case, Hamilton Sundstrand provided a data product that met contract requirements, but because NASA did not sufficiently define the requirement for its format, the data could not be added to the relevant NASA database. To correct this, both NASA and Hamilton Sundstrand evaluated options for reformatting the data and shared those solutions with each other. In the end, NASA reformatted the data product because it was the easiest solution for everyone concerned.

While being open and honest about the real drivers behind our negotiation strategies went against our bargaining instincts, it enabled us to work together more efficiently toward a common goal: a mutually acceptable agreement that ultimately met all parties’ objectives.

Team commitment was critical to integrated safety analyses. Hamilton Sundstrand had successfully completed safety reviews for the Sabatier system as a stand-alone piece of hardware, and thus met their contractual requirements. But when the ISS program began to perform integrated safety analyses six months prior to flight, a number of issues arose concerning a vent line the Sabatier would share with the oxygen-generation system. Hamilton Sundstrand provided critical expertise not only on the design and operation of their system, but on the approaches they had identified for mitigating risks discovered in the integrated analysis. If the contractor had not helped resolve these issues, they would have met their contract requirements, but NASA would never have been able to install and activate the system. In more traditional contracting relationships, problems such as these could have led to cost increases and delays.

Developing the Approach and Requirements

Part of the challenge to successfully implementing this contracting approach was communicating what the benefits and risks were to both NASA and the contractor organizations. We also needed to create custom contract clauses that defined termination liability for every day of the contract and the 100-percent look-back penalty. The contractor had to ensure the return on investment was sufficient to account for the fact that funds would be spent in 2008–2009 but payments would not be made by NASA until 2010–2014, so the “cost of money” had to be included in profit calculations. The decision to make early milestone payments had the additional impact of reducing life-cycle costs to the government by providing some funding up front. This reduced the cost of money to Hamilton Sundstrand, and the contractor has the potential to realize financial returns commensurate with its risk, provided the system works as promised.

Technical and schedule issues presented their own challenges. The overall schedule was under two years, a significant challenge for developing any piece of spaceflight hardware that contains what is essentially a furnace, a multistage compressor, and a condenser/phase-separation system. Developing the compressor was a key technical concern. All previous work on the part had been done by NASA, so Hamilton Sundstrand would need to get up to speed on that technology quickly.

To help mitigate risk, NASA limited its requirements to technical interfaces and safety. Requirements related to the launch environment and system reliability were removed because NASA would not pay for any service if the hardware did not survive the launch or was otherwise unusable. Items such as the failure modes and effects analysis and the hazard analysis were retained along with the requirements of normal safety review panels. This allowed more than 70 percent of NASA’s standard requirements to be removed. Verification of the remaining requirements was left as flexible as possible, and specific verification criteria were defined only where absolutely required. In many cases, certificates of compliance from Hamilton Sundstrand were accepted as verification compliance.

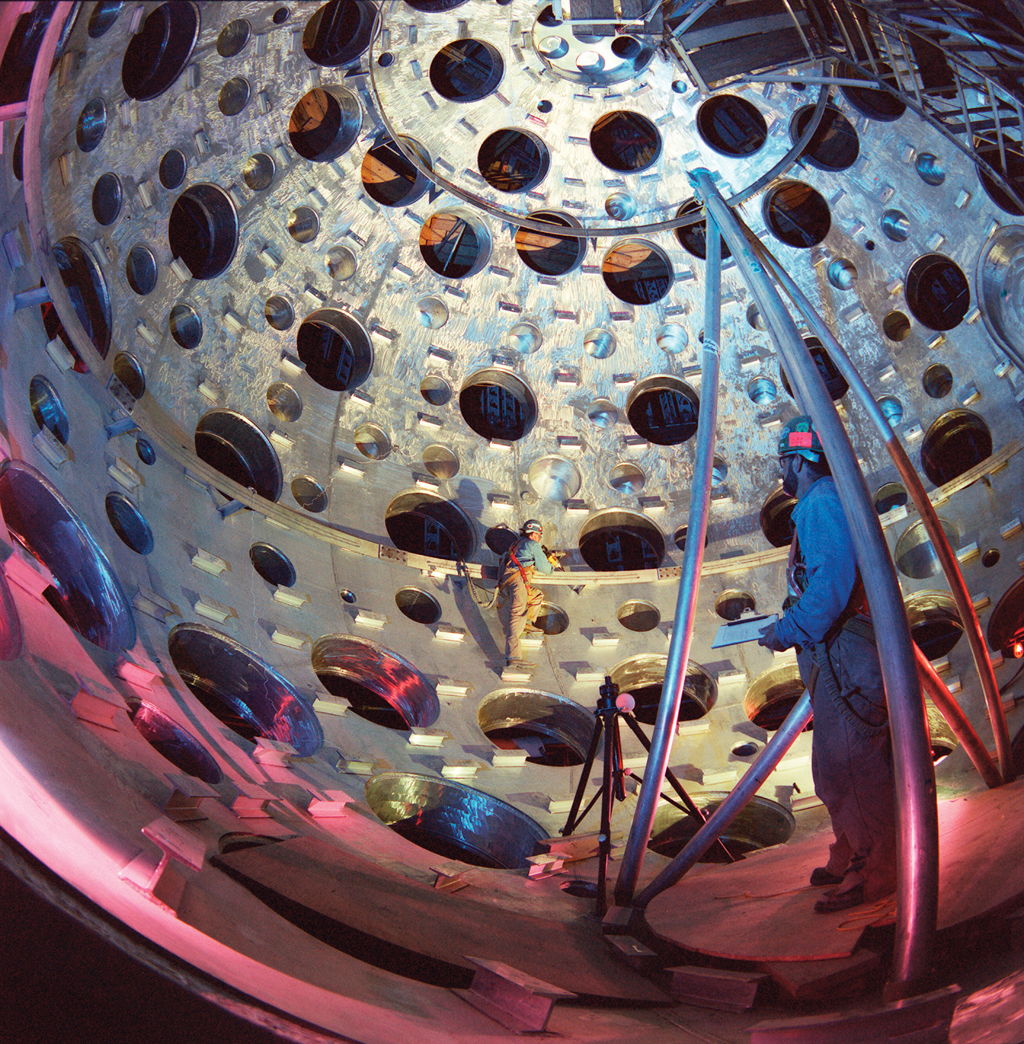

In the Tranquility node aboard the International Space Station, NASA Astronaut Doug Wheelock, Expedition 25 commander, works to install the new Sabatier. ( Photo Credit: NASA

One of the other unique aspects of the contract is that NASA did not require commitment to a specific launch date or launch vehicle for the hardware. Instead, the agency gave itself and the contractor a six-month window from final delivery of the hardware to launch and on-orbit checkout.

Since NASA’s contracting goal was for Hamilton Sundstrand to take on the majority of the risk, and we knew from experience that initial activation of a system on orbit is always challenging, there was a grace period in the contract to allow the contractor to work through any start-up issues before the look-back penalty took effect.

The performance-based criteria didn’t end after activation; they apply to the entire on-orbit life cycle. To simplify the on-orbit criteria, we created a system to calculate the number of days the Sabatier is available for water production. The performance payment for any given year is a simple calculation that subtracts down days from a maximum payment based on full-time functioning. We also defined protocols covering contingency scenarios to address whether system inoperability related to NASA interfaces or the Hamilton Sundstrand system.

What We Learned

The Sabatier hardware was activated on orbit in October 2010 and successfully passed its checkout period. This meant we did not need to exercise the look-back clause for initial milestone payments. Future payments depend on the hardware continuing to be available to produce water onboard the ISS.

A number of things helped make this service-contract approach work well:

- Fully defining safety and interface requirements, as well as minimal verification requirements, at the beginning of the project

- Defining roles and responsibilities for both NASA and the contractor, from the working troops all the way through the highest-level management

- Having an experienced spaceflight-hardware contractor

- Having sufficiently mature technology to keep hardware development risk low

- Making NASA’s expertise openly available to the contractor

- Fostering open and honest communication regarding business goals and limitations, legal options, issues, and drivers for both parties

Additionally, the roles of NASA and the contractor during certification for flight readiness must be defined so NASA teams understand the limits of their role and don’t inadvertently add requirements that are typical of “normal” contracts. Coordination with other contractors who will interact with the new hardware is also important. For example, our unique contract approach and the fact that NASA is not taking ownership of the hardware had numerous effects at Kennedy Space Center, where Boeing and Lockheed Martin are responsible for performing some operations on flight hardware to prepare it for launch to the ISS. Since NASA was not taking ownership, the data required for the property and accounting systems used by Boeing to track hardware they were performing work on could not be provided. It was impossible to assign a value to the hardware for the accounting system since NASA did not know what Hamilton Sundstrand had really spent on the hardware, and the value was ultimately dependent on how the hardware performed on orbit. As a result, the hardware sat for days in shipping and receiving until workarounds could be developed and implemented.

This contract approach delivered process efficiency and innovation but drove out innovation in hardware and software design, given the contractor’s need to minimize the risk of hardware failure in order to maximize profit. Even though failure was an option for NASA, since our risk was minimal, the incentive for the contractor to succeed was much greater. This suggests that the service-contract approach can work well for some technology initiatives, but not all. For instance, it would not be feasible for high-risk, innovative development. And it might be difficult to give contractors so much independence when they are building critical systems that must work. But there are many situations where this approach can benefit both NASA and its contractors. We should think about when and how it is appropriate. Successful flight-hardware development does not mean always defaulting to a cost-plus-fee contract.

About the Authors

|

Jason Crusan serves as chief technologist for the Space Operations Mission Directorate at NASA Headquarters, where he is principal advisor and advocate to the Associate Administrator for Space Operations on matters of technology policy, investments, and initiatives. Since joining Headquarters in 2005, he has been driving an entrepreneurial approach to managing projects by leveraging investments and partnerships with industry, academia, government agencies, and national laboratories. | |

|

Marybeth Edeen has been at NASA for twenty-three years and managed the development of hardware required to enable ISS to accommodate a six-person crew. She is currently the manager of the ISS National Lab Office, which finds and enables uses of the ISS by the private sector and U.S. government agencies outside NASA. | |

|

Kevin Grohs is currently the Sabatier program manager at Hamilton Sundstrand. He has worked in contracts administration, operations management, and program management over the past twenty years in their Windsor Locks facility. | |

|

Darren Samplatsky is the engineering manager for the Sabatier Assembly at Hamilton Sundstrand Space Systems in Windsor Locks, Conn. |