NASA’s Nettie Roozeboom discusses a new state-of-the-art technique to measure unsteady aerodynamics using pressure-sensitive paint.

New tools and techniques are necessary for NASA and its stakeholders to develop advanced aerospace vehicles. Through a connection established between the Unitary Plan Wind Tunnel and the NASA Advanced Supercomputer, both located at NASA’s Ames Research Center, rapid transfer, processing and display of high-speed, pressure-sensitive paint data from the wind tunnel demonstrated the ability to make real-time decisions that could decrease design cycle time.

In this episode of Small Steps, Giant Leaps, you’ll learn about:

- The Unsteady Pressure-Sensitive Paint Capability Challenge

- Breakthrough moments in the application of state-of-the-art tools and techniques

- Why this activity is transformational in the design of advanced aerospace vehicles

Related Resources

From Wind to Data, in No Time Flat: Accelerating Spacecraft and Aircraft Design

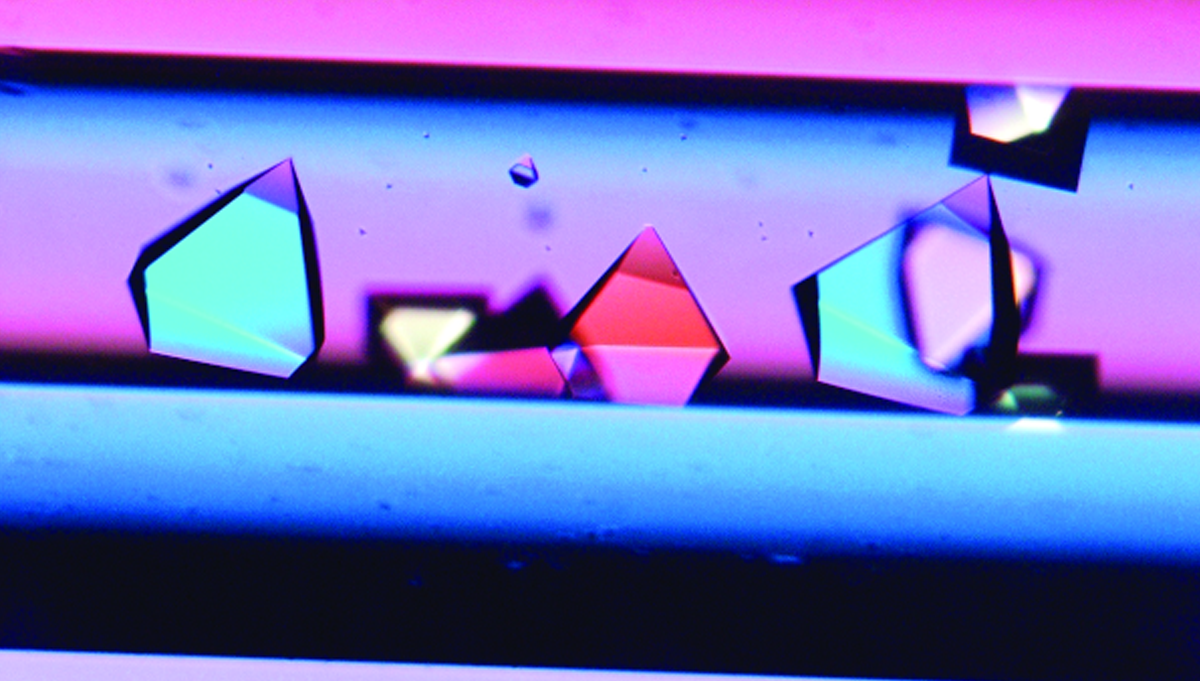

Power of Pink Provides NASA with Pressure Pictures

Guide for Pressure-Sensitive Paint Testing at NASA Ames Research Center Unitary Plan Wind Tunnel

NASA Advanced Supercomputing Division

APPEL Courses:

Space Mission Operations (APPEL-vSMO)

Foundations of Aerospace at NASA (APPEL-vFOU)

Requirements Development and Management (APPEL-vREQ)

Nettie Roozeboom

Credit: NASA

Nettie Roozeboom is the Project Manager for the NASA Aeronautics Research Mission Directorate’s Aerosciences Evaluations and Test Capabilities (AETC) Unsteady Pressure-Sensitive Paint (PSP) Capability Challenge. Roozeboom specializes in the application of PSP technology in production wind tunnels and has led the PSP efforts at NASA Ames Research Center’s Unitary Plan Wind Tunnel since 2011. She has conducted PSP measurements on a variety of vehicles from across the aerospace sector, including NASA’s X-Planes, Space Launch System and Commercial Crew Program as well as Department of Defense and commercial aviation. Roozeboom began her NASA career in 2007 as an intern and joined the agency in 2008. She has a bachelor’s in mechanical engineering from the University of Tennessee and a master’s in mechanical engineering from Stanford University.

Transcript

Nettie Roozeboom: We were looking at data that had never been measured or seen before in that resolution.

This is that surface pressure measurement. That’s what everybody is after. And now we have this time history of what the pressure is doing on the surface of the vehicle. This becomes the holy grail of the data set that you want.

Host: You’re listening to Small Steps, Giant Leaps, a NASA APPEL Knowledge Services podcast where we tap into project experiences to share best practices, lessons learned and novel ideas.

I’m Deana Nunley.

As NASA and its stakeholders develop increasingly advanced aerospace vehicles, more advanced tools are required for efficient design. NASA is working on a new state-of-the-art technique to measure unsteady aerodynamics using pressure-sensitive paint, high-speed cameras, and advanced image processing methods. Nettie Roozeboom works at NASA’s Ames Research Center as the Project Manager of the Unsteady Pressure-sensitive Paint Capability Challenge in the Aeronautics Research Mission Directorate.

Nettie, welcome to the podcast.

Roozeboom: Hi, Deana. It’s great to be here with you. Thank you so much.

Host: Absolutely. What is the unsteady pressure-sensitive paint capability challenge?

Roozeboom: Yes, it is transforming the ability to assess unsteady flow. And how I like to unpack it is it’s the unsteady pressure-sensitive paint capability challenge. It’s a capability that we deploy in wind tunnels. And it’s a challenge because this really is defining a new state of the art in how we assess unsteady flow. There’s a lot of questions here. We’re looking at a very fundamental problem and fundamental research has to be done. And we really have to show and demonstrate that we really are improving the state of the art. And the unsteady pressure-sensitive paint part of it, pressure-sensitive paint is an optical technique that started in the mid-80s. And this was a partnership between NASA and University of Washington in the early creation of this. And it’s a luminescent molecule that responds to oxygen. Maybe we should really call it oxygen-sensitive paint.

The amount of oxygen is proportional to the pressure. The lower the pressure, the lower counts of oxygen molecules, the higher the pressure, the higher the count of oxygen molecules. And this paint responds to oxygen. The higher the amount of oxygen, the paint will shine dimmer and the lower the amount of oxygen, the paint will shine brighter. It’s a pressure-sensitive paint. And we use this to assess what the pressure is on the surface of a wind tunnel model in the wind tunnel.

And I said, unsteady. The unsteady part of it is at the heart of wind tunnel testing you’re wanting to measure what these aerodynamic forces are on a vehicle. It doesn’t matter if it’s an aircraft or a spacecraft, a launch vehicle. Everybody wants to know what is the pressure acting on this vehicle at different parts of the vehicle? Pressure times an area equals the force. That’s where the pressure-sensitive paint comes in. If we want to understand any kind of flow, steady flow or unsteady flow, we want to know what that surface pressure measurement is and how it’s distributed across the vehicle. The unsteady part of it, that’s the hard part to solve for us. And I’d say that’s even where we have the largest deficit of knowledge and ability. The ability to measure and compute unsteady flows remains a challenge. And it’s one of the biggest challenges within the field of aerosciences. If we want to understand these unsteady flow phenomenon like shocks and shock boundary layer interactions, we have to measure these unsteady pressures.

We do this both in wind tunnels, we do it computationally, but both of these current state of arts are, I’ll say good for today’s requirements. But our requirements are becoming more and more strict, more and more with respect to efficiency of vehicles. And so now the pressure-sensitive paint, since we can measure and have this paint respond at 10 kilohertz, 20 kilohertz, now this can be a path forward to really mature this state of the art of measuring unsteady flow.

Host: What would you say is the overall significance of the activity?

Roozeboom: Traditionally, PSP has been this optical technique that has really been a lab demonstration and deployed in small research labs. And the significance of what we’re doing is moving this to a production wind tunnel. What’s the difference with a production wind tunnel? Currently we’re deploying this at the Ames Research Center Unitary Plan Wind Tunnel and specifically in the transonic facility. This facility is the workhorse of the agency. Everybody from across the aerospace industry comes here to test their vehicles. It can be aircraft, it can be spacecraft, it can be launch vehicles because everybody flies through this transonic regime. Transonic is a little bit below and a little bit above Mach 1, the speed of sound. And this is a very curious place to fly because there’s a lot of aerodynamics and unsteady aerodynamics here.

If we go back and examine NASA’s goals, both on the aeronautics side and on the human exploration side, weaved in there is all about fuel efficiency and designing ultra-efficient vehicles, designing vehicles that will allow a space economy to thrive. So, how do we get more fuel-efficient aircraft, spacecraft? Well, you have to study these unsteady aerodynamic forces.

On the aircraft side, one of the major thrusts for aeronautics is ultra-efficient vehicles. This can look like designing a new engine, new fuels that we’re using, but it also is looking at the redesign of the body itself, the actual aircraft body. And one of the places where things get over designed is that we currently cannot measure and assess these unsteady flows. We have to make conservative estimates on how strong and where are these forces are acting on the vehicle so we will beef up that part of the vehicle.

And on the space side, flying through the transonic regime, that is the trickiest part of this. Vehicles in a sense, so from the launchpad and going into space, flying through that transonic regime, that’s really tricky. That’s where you can see a lot of accidents. You can see rockets become unstable. Measuring that appropriately is key in the success of that vehicle. Currently we’re in the middle of this four year project and this project is all about taking this technology from the lab environment to the wind tunnel environment and we have to assess what the challenges are.

Host: What have you demonstrated so far?

Roozeboom: So far, if we go back a few years, again, we started with this very lab-oriented research activity and it was just to get the basic understanding here of operating the high-speed cameras, which would record the emission of the paint, the response to the paint. It was even just how to apply this paint. It was different than the previous paints that we had been using. And so we did several small lab demos just to get our footing. Also to see, what does this data look like? How do we process it? How do we make sense of it at a very fundamental level? And then once we had some basic knowledge on how to deploy this, then we started just building up our ability in the production wind tunnel. The Space Launch System, SLS, they have been a key partner here and it has been a beautiful cross-mission directorate partnership that we’ve been able to perform.

And even if we go back to 2016, this was the first time we interacted with SLS and they were going to do a force-in-moment test. This is just measuring steady forces. And we approached them and said, ‘Hey, we’re developing this new technology. Can we put a single camera in the tunnel? At the end of your test, can we take a day’s worth of data? Or just have a day to be able to paint the model and collect data, starting to get a feel for production deployment of this technology.’ We did that and it was awesome and beautiful and a huge learning curve. And the part that I’ll say, remember this later is after we painted and got ready and everything was set to go, we’d got two hours of data and that was a terabyte. And we came to a screeching halt right at the end of shift because we had filled up our drive. We were so concentrated on everything else that we filled it up and we said, ‘Well, that’s the end of that.’ Thankfully, it was at the end of shift.

And then fast forward a year later, we acquired three more cameras. We had four cameras, one on each wall of the wind tunnel. And we had three days of testing this time and we had gotten a larger computer and maybe been a little bit more mindful, but still after that, SLS came back to the wind tunnel. This time they were doing an unsteady aero assessment test. Using the traditional sensors that we usually use, and again, we said, ‘Hey, at the end of your test, can we piggyback and do another demonstration of this technology and look at if we test multiple days in a row, what do we need to be conscious and considerate of?’

And again, after the end of that first day, maybe we got in six hours of actual data acquisition, we filled up the drive. We had 40 terabytes here. We had to scurry out and get external drives, fill it up and then wipe the machine and get ready for the next day. But we had some really great, again, coming up this learning curve and understanding how do you deploy this technology from the chemistry point of view? From the hardware point of view? From the software point of view? And so we learned a lot. We, we filled up about 12 drives. It was about 50 terabytes, I believe at the end of three days of testing. And after that was done, we walked over to the NASA Advanced Supercomputer down the street and we uploaded them from a hard drive to the supercomputer. At least we had a place to store all this data together and it wasn’t just on these external hard drives.

And then fast forward two years later. This was September 2019. This was going to be our most sophisticated test yet. And we had to start thinking to be more conscious of what we were going to do, how we were going to collect this data and how we would do this in a production wind tunnel, without decreasing that productivity. After that test, we really demonstrated that we could deploy this technology in a production wind tunnel and we could collect this really useful data. It was a large data set. It was a rich dataset. This was a transformational dataset.

Host: Could you tell us more about why this is considered transformational?

Roozeboom: Yeah. If we could go back and review, this is that surface pressure measurement. That’s what everybody is after. And now we have this timed history of what the pressure is doing on the surface of the vehicle. This becomes the holy grail of the data set that you want. But the hard part is that we have this large data set. We have this rich data set. And if we go back to the fundamentals of supply chain management and you look at something that’s really high value and low weight. This is high value, really low weight. Then you move this data as fast as possible.

I mentioned that after that demo, we had it on external drives and we walked it over to the supercomputer and we uploaded it. This is not traditionally how you get data to the supercomputer. We knew we had a little bit of time before our next test and about a year before this next demo, which was in September of 2019, we started talking with the NASA Advanced Supercomputer, which is also located at Ames Research Center. And we had moved the data there. We had started developing our software to process the data on the supercomputer. And when it was on hard drives, we really lacked that ability to process it and then how do we even deliver it? Traditionally, this is right now, our current practice is, you put data on a drive and you ship it. And that, again, satisfies today’s requirements. But again, if we go back, we want to get more fuel-efficient. We want to invite more partners to the space economy. We have to get smarter.

This is really where this transformation comes from. This even starts going into that digital transformation and going down that path of how do we digitize this information? And then how do you deliver it? By partnering up with the NAS, we worked with them for about a year. This is something that had been discussed. This had been attempted. The value here was very obvious of that the experimental facilities, the wind tunnels really needed to talk to these computational facilities. And it wasn’t just the facilities, it was also the communities that needed to talk that we had these multi-discipline areas that really could leverage one another. It was a diverse team. And we could really build something that used the agency’s resources, I think in the most efficient way. So, September 2019 rolled around. Before that we had built this connection between the wind tunnel, the Unitary Plan Wind Tunnel and the NAS advanced supercomputer.

And during that test, we had five days of testing and we were able in real time to move this holy grail of data, the pressure-sensitive paint from the wind tunnel to the NAS, process it and visualize it all within an hour, a matter of an hour from the actual conception of the data point to being able to visualize it. And I think we even got it down to around eight minutes. Whenever we saw that first data point come up and it was being visualized on the hyperwall at the supercomputer, this was really transformational. This was eye-opening that now we could invite the SLS subject matter experts to come look at this data set. We were looking at data that had never been measured or seen before in that resolution. And that was the transformational part of it. It’s like, wow, okay. We’ve got different facilities, we’re leveraging the parts of them that they do the best and then we have the subject matter experts being able to make decisions while they were there at the wind tunnel and being able to see this data.

Host: Wow. That’s fascinating. If you had to isolate one breakthrough moment that propelled this project toward being a game changer, what would it be?

Roozeboom: Yeah, it absolutely was this connecting the wind tunnel facility to the supercomputer. I talked about the pressure-sensitive paint. We kept running up against these limitations of our data acquisition of one terabyte and then 10 terabytes, 50 terabytes. That was always going to be the limiting factor. And it was one of those things where we could go out and find a lot of money, like a million dollars or more and build this beefy mini supercomputer, or we could look around, we could get smart. We could, what I like to say is we could find those leverage points where the minimum amount of activity would cause the greatest amount of gain. And that’s what we did. We found that leverage point and we called this connection Red Rover. I love it because it’s Red Rover, Red Rover, send data right over.

Host: That’s cute.

Roozeboom: Yeah. And it worked. That was the beautiful part of it. And it really, I love this demonstration because it really showed what happens when you have this diverse team, when you have this multidisciplinary team that we, again, we could go out and find all the money in the world, but we still would be working in a realm that we didn’t know very well. And we still would lack a way to deliver this data. This really became, this is a way to transfer, to process, to visualize and deliver that data. That was the major breakthrough. Now really, we can run as fast as we can now with this technology and the abilities that really open up when you have the NAS, the supercomputer. And now we can start looking at these advanced methods of artificial intelligence and machine learning, how do we leverage this for these really rich data sets?

And that also became a breakthrough moment because when you’re looking at 600 data points that has a million points on a vehicle for 50,000 steps in time, that’s mind boggling. That’s not something our human brains can understand or comprehend. We end up looking at like one, two, 3 percent of the data and then if you go back again, it’s like, oh, is this the most? Is this the best use of our facilities? How do we have a breakthrough there? Well, you go to a different environment. That really was what it was. It’s like, you got to get the data in a different environment. Now we can be smarter with the data. We can look at more data points. We can be even more aggressive and creative in how we process this data because it’s in the right environment.

Host: How did you and the team come up with these amazing ideas?

Roozeboom: Yeah. It’s fun. This is the part that I love about engineering and really working at NASA is you got to be creative. When you’re on the frontier, it’s a fine balance between creativity and productivity. It’s hard to do the two at once. And so over the years when we were doing this demonstration and I love to call it the beg, borrow, steal part of the project, it was just trying to each time, it was just a small step forward. And over the years we kept examining, where did the technology fall short? Where did the facility fall short? Where did the customers fall short? Even when we would get these great data sets and you’d say, ‘Yeah, have you looked at the data?’ It’s like, ah yeah, I looked at one point, but it’s new, there’s not tools to be able to look at it. It was new technology, it was large data. It was data that engineers weren’t familiar with.

You can’t just simply throw it over the fence and say, ‘Good luck.’ And you’re also working with a customer that already has deliverables. They have to say what the loads on this vehicle are and they have a deadline. And in that deadline is not a place to like, ‘Oh, can you help, transform this new technology and how you do this assessment?’ So, we had to be very smart and look at where did it fall short? And every solution kept coming up to these three points. It was the tools, the time, the technology. And if we could keep honing our approach to this project and saying, ‘How do we save time? How do we decrease this design cycle time?’

It’s not a one-and-done on wind tunnel tests. You’re going to have a model and you’re going to do a series of wind tunnel tests over many years. And what dictates that is that design-cycle time between each entry. And it really is just can I look at the data? What’s inside the data? How do I navigate to my next test? Could we save the time?

The next part would be, how do we deliver this data? How do we develop tools that allow people to look at the data in the format that they need? What are those data products that the customer needs as we develop those tools?

And then the talent, we are specialists in this optical technique. We are wind tunnel specialists. Understanding how to design an aircraft and a launch vehicle, that’s where we go to our customers and we say, ‘What is this talent? What information do you need to share with us?’ And it’s just having that conversation of we can get there, we just need to have a conversation, understand that talent part of it. And can we mold that into a model that we can now process this data with?

Host: From a programmatic or project management standpoint, what have you learned over the last few years that might be helpful to other individuals in NASA’s technical workforce?

Roozeboom: Yeah, really, this is one of the key parts of the project that I love. And I really look at this project as a place to grow everybody on the team and grow this technology. And so I have a few key phrases that I often bring up to the team. The biggest one that I love is demonstration creates conversation. This capability challenge project is just about demonstrating what we can do and building this capability. If somebody ever comes to me and says, ‘What about this? What about this?’ I say, ‘Can you demonstrate it? If you can demonstrate it, then we can talk about it. Then we can look at it. We can poke holes at it. We can tweak it. We could things better.’

And so that’s, I love looking back at each one of these tests that we’ve done because it was all a demonstration to say, ‘OK, look what we can do. We can put cameras in a wind tunnel. We can paint a model. We can take data. OK, now look at what we can demonstrate. We can put more cameras. We can collect more data. We can move it to the supercomputer. We can process this data. We can show it to people while they’re here — while the subject matter experts are here at the wind tunnel.’ I love that ‘demonstration creates conversation’ piece of it.

Host: Could you share your thoughts on how teamwork fits into this project?

Roozeboom: Oh yeah. Teamwork is my favorite part of the project. Over the past years, we just kept demonstrating little pieces, little steps forward. And we went to our funding authority, the Aerosciences Evaluations and Test Capabilities AETC and we showed them, this is what we’ve done as a few engineers pulling this together to demonstrate what this technology can do. But I told them, ‘I need more of a team. I need a diverse team. I need people who are well versed in signal processing. I need people who are experts in software development, people who are experts in visualization.’ I’ve done each of these to some small level, but it would never be a capability just with my resources or three people’s resources.

It needed to be a multidisciplinary team that would build this technology. And that’s what we’re demonstrating today with this team is that, when you have that multidisciplinary approach, systematic approach to build this, it’s beautiful. We really jive. We’re working together. We’re excited to explore these new frontiers of artificial intelligence, new visualization tools. How do you deal with this large rich data set on a remote server? That’s the beauty, but that’s also the hard part of this. That’s where the teamwork comes in to be able to solve these really complex questions.

Host: What’s next for you and the team and this activity?

Roozeboom: Yeah. I like to say transactions take time, transformations take longer. It’s still going back to this isn’t just purely a transaction. It’s not just collect data, process it and it’s there ready for you. It’s really about transforming how we assess unsteady flow. And I think we’re doing that. The other part is, being really mindful that we’re aligning with the agency’s goals and not just NASA’s goals, but are we aligned with Aeronautics Research Mission Directorate? Are we aligned with the Human Exploration Mission Directorate? And are we aligned with our stakeholders goals? We have to be very mindful in how we approach this technology, how we sell this technology, how we deploy this technology. And if we go back to how is the agency moving? What is the agency doing? How do we take the agency’s lead here?

Again, it comes back to the pressure-sensitive paint technology. Comes back to it’s a large data set. Comes back to leveraging our resources with the supercomputer. And then, a really big thing has happened in the past year. And I think these will be two things that will transform our project and transform our capability. We’ve all been living in this pandemic and it really changed this digital transformation. How do we have access to data? How do we have access to one another? And when we first did this Red Rover connection between the wind tunnel and NAS, this was all a demonstration of getting the subject matter experts there. But then once March 2020 happened and we saw, oh wow, the future of work, the future of travel, the future of even wind tunnel testing has really changed.

Now this is really a delivery mechanism of data. We can process data, we can deliver it. You can be anywhere in the world and have an active role in these experimental tests at the wind tunnel. This is huge. We demonstrate our work and our success can continue even remotely. We’re trying to keep building on this new world that we all live in.

The last comment I would say is, NASA over the summer changed its core value. That’s a huge deal when an agency or a company changes its core values, and it added the value of inclusion. And I love that because when I looked at what we are doing, it falls under that umbrella. Inclusion, just like everything else, it has many different faces. It’s seen across the workspace.

And this was a way to be more inclusive. That you didn’t have to have the requirement to travel to be a part of that wind tunnel test. And this really drove home that real, tangible, technical way to see how NASA realizes its core values. And I really believe this will greatly contribute to the success of the team, the success of the technology and the success of this capability. And I think if we keep looking at where do we invest? If we invest in the people, meaning the culture, the process, their abilities, if we keep investing in the facilities, if we keep investing in the technology, that’s NASA’s product. That’s how we accomplish these big challenging problems is by combining the people, the facilities and the technology.

Many thanks to Nettie Roozeboom for joining us. You’ll find her bio along with links to related resources and a transcript of today’s episode at APPEL.NASA.gov/podcast.

If there’s a topic you’d like for us to feature in a future episode, please let us know on Twitter at NASA APPEL – that’s APP-el – and use the hashtag Small Steps, Giant Leaps.

As always, thanks for listening.