By Randall Taylor

In December 1996, a Delta II rocket launched the Mars Pathfinder spacecraft.

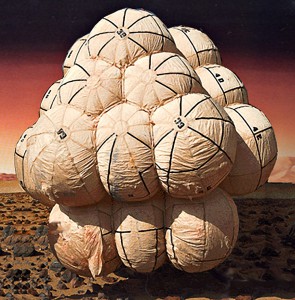

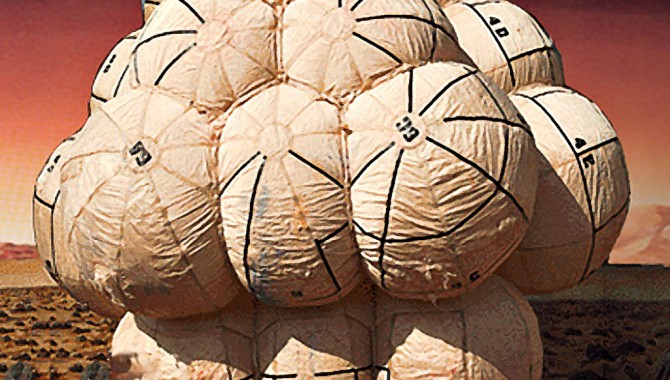

Seven months later, the Pathfinder lander, slowed by parachute and retrorockets and protected by a cluster of airbags, came to rest on the surface of Mars and released a 23-lb. rover that included cameras and a spectrometer for analyzing the Martian soil.

It was not the first time NASA had successfully landed a spacecraft on the planet. More than twenty years earlier, the Viking program had put two landers on Mars. But Pathfinder got there for a tiny fraction of Viking’s cost. After a teleconference with Wes Huntress, during which NASA’s Associate Administrator for Space Science approved Phase B mission planning, project manager Tony Spear said, “That was Wes. He asked me for a Mars lander for Discovery money. I told him yes. Now we have to figure out how to do it.”

As the second mission in the agency’s Discovery program of low-cost space science initiatives, Pathfinder was approved for Phases C and D (design and development) at a maximum of three years and $150 million to do the spacecraft development work. ($25 million was separately provided for the micro-rover development, and the launch vehicle was supplied by NASA, so the total project life-cycle cost was $250 million.) Going over budget was not an option; if Pathfinder couldn’t be built for that amount of money—a congressional cost cap—it would be canceled.

We Are the World

Spear’s plan was to keep a full 50 percent of the budget in reserve to deal with the inevitable surprises and adjustments the ambitious new technology program would bring with it. He was immediately forced to reduce that to 40 percent when news came that residual hardware from Mars Observer would not be available, due to that mission’s failure and the reallocation of flight spares to the new Mars Global Surveyor project. Then there were the added requirements: two unfunded mandates. The budget would have to pay for a public-outreach program and a technology-transfer program. And—yes—let’s not just land on Mars; please build a rover that can move on the surface, photographing and analyzing its surroundings. (The additional money provided for the rover did not fully account for accommodation costs on the spacecraft.) Finally, there was even a Level 1 requirement to create a “new way of doing business” for NASA, part of NASA Administrator Dan Goldin’s Faster, Better, Cheaper directive, which we took very seriously.

Under those circumstances, figuring out how to do it meant adopting a dramatically anti-not-invented-here approach. Spear was ready to find partners anywhere and learn from anybody who could offer assistance. The Pathfinder team talked to the Department of Defense about parachutes and Volvo about airbags. We met with the Russians. We talked to Viking people. (Jim Martin, Viking’s project manager, was on Pathfinder’s review board.) We learned Apollo-era wisdom from Max Faget. We worked with two German institutes, the Danes, and other NASA programs in progress at the time.

Some of these working relationships demonstrated the generosity and flexibility of others and Spear’s skillful management of the human dimensions of cooperative work. The Cassini program, which would launch a spacecraft to Saturn in 1997, bore the full cost of engineering and building the Deep Space Transponder; Pathfinder bought flight units at lower recurring-cost prices.

The Niels Bohr Institute of Denmark supplied the project’s magnetics experiment. One of Germany’s Max Planck Institutes helped build the alpha proton X-ray spectrometer, to be carried by the rover. The German hardware was in the trunk of a taxi that had an accident en route to their partner, the University of Chicago; fortunately, the flight unit survived intact. A second Max Planck Institute supplied detectors for the lander camera. Unfortunately, the camera builder destroyed the flight detectors. A second set was furnished at German expense (we couldn’t pay for it due to NASA’s no-exchange-of-funds policy); these, too, were ruined. Luckily, the third time was the charm. Our foreign partners performed with technical excellence and good grace.

Build a Little, Test a Little, Wreck a Little

People mattered, and process mattered. Tony Spear; Brian Muirhead, the spacecraft manager; and Donna Shirley, the rover manager, assembled a team that Tony described as a mix of “scarred veterans and bright, energetic youth.” Old dogs were taught new tricks, and the next generation of robotic space developers learned from them. We did concurrent engineering (helped by advice from Lockheed’s Skunk Works). We streamlined the procurement process. We partnered with Safety and Mission Assurance on a Class A test program and short-cycle documentation approvals.

To develop the supersonic parachute that would operate in the thin Martian atmosphere to slow Pathfinder during its descent, Pathfinder drew on the Department of Defense’s experience of learning by doing. NASA projects typically go through preliminary design, final design, build, procure or fabricate, assemble, and test. In contrast, the Department of Defense’s parachute programs involved building prototype parachutes, dropping them, and redesigning based on their performance. This proved an effective way of coming up with a design for Mars. What became known as “Desert Splat”—a notable parachute failure—helped point the way to eventual success.

Ingenious public relations helped defuse some potential problems. The contractor doing parachute work for Pathfinder discovered that a ballast rock lost during one drop in Connecticut had lodged in a farmer’s pickup truck. They mollified the victim of the accident by not only paying for repairs to the truck but agreeing to do a flyover and festive balloon drop at the farmer’s daughter’s birthday party.

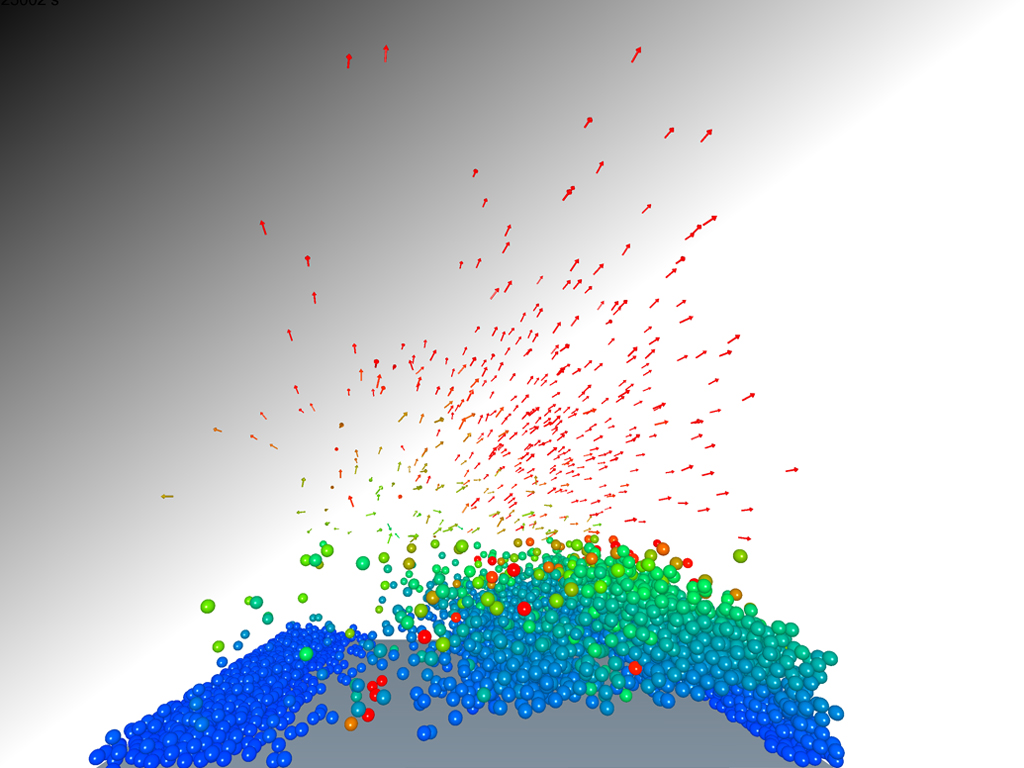

We had to invent how to crash-land on Mars, something never done before. The development process was guided by an interdisciplinary entry, descent, and landing team that included all the major players (NASA centers, federal agencies, industry, small business, and consultants) and frequently evaluated progress.

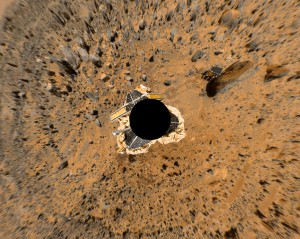

This 360-degree panoramic view was created using several images taken by Pathfinder’s IMP camera. The images were later stitched together to create this bird’s-eye view; the black circle is a result of the camera’s limited field of view atop Pathfinder.

Image Credit: NASA/JPL

Pathfinder had more than one hundred peer reviews. These involved spacecraft subsystems, the payload, and crosscutting systems. The spacecraft manager chaired some of the rover peer reviews and the rover chief engineer chaired several of the spacecraft reviews. Reviews began early in the project. For example, one review compared a tethered rover design to an untethered one. These internal reviews provided a second set of eyes at key points in the project development. They were supplemented by six incremental delivery demonstrations, which forced the various project systems to play together early; the most famous occurred at the non-advocate review/preliminary design review, when the NASA Independent Review Board chair, Jim Martin, walked into the Jet Propulsion Laboratory (JPL) ground data-system area and had his picture snapped by the University of Arizona’s engineering model lander camera. The pixels were sent through a Deep Space Network simulator, and his profile showed on the ground-system workstations before he exited the room.

Cost Control Is a State of Mind

Bringing the project in on budget meant that everyone working on Pathfinder— scientists and engineers as well as managers—had to be cost-conscious all the time. Because every element except the flight system was individually cost-capped by the project manager, groups working on project elements knew what they had to work with: there was no pot of general project money to draw on if they overspent; all reserves had to go toward the spacecraft.

One effect of this budget clarity was to eliminate competition among the groups—there was no extra money to compete for. That and the shared goal of a successful Mars mission fostered valuable cooperation.

One team whose subsystem had to locate the sun found that a sun sensor would be too expensive. Echoing Spear’s anti-not- invented-here ethos, the team lead, David Lehman, said, “I can’t solve this in my area, so we’ll have to get help.” The team approached the lander camera group about using that instrument to find the sun and transferred funds to them to pay for camera software routines that would meet the need.

Similarly, when the power team could not afford the caliber of solar cells they wanted, Allan Sacks, the ground data systems manager, told them, “I’ll give you the $100K you need for better cells because that will make operations less complicated for my team.”

Faster, Better, Cheaper

John Casani, the head of JPL’s Pathfinder review board, made a bet with Spear that the avionics subsystem would not be delivered on time and on cost. It came in on budget and one day early, and Casani had to pay up, delivering two cases of wine to the project celebration at the subsystem manager’s (Lehman’s) home.

“Faster, better, cheaper,” the mantra of that era, has been criticized for demanding too much for too little. We can point to cases where trying to accomplish ambitious goals with severely limited funds probably contributed to failure. Pathfinder is a faster, better, cheaper success story. Discipline, determination, teamwork, and openness to any and every source of expertise and assistance made the difference—a lesson for any project.

For more information, see 2007 IEEE paper, “Ten Years After: Enduring Lessons Learned from Mars Pathfinder,” available from the author.

Note: This work was carried out at the Jet Propulsion Laboratory, California Institute of Technology, under a contract with the National Aeronautics and Space Administration. © California Institute of Technology. Government sponsorship acknowledged.

About the Author

|

Randall Taylor was the procurement manager for the Mars Pathfinder project. He has worked at the Jet Propulsion Laboratory since 1979, with current assignments as project acquisition manager/review captain on the GRAIL project and project manager of the Acquisition Reengineering project. |