The Space Shuttle Endeavour, now in launch configuration, is covered by a protective wrap as construction continues on the new Samuel Oschin Air and Space Center, at the California Science Center in Los Angeles. Photo Credit: California Science Center

The California Science Center stacks Endeavour in launch configuration for a dramatic new display in a new facility.

On May 16, 1992, Daniel C. Brandenstein lined up the Space Shuttle Endeavour with the landing strip at Edwards Air Force Base and brought the newest addition to NASA’s shuttle fleet in for a soft landing. Endeavour was the fifth Space Shuttle NASA built, and the last. It was slightly lighter than earlier shuttles, but it flew the same. Endeavour was a beautiful vehicle, Brandenstein recalled later in an oral history. It had “performed like an old pro” during its first flight, STS-49.

About 65 miles to the south, officials at what is now the California Science Center, were working that year on an ambitious 30-year master plan to develop the largest hands-on science center on the West Coast at their location in Los Angeles’ Exposition Park.

“When we did that, we identified major portions of the building and some major elements that would be in those exhibit areas that may influence our needs for space,” said Jeffrey N. Rudolph, President and CEO of the California Science Center. Recognizing the power of aircraft and spacecraft to inspire future generations, they set their sights on a 20-story, 500,000-pound acquisition.

“We said, ‘Someday NASA will retire the space shuttles, and we should try to get one,’ ” Rudolph said. And almost 20 years later, that’s what happened.

By using flight hardware in the display, the Center was able to use NASA engineering models to validate the seismic capacity of the stacked components. Photo Credit: California Science Center

Endeavour arrived at the California Science Center on the evening of October 14, 2012, following a 12-mile, 68-hour trek through the streets of Los Angeles. About 1,000 police officers lined the route, keeping throngs of spectators away from the behemoth spacecraft, standing nearly 60 ft. tall, with a 78-foot wingspan. Crews removed about 220 traffic signals and more than 400 trees to clear the way for Endeavour, which passed some obstacles on the route by a fraction of an inch.

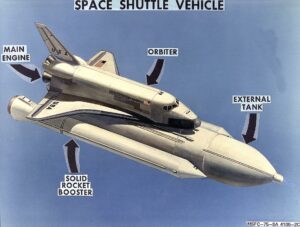

Later that month, the shuttle was on display. But the center always had much more ambitious plans for Endeavour. The master plan included a rendering of a space shuttle in launch position, complete with solid rocket boosters (SRB) and External Tank.

“At the time of the master plan, the expectation was that the stack would use a replica External Tank and replica Solid Rocket Boosters,” said Dennis Jenkins, an aerospace engineer who worked on the space shuttle program. Jenkins became the United Space Alliance project manager charged with delivering the orbiters to their display sites. Afterward, he continued helping each of the museums with their final displays. He is the Project Director for the new Samuel Oschin Air and Space Center, which will house Endeavour.

“As we started looking at the various engineering requirements, particularly the need to counter potential seismic events in Southern California, it became obvious that using replica hardware was going to drive us to a major engineering project, particularly developing high fidelity structural models for the stack,” Jenkins explained. “This was not affordable. A quick evaluation of the hardware models we used during the flight campaign showed that the flight loads largely enveloped the seismic loads.” This meant that if the center used flight hardware, they could use existing models to validate the seismic loads.

Because the space shuttle’s solid rocket boosters were jettisoned about two minutes into flight, recovered and reused, NASA was able to transfer the aft skirts, forward skirts, frustums, and most of the structural components the center needed. Northrop Grumman donated a set of flight Solid Rocket Motors. Unlike the boosters, however, the 154 ft tall, 59,000-pound external tanks were jettisoned 10 seconds after main engine cut-off on orbit and broke apart in Earth’s atmosphere over the Indian Ocean. There was exactly one flight-certified External Tank available. Designated ET-94, it was at NASA’s Michoud Assembly Facility, where investigators had inspected it and dissected foam from various parts of the tank as part of the investigation into the Columbia accident.

ET-94 was shipped by barge, traveling from Michoud through the Panama Canal to Los Angeles, then over city streets to Exposition Park. “Although ET-94 looked pretty rough when we received it, it was all cosmetic damage resulting from various tests the Columbia Accident Investigation Board (CAIB) and SLS performed on the tank over the years. We did a lot of foam restoration but structurally the tank was in perfect shape,” Jenkins said.

Designing the Samuel Oschin Air and Space Center presented the team with some formidable challenges. One was determining if there was a way to build the building and then install the SRBs, External Tank, and Endeavour.

“We ended up initially planning that and then figured out it just couldn’t be done,” Rudolph said. “The second challenge that hit us pretty early was that building a space 200 feet tall with no columns and no shear walls—because we wanted these clear views of the shuttle—is not simple in a seismic zone. The engineering and design of the building is quite complex and quite expensive, but it’s well worth it.”

The SRBs’ aft skirts were the first to be lowered by crane, then bolted down by high-performance alloy studs, 9 ft long, that extend through the entire seismic isolator.

The stack sits on an 1,800-ton concrete pad founded on six triple pendulum seismic isolators. Each of the isolators are 55 inches square and about 17 inches tall. They can move about 36 inches laterally. In an earthquake, the shuttle and the building would react independently. The SRBs’ aft skirts were the first to be lowered by crane, then bolted down by high-performance alloy studs, 9 ft long, that extend through the entire seismic isolator.

“This was a fun project because the studs needed nearly 500,000 foot-pounds of tension, requiring a custom-built hydraulic tensioner that stretched each stud about 3/8th of an inch. We then surveyed the skirts again to make sure they were still properly positioned and level,” Jenkins said. Because they were empty, the 11 case sections of the SRBs were preassembled and installed as single units.

The most challenging part of the sequence was lowering the External Tank onto the thrust posts of the SRBs with a giant crane. With less than an inch of clearance between the tank and the scaffold-clad SRBs on either side, towering over the partially constructed walls below, the team used straps and come-alongs to gain a small amount of additional margin for the delicate maneuver, a technique that was also used at KSC during the shuttle program.

The display will provide guests with spectacular views of Endeavour, its External Tank, and its Solid Rocket Boosters. Photo Credit: California Science Center

“Next up was Endeavour. Although the External Tank was more demanding, we all worried about the orbiter just because the thermal protection system is very fragile and irreplaceable,” Jenkins said. The shuttle was wrapped in a protective coating for the operation, and it went smoothly. Earlier this year, with the components assembled and the fasteners torqued to launch specifications, what the center calls “Go for Stack” was complete.

“We designed the building with a lot of thought as to how we could provide many different places to view Endeavour, and see the whole stack,” Rudolph said. “Now that it’s in, I think all of us honestly—including a few astronauts who have come and seen it—are like, ‘Wow, it’s really great.’ You’ll be able to walk down underneath and look up into the engine nozzles. You’ll be able to go up in a glass elevator and look at the whole stack. You’ll be able to look into the mid-deck. We’ll have a glass platform above the nose of the orbiter, so you’ll be able to look down on it. It’s going to really be exceptional.”

Construction of the new building is proceeding, with the center saying completion will be in a few years, owing to the intricacies of some of the structural elements protecting Endeavour. “The diagrid above it is really complex, with every piece of steel different than every other one. It’s like a big puzzle. We want to see that together before we set a date.”

The Go for Stack process drew intense public interest, not only in Los Angeles and California, but nationally and internationally as well. Tourism officials note this could translate into a $3 billion boost in the local economy once the Samuel Oschin Air and Space Center opens.

“It’s not just that it feels good that it’s done. Seeing it, and seeing what we dreamed about, it’s rare that you say, ‘it’s better than we thought.’ I think everybody on the team feels that way about it now,” Rudolph said.