The Sustainable Flight Demonstrator will test a lightweight, ultra-thin wing spanning 170 feet, attached at the top of the fuselage, and supported from below by a sweeping brace, shown here in an artist illustration.

Credit: NASA

Sustainable Flight Demonstrator will flight test innovative truss-braced wing.

When President Dwight D. Eisenhower signed the National Aeronautics and Space Act in 1958 creating NASA, the new agency absorbed the resources, projects, and 8,000 employees of the National Advisory Committee on Aeronautics (NACA), and with them the charge to improve the usefulness, performance, speed, safety, and efficiency of aeronautics and preserve the United States as an international leader in aeronautics technology.

NASA tested Digital Fly-By-Wire technology by fitting the electronic flight-control system and computers into a heavily modified F-8 Crusader single-engine, supersonic fighter jet. The computer is partially visible in the avionics bay at the top of the fuselage. Between 1972 and 1985, NASA conducted 211 test flights.

Credit: NASA

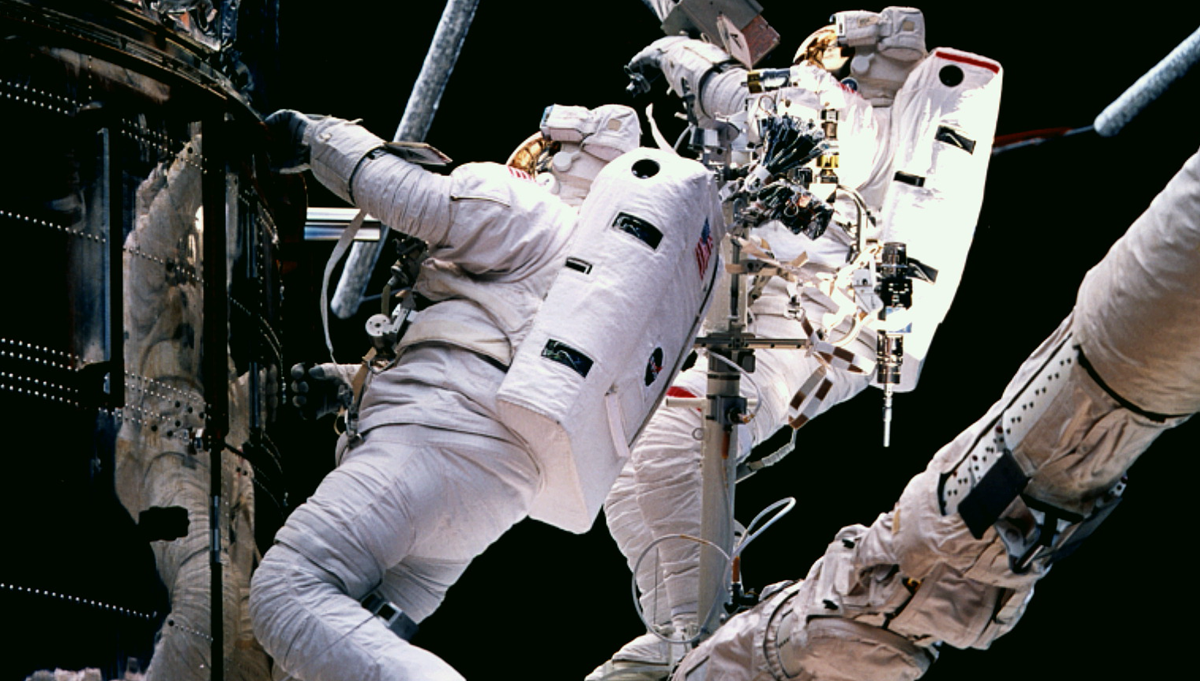

In the decades to follow, NASA developed and matured technologies that pushed the boundaries of aeronautics, testing new materials, new designs, and new control systems. Many of these technologies have made their way into commercial aviation, often with transformative results. The digital fly-by-wire systems NASA developed and tested in the 1970s and 1980s are now ubiquitous in the industry, making commercial airliners both more maneuverable and more stable. NASA engineers pioneered the upturned winglets at the end of aircraft wings that improve fuel economy and reduce noise. NASA has worked to develop collision-avoidance technology, tools that help pilots find safe alternatives around bad weather, and systems to guide remotely piloted aircraft.

“You may not know it, but every time you fly, you’re surrounded by technologies that NASA has helped develop over decades that improve your experience and also make your flight safer and more sustainable,” NASA Deputy Administrator Pam Melroy said in a January press conference.

In 2023, NASA will begin flight testing two new technologies. The X-57 Maxwell is a small, lightweight experimental airplane that uses 14 electric motors where a conventional aircraft would use two internal combustion engines. It will reduce average operating cost per hour from the $440 of a traditional plane to $275. The X-59 Quesst employs a unique shape and technology to reduce sonic booms to a gentle thump when heard from the ground.

“And if we can accomplish that, people across the world are going to be able to fly over populated areas supersonic to get to their destinations faster,” NASA Administrator Bill Nelson said at the January press conference, which highlighted NASA’s work in aeronautics and was held to announce a public-private partnership between NASA and Boeing to further develop and conduct flight tests of a revolutionary new wing.

NASA Administrator Bill Nelson holds a model of an aircraft with a Transonic Truss-Braced Wing during a news conference on NASA’s Sustainable Flight Demonstrator project, Wednesday, Jan. 18, 2023, at the Mary W. Jackson NASA Headquarters building in Washington, DC.

Credit: NASA/Joel Kowsky

“NASA has selected Boeing as our partner in designing, building and flying a brand new, large scale, experimental airplane called the Sustainable Flight Demonstrator. And Boeing’s concept is a Transonic Truss-Braced Wing, single aisle aircraft…,” Sen. Nelson said.

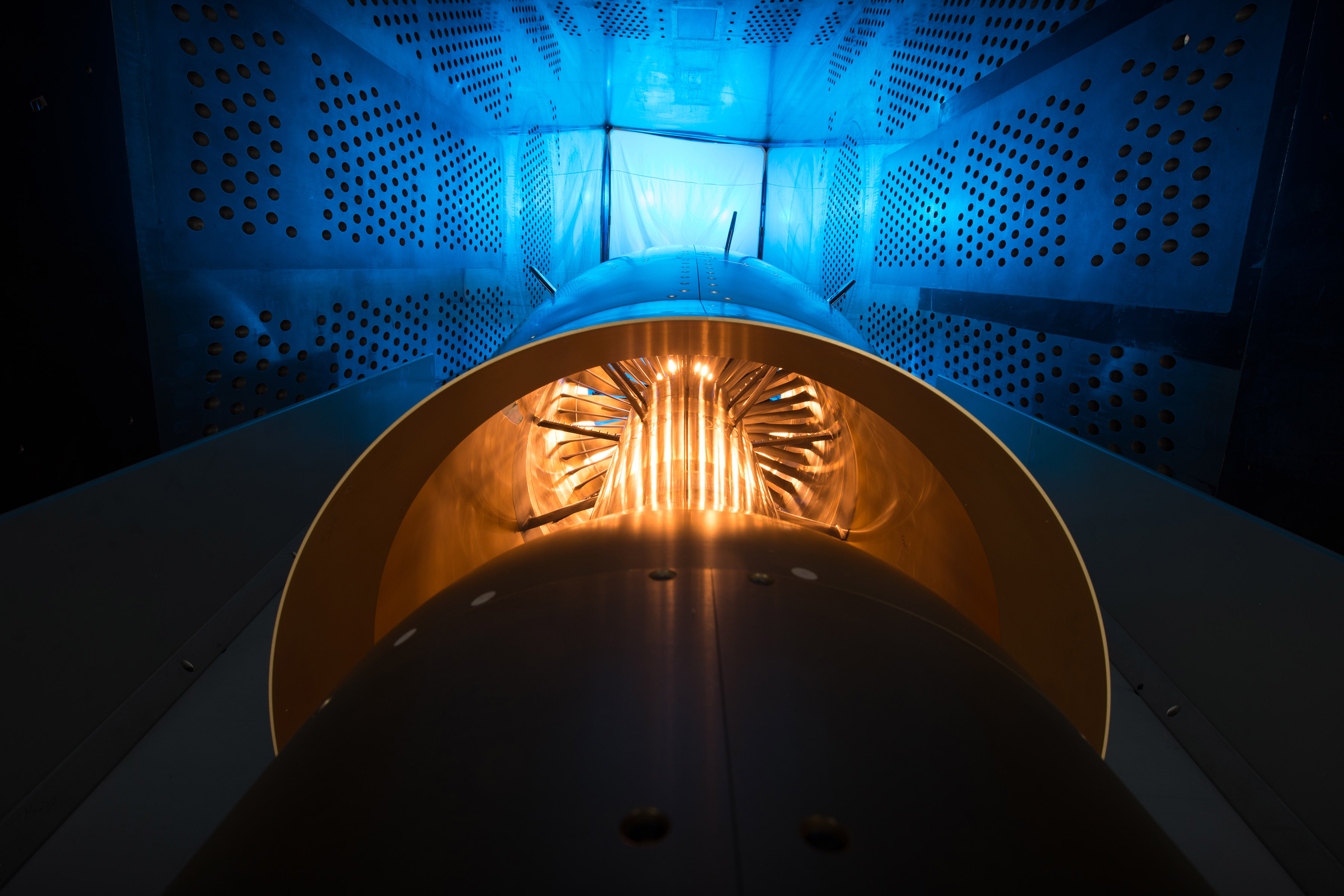

Boeing unveiled an iteration of the Transonic Truss-Braced Wing (TTBW) in 2019. It was then the product of nearly a decade of research and development work with NASA, including extensive wind tunnel testing at NASA’s Ames Research Center. The TTBW configuration that emerged from that testing was a lightweight, ultra-thin wing spanning 170 feet, attached at the top of the fuselage, and supported from below by a sweeping brace.

“The aerodynamics of this kind of a configuration have actually been known for a long time. If you increase the aspect ratio of a wing, you naturally lower the induced drag of that airplane, the drag due to lift,” said Bob Pearce, NASA associate administrator for the Aeronautics Research Mission Directorate. “We know that if we do this, you get better aerodynamics, you get less drag, you burn less fuel. … The challenge is, how do you build that wing? How do you get the structure to work without adding a lot of weight? Because if you add weight, then you lose the aerodynamic benefits of a configuration like that. So, it took advancements in materials, advancement in structure, and so forth to develop that concept. You see the brace as part of that.”

NASA will provide technical expertise and the use of agency facilities to develop the technology and invest $425 million over seven years. Boeing and industry partners will contribute an estimated $725 million. The schedule includes a first flight of the Sustainable Flight Demonstrator in 2028. If flight testing validates the technology, it could inform the design of future commercial aircraft as soon as the 2030s.

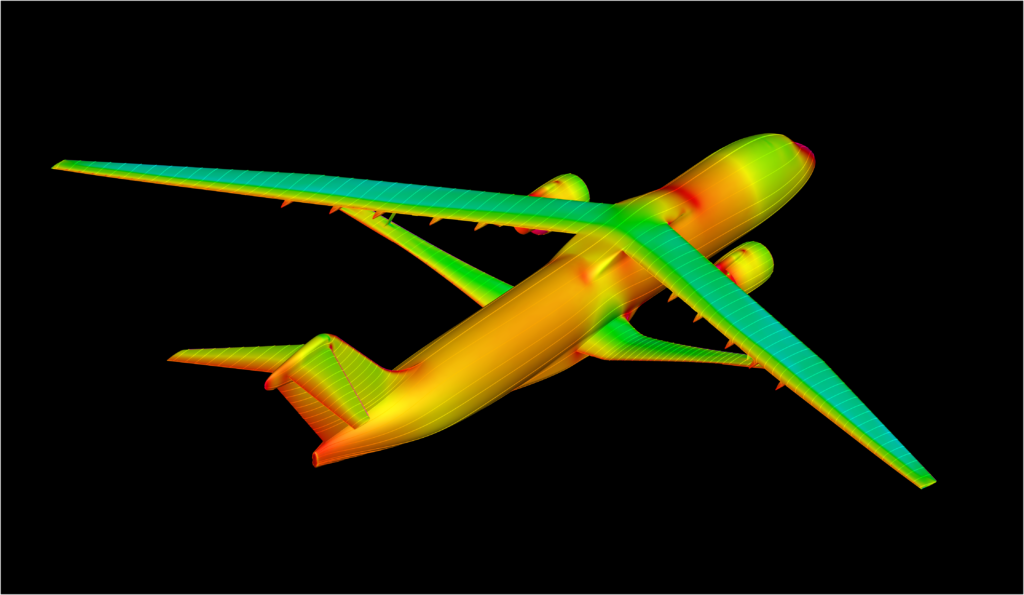

In this image, created with data from a wind tunnel test, the red and orange areas represent higher drag, and the green and blue areas represent lower drag.

Credit: NASA/Craig Hunter

Research by Boeing indicates that the TTBW design alone could lead to significant fuel consumption savings. When combined with fuel efficient propulsion technology currently under development, those savings could add up to a 30 percent reduction in fuel consumption and carbon emissions for single aisle aircrafts, which are the workhorses of many commercial fleets.

“NASA is working toward an ambitious goal of developing game-changing technologies to reduce aviation energy use and emissions over the coming decades toward an aviation community goal of net-zero carbon emissions by 2050,” Pearce said, in a NASA press release.

That effort, the Sustainable Flight National Partnership, includes projects to increase the amount of light-weight composite materials used in aircraft construction, increase the efficiency of turbofan engines, and develop hybridized aircraft that use several megawatts of electric power to optimize turbine engines.