Design of the Little Joe capsules began at Langley prior to the design of the Mercury capsule and was, therefore, a separate design. It was not designed to carry a man but the capsules did have to meet the weight and center of gravity requirements of Mercury and withstand the same aerodynamic loads during the path of lift-off. In comparison with the overall Mercury Project, Little Joe was a simple undertaking, The fact that an attempt was made to condense a normal two-year project into a six-month one with in-house labor turned it into a major undertaking for Langley. Photo Credit: NASA Langley Research Center

Background

A mission’s success often depends on the performance of our suppliers. In a very real sense, suppliers perform relative to how well they are integrated within the larger team. To help suppliers feel like part of the team, the project manager should welcome them immediately upon their selection. Use the most personal vehicle available, such as a face-to-face meeting. The more familiar the project manager becomes with the suppliers the better able he or she will be to develop a strategy for using them. It’s a good idea to assess the strengths and weaknesses of suppliers with evaluation materials. You can also use whatever past performance information may be available. The project manager’s main focus should be developing a positive, long-term relationship with his or her suppliers. Good ones are hard to come by. You want to make sure the good ones realize you appreciate them.

Procedures

- Welcome supplier to the team immediately upon selection.

- Establish regular communication, especially with key personnel and executive management.

- Independently assess supplier strengths and weaknesses using evaluation materials and all available past performance information.

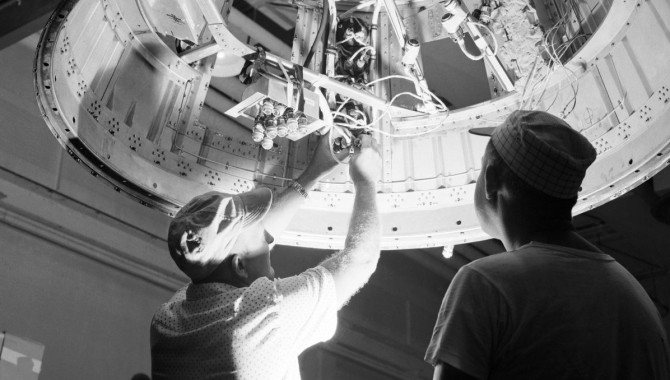

- Visit supplier’s facility as frequently as possible.

- Invite supplier to events at your site and/or major integration site.

- Continue to build the relationship after delivery.

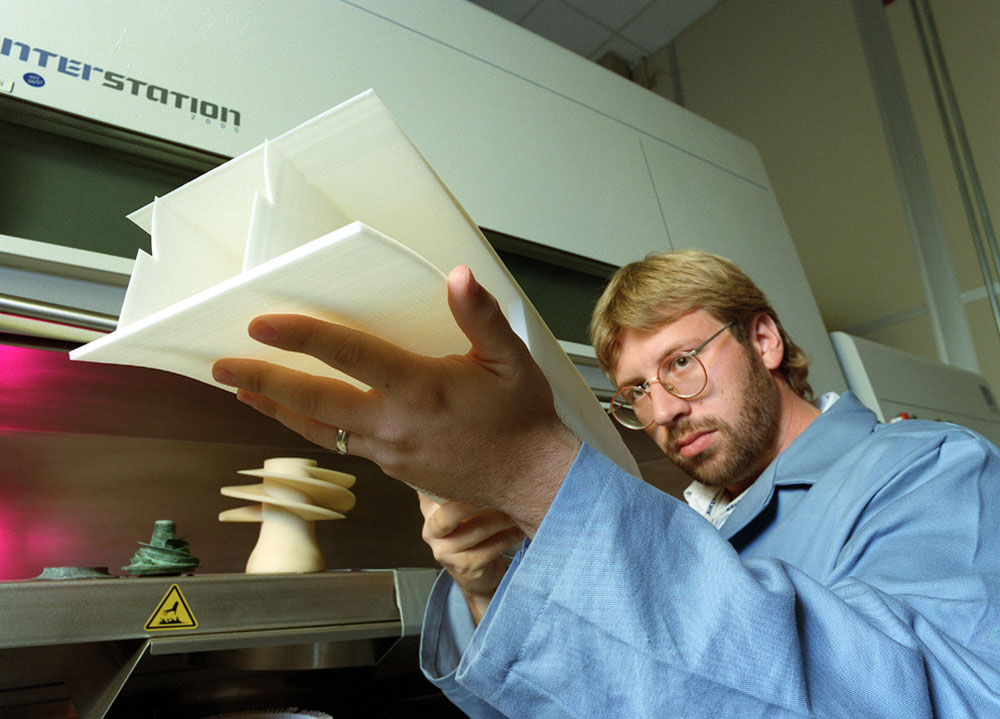

Example: Meeting the Supplier

On a recent visit to one of our suppliers, I had the opportunity to meet with some key employees and thank them personally for the fine work their people were doing in building hardware for one of our missions. Everyone I spoke with gave me confidence that we had made the right decision in choosing this supplier for the job. We toured the plant and I was able to witness first hand the dedication of the employees in providing NASA with a quality product. Following the tour, management arranged for me to speak at a gathering that included nearly everyone in the company. The employees listened intently as I spoke, and I noticed several of them smiling as I praised their work and the important contributions they were making to NASA. Afterwards I shook hands and spoke with several of them individually. It was my pleasure to listen to them talk about their work and how proud they were to be involved with NASA. I thanked each and told them that coming here and getting to know them like this was truly the highlight of my trip.