By Karen M. McNamara

When I started at NASA, I never dreamed of being responsible for the science preservation and recovery of a mission, let alone something that even NASA had never attempted before. I didn’t expect the assignment as Johnson Space Center mission lead for Genesis to come just two months after I’d located my new office in Building 31. And I didn’t expect to be asked to take up Stardust immediately on the heels of Genesis. But it happened, and I accepted both. The first—with its reentry problem—was a dramatic, heart-wrenching experience. People have penned volumes about what should, could, and may have been learned from the Genesis experience. Thankfully, I haven’t been asked to add to that lot. In fact, I want to shift the focus here away from “lessons learned” to a consideration of what I call “planning for learning.” That concept can be understood by examining the circumstances of the Stardust sample-return capsule and, more specifically, its heat shield.

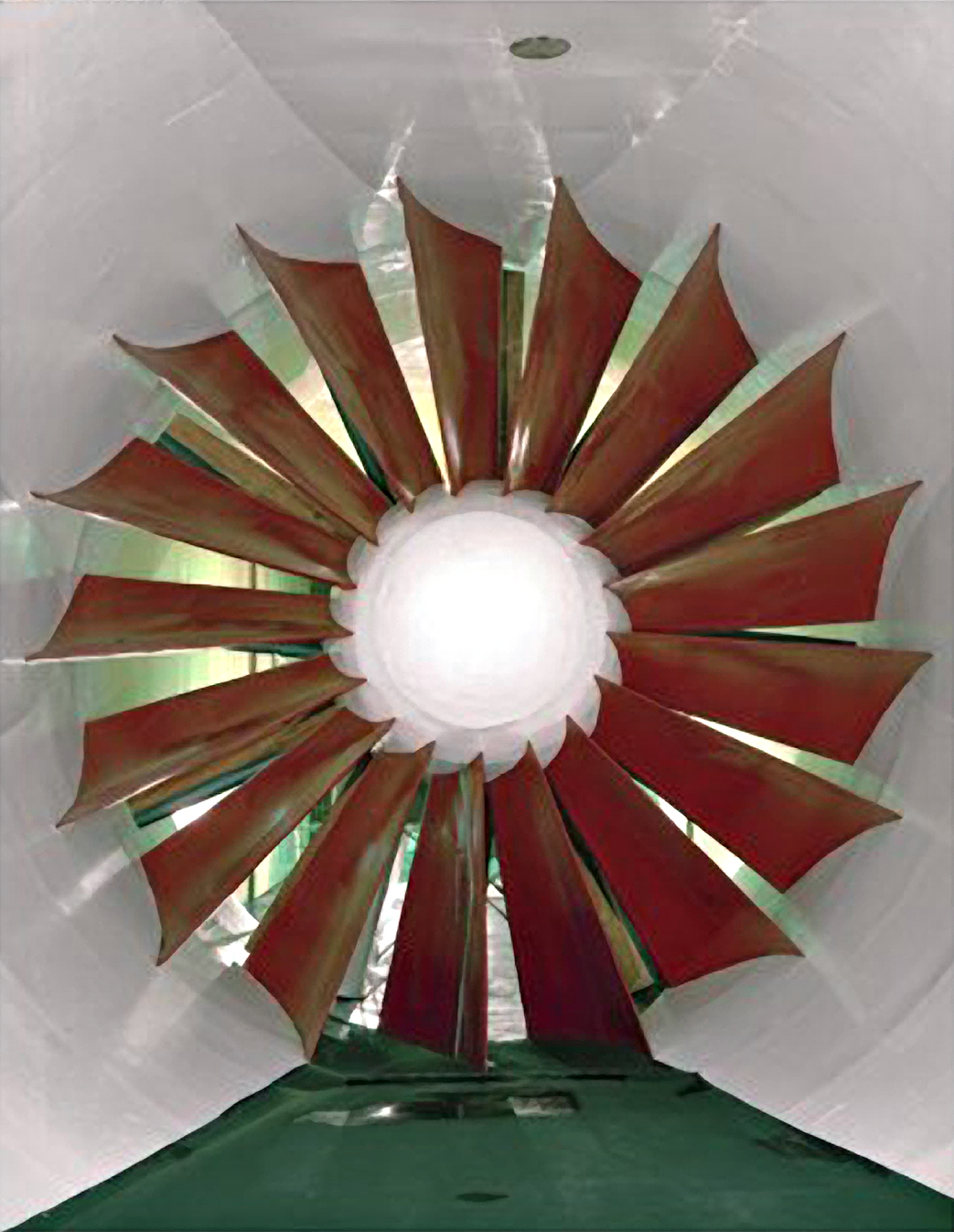

In early 1999, NASA’s Stardust spacecraft was launched on a seven-year mission to collect interstellar dust and materials from Comet Wild 2 and return the samples to Earth, where they could provide information about the early evolution of the solar system and the composition of comets. In 2006, the capsule containing this precious cargo entered the atmosphere at just over 28,000 mph, the highest reentry speed of any man-made object. At peak heating, the nose of the heat shield was required to withstand temperatures as high as 2,500°C. It was one of the most amazing sights I have ever seen. The shield was made of Phenolic Impregnated Carbon Ablator, or PICA. Developed at Ames Research Center, the material won the 2007 NASA Government Invention of the Year award in recognition of its performance on the Stardust mission. In addition to its ability to effectively manage the effects of high reentry temperatures, PICA is much lighter than the Avcoat shield used on Apollo spacecraft.

NASA’s Stardust sample-return capsule is seen with heat shield intact after it successfully landed at the U.S. Air Force Utah Test and Training Range.

Photo Credit: NASA

Given its performance and light weight, PICA has tremendous promise for use on other spacecraft. It is a potential boon to engineers who always struggle to limit the mass of their designs. These characteristics made it an early candidate for heat protection on the new Orion crew capsule. After considerable study, the Thermal Protection Systems Advanced Development Project at Ames recommended Avcoat over PICA for the Orion heat shield because significant technology development was required before the successful implementation of PICA could be assured. Specifically, the large size of the Orion capsule would preclude using one solid PICA casting for the heat shield, as was done on Stardust. The added complexity of casting PICA in sections and developing adhesives that could meet the thermal and mechanical requirements of reentry were identified as important long-term goals, but the risk that additional development posed to the Orion project cost and schedule was too great.

Still, it has been acknowledged that PICA does have a promising future in spacecraft design. (It is scheduled to fly on the Mars Science Laboratory mission in 2011.) The Stardust mission provided an opportunity to develop good technical data that could have supported the use of the material on Mars Science Laboratory and future missions. In some regards, it was an opportunity we missed. After reentry, the Stardust heat shield was in fact carefully retrieved, preserved, and studied in great detail. One of my many unexpected responsibilities at NASA was to “curate” the returned Stardust spacecraft hardware. In that role, I was able to schedule the postflight analyses in the order of least-to-most destructive—in effect, planning for learning.

There was and is much we can learn from the study of the Stardust heat shield and capsule. Unfortunately, the information we could obtain from it was incomplete because detailed, accurate measurements of its thickness and surface characteristics were not obtained before flight. The preflight verification test for shield thickness consisted of micrometer readings taken at only two points on a shield 89 cm in diameter. This was sufficient to ensure adequate performance but not to get reliable information on recession (the amount of material burned away during reentry), which of course requires accurate data about the original as well as the final thickness of the shield.

Not Part of the Mission

Why wasn’t that potentially valuable preflight analysis done? Simply because learning about the performance of the shield was not part of the mission plan. Stardust was a science mission under the Discovery Program. Budgets and schedules for such missions tend to be tight, and no time or money was set aside for research or engineering endeavors external to the scope of the mission. No one had responsibility for that kind of learning.

NASA Ames researchers at the Johnson Space Center curation facility with the recovered Stardust sample-return capsule heat shield.

Photo Credit: NASA Ames Research Center/Dean Kontinos

About a year before launch, people from NASA’s thermal-protection community did suggest that the Stardust team install active instrumentation on the shield so they could monitor PICA’s performance. If they had made their request years earlier and the instruments had been built into Stardust’s design, budget, and schedule at the beginning of the project, it probably could have been done. But at that late date the added cost and time it would have required were not available, and the risk of adding mass, complexity, and making design changes so close to the launch date was unacceptable. Not adding instrumentation was the right call by mission management. But even low-cost, no-risk data gathering (for instance, photographing the shield to have a record of its surface characteristics) was not done before flight. No one thought of doing that or had the responsibility to see that it was done.

Project teams sometimes are responsible for capturing lessons learned at the end of missions; sometimes a small fraction of the budget is set aside for that mission requirement. Those lessons have great value, but the learning they provide is retrospective and often reactive. Postmortem reflection misses important knowledge that could be gained by planning for learning at the start of missions. The key to such planning is to ask and answer the relevant questions—What can we learn from this mission that could be useful to future programs? What do I wish I knew now?—early on and then devote thought and resources to the task of devising the technologies and processes that would make that learning possible. In the case of Stardust, for instance, that would have meant doing better preflight heat shield measurements.

An Office for Planned Learning

I have already mentioned an important reason this does not happen: people understandably focus on their primary mission and devote their limited time and resources to ensuring its success. Another factor is that team members often lack the broad perspective needed to understand which elements of their projects might provide knowledge that other programs would find valuable. They may not even know what missions are being planned at other centers under the auspices of other mission directorates. (Stardust was, of course, a Science Mission Directorate project; Orion is part of an Exploration Systems Mission Directorate program.) Orion’s high visibility means that probably everyone at NASA knows about it; the Stardust thermal-protection system team would be excited to share what they learn with Orion. But most project team members are not likely to spend much time thinking about how they can contribute to another mission directorate’s program. They already have to contend with too little time and money!

What we need, I believe, is an Office for Planned Learning (OPL): a new small organization at NASA Headquarters that has a global overview of past, current, and future work throughout the agency and is responsible for supporting the development of program knowledge that can benefit other programs, projects, or directorates. This would be more rigorous than so-called “cross-pollination,” which assumes the transplanting ideas or individuals will somehow ensure that valuable knowledge is preserved and shared. This office would be responsible for detailed knowledge of organizational and program technologies, with the ability to synthesize the detail into a larger image of the agency and its goals.

Selecting missions and programs where enhanced technology potential warrants increased mission or program investment requires calculations about the potential value of the learning and the risk to mission cost, schedule, and success. Where that calculation favored an investment in learning, OPL would provide financial support and a dedicated liaison to help the program build learning-related activities and technologies into its initial project goals, schedule, and budget. Of course, this needs to be done in the earliest phases of mission development. The kinds of things that did not happen on Stardust because they were “no one’s job” would happen because they would be the shared responsibility of the OPL liaison and designated project team members. Planned learning would become one of the project’s explicit requirements.

Good communication between the agencywide office and individual programs and projects would be essential to make this work. People working within projects would be the source of information the office needs to develop its perspective on what knowledge will have broad value. Once the office synthesizes and prioritizes these opportunities, it will be OPL’s responsibility to communicate that perspective to the project teams to make clear why the knowledge-gathering activities are worth their time and effort. Some of the communication from project teams may be appropriate “pushback” to establish the limits of learning-work that might threaten the mission’s success. It is likely that such an office would have a small full-time staff and numerous rotational openings to provide the most timely infusion of technology awareness both within the programs and within the office.

In a perfect world, there would be would be enough money and time to make planning for learning an important part of almost every NASA project. We don’t work in that world. We will continue to miss some learning opportunities because we lack the resources to take advantage of them. But I believe the kind of attention to learning I have described here will repay our investment in it many times over. Planning for learning early in the lives of our projects and programs can produce knowledge that will contribute to the success of our most demanding and ambitious future missions. Planning for learning is proactive, and proactivity is critical to the success of our mission at NASA.