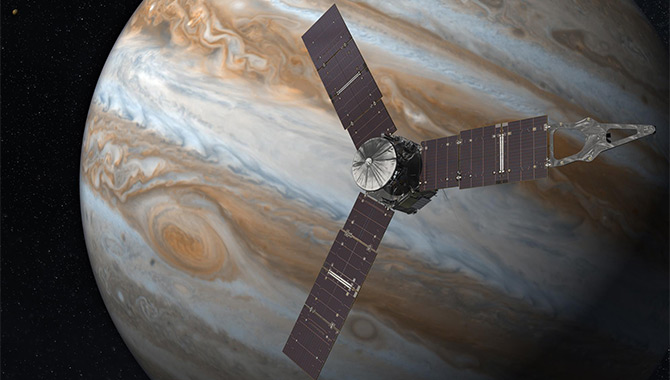

Artist’s rendering of Juno spacecraft approaching Jupiter.

Image Credit: NASA/JPL-Caltech

On July Fourth as America celebrated the birth of a nation, the NASA community had additional cause for celebration as Juno successfully entered Jupiter’s orbit on a mission to investigate the birth of our solar system’s largest planet.

After an almost five-year journey to Jupiter, Juno begins a 16-month scientific probe in October to measure the amount of water and ammonia in the deep atmosphere of the Jovian world, map Jupiter’s intense magnetic field, observe the planet’s auroras, and investigate the existence of a solid planetary core.

“A mission to Jupiter is very challenging, and we have a lot of lessons learned,” said Rick Nybakken, Juno project manager at NASA’s Jet Propulsion Laboratory in Pasadena, California. “The team did an incredible job to meet the challenge of going to the most hazardous planet in the solar system, an environment that’s unparalleled in terms of the intensity of radiation and magnetic fields.”

Creating a culture of collaboration

Focusing on creating an atmosphere of collaboration from the beginning is one of the keys that made a very difficult job rewarding and enjoyable for the team. Collaboration, in essence, became part of the culture of the Juno project, starting with the selection of the project management team members and continuing in relations with spacecraft contractor Lockheed Martin and payload providers.

Initial project manager Rick Grammier (deceased) focused from a technical perspective on putting together a team that could develop effective requirements, get the spacecraft and payloads built, and address specialty engineering elements unique to a mission to Jupiter. From a science perspective, Scott Bolton, Juno principal investigator at the Southwest Research Institute in San Antonio, focused on building a world-class science team that would work together.

The Juno team celebrates at NASA’s Jet Propulsion Laboratory in Pasadena, California, after receiving data July 4, 2016, indicating the Juno mission entered orbit around Jupiter. Rick Nybakken, center, hugs Richard Cook, JPL’s acting director for solar system exploration. Photo Credit: NASA/JPL-Caltech“Scientists are no different from engineers. They have their perspectives and opinions,” said Nybakken. “This is understandable when you consider that Juno carries nine instruments with 25 sensors and the discussions about observational priorities and strategies have the potential to get very intense. So Scott focused on not only putting together a team that was world-class, but that would also play well together.”

Nybakken said it’s inevitable that egos will get involved, but credited “healthy egos” with helping Juno succeed. “In this business, you need to have a strong ego or persistence to work through the unique challenges that we face in these complex missions. In some cases, I’ve sometimes seen folks become rude, too aggressive or they demean people publically,” he said. But that wasn’t the case on Juno.

Celebrating success

“When you have a collaborative team there’s always a lot of interactive support because you enjoy working with one another. This eventually comes full circle because with every successful event you enjoy celebrating and sharing that moment with the team. You don’t have to force it,” said Nybakken. “That’s one of the things that made working on Juno a very unique experience. We really enjoyed working with each other and spending time together.”

Juno was in development for five and a half years before launching in 2011 and in cruise for almost five years, so they took advantage of incremental celebrations.

“I think it’s important to celebrate every opportunity,” said Nybakken. “You don’t go overboard, but you find ways to express authentic appreciation to the entire team as well as members of the project who undergo a lot of stress because their area had so much work and they still delivered on time.” NASA Honor Awards, JPL bonus awards, certificates of appreciation, and dinner celebrations are some of the mechanisms the Juno project has used.

Adding a final touch to design review rehearsal

One of the best practices adopted early on was to require “final quality” slides during dry runs of the project and flight system Preliminary Design Review (PDR), Critical Design Review (CDR), Systems Integration Review (SIR) and subsequent reviews. Nybakken said in addition to the benefit of improvements in time management, page count control and presentation content, this approach provided more consistent and tightly integrated handling of critical topics across the project.

“The beauty was that we could make sure the whole story held together even with all the challenging environments and special topics we had to address,” said Nybakken. “The same topic might affect system design performance, planning, schedule and delivery, and we might hit it five or 10 times from different perspectives during the review, and we wanted to make sure we didn’t contradict ourselves and that we had a consistent message that made sense and could really help headquarters and the review boards.”

He said treating dry runs like final reviews allowed the team to catch disconnects, gaps and errors, and resulted in better presentations that ensured the audience clearly understood the intended message.

Nybakken is a big proponent of complete presentation packages in design reviews because they help the whole team understand what’s going on and ultimately serve as a tremendous historical resource not only for the team, but also for future projects.

“You want to talk about lessons learned and how people can pick things up? One way is to get your hands on well-constructed design review packages. I would say that the Juno PDR, CDR, and SIR are excellent examples of how we handled and accomplished key challenges on the project,” said Nybakken.

Jupiter’s north polar region is coming into view as NASA’s Juno spacecraft approaches the giant planet. This view of Jupiter was taken on August 27, 2016, when Juno was 437,000 miles (703,000 kilometers) away. Photo Credit: NASA/JPL-Caltech/SwRI/MSSSLeaning and learning

Nybakken, who joined the Juno project in 2006 as the deputy project manager and became project manager after launch, said the Juno team probably leaned more on lessons learned from successes than failures. “Most processes and design and test documentation are largely built on successes, but a lot of them have been fine-tuned in response to failures,” he said. “In general, lessons learned were built on successes and enhanced by failures.”

The Juno team benefited from lessons learned on previous missions, perhaps most notably Galileo because it was the only mission to orbit Jupiter and Mars Reconnaissance Orbiter (MRO) because it was one of the more recent spacecraft Lockheed Martin had built. The Galileo mission generated a lot of useful data on radiation and challenges with the Jupiter environment. Juno ended up flying a lot of the same avionics as MRO and benefited from lessons learned through a variety of avionics issues overcome during that mission.

The Juno team captured additional lessons learned through its own experience over the past decade, including:

- Benefits and risk of an extended definition and planning phase. A 30-month Phase B gave the team time to complete design trades and mature requirements, but introduced a lack of urgency that contributed to some late deliveries at the subsystem level. An ASK Magazine article discusses how the team took advantage of the extended Phase B.

- Early and constant focus of payload accommodation. With nine instruments on Juno, payload accommodation was critical. The payload and spacecraft teams used “roadshows,” multiple models, Technical Interchange Meetings, workshops and telecons to define and mature interfaces and build relationships that were essential to resolving integration and test problems later in the project life cycle.

- Creation of cross-project working groups. Formation of cross-project working groups brought unified focus to environment definition, design requirements, design implementation, and integration and test both horizontally with the science, spacecraft ad payload teams and vertically with the system, subsystem, box and component teams in order to complete development on schedule.

- Maximum use of contractors’ existing documentation and processes. To improve efficiency and teaming, the project made maximum use of contractor and instrument providers’ existing documentation and processes, which were reviewed against project requirements and implementation approaches to identify and resolve gaps.

- Use of resident engineers at contractor facility. Juno located several key personnel at the Lockheed Martin facility to work closely with spacecraft development and integration/test teams to maintain an effective partnership with the contractor team and provide the needed level of insight into critical activities.

The Juno team has captured numerous other lessons learned through different stages of the project. More detailed Juno lessons learned are available in the NASA Lessons Learned system. For a glimpse into technical challenges of the Juno mission, watch the NASA Juno mission trailer, Jupiter: Into the Unknown.