By Carol Anne Dunn, Carlos Calle, and Richard LaRoche

To learn more about managing lunar dust, NASA and a simulation technology company pool their expertise.

A major problem facing manned or unmanned missions to the moon is lunar dust.

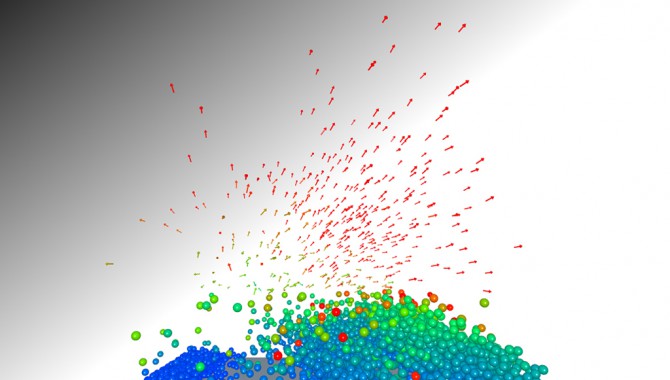

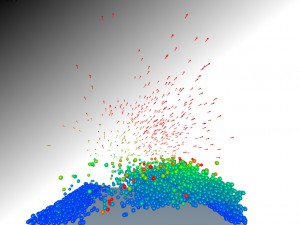

EDEM simulation of dust particles being removed from a dust screen under the influence of an electric field.

Image Credit: DEM Solutions

Dr. Carlos Calle, founder and director of the Electrostatics and Surface Physics Laboratory at Kennedy Space Center, is familiar with the problem. He has carefully reviewed Apollo mission reports and debriefings to familiarize himself with problems encountered during those missions. The Apollo astronauts had limited visibility during descent due to dust effects, and NASA was uncertain how the astronauts’ health would be affected as they inhaled and ingested the dust. During the Apollo 15 mission, a camera failed because highly abrasive dust entered the drive mechanism.

Lunar dust is thought to be electrostatically charged, which would make it difficult to remove from solar panels, viewports, camera lenses, and astronaut suits, gloves, and visors. Similar problems would be encountered on the dusty surface of Mars. With possible missions to the moon to try out enabling technologies for Mars exploration, scientists like Calle are concerned for a number of reasons. We would be staying longer on the surface than the Apollo astronauts; future missions may include dust-raising activities, such as excavation and handling of soil and rock; and we would be sending robotic instruments to do much of the work for us.

Understanding more about the chemical and physical properties of lunar dust, how dust particles interact with each other and with equipment surfaces, and the role of static electricity build-up on dust particles in the lunar environment is imperative to developing technologies that can remove and prevent dust accumulation as well as successfully handle regolith, also known as lunar soil. Calle is currently working on the problems of the electrostatic phenomena and is involved in developing instrumentation for future planetary missions.

The Electrostatics and Surface Physics Laboratory performs research and development on technologies that can assist operations at Kennedy and at other NASA centers to detect, mitigate, and prevent electrostatic-charge generation and discharge on spaceflight hardware, ground-support equipment, International Space Station modules, and payloads.

“We are particularly excited about our work on the Electrodynamic Dust Shield,” said Calle. “We first worked with the University of Arkansas at Little Rock to mitigate and prevent the accumulation of dust on solar panels for Mars missions.” Every fifteen months to three years, Mars is engulfed in a dust storm that can last for months, and every day there are dust devils, tornado-like columns of spinning dust. The project is now part of the NASA-wide Dust Management Project. Even though NASA is not planning on manned moon missions, the lab expects there to be unmanned lunar missions where this technology for preventing and removing surface dust will be important.

To further this research, Kennedy’s Innovative Partnerships Program (IPP) Office partnered with DEM Solutions, Inc., a global leader in particle-dynamics simulation software, after NASA personnel made a seed fund proposal to IPP. Customers in pharmaceutical, chemical, mineral, and materials processing industries as well as oil and gas production, agriculture, construction, and geo-technical engineering use DEM’s EDEM software to improve the design and operation of equipment that comes into contact with particulate material.

EDEM can simulate and analyze particle handling and manufacturing operations, which allows users to create a model of any granular-solids system. Computer-aided design models of real particles can be imported to obtain an accurate representation of their shape. In addition to particle size and shape, the models can account for physical properties of particles along with interaction between particles and with equipment surfaces and surrounding media. The flexibility and extensibility of the software enables simulation of granular materials from powders to gravel. In order for the software to simulate regolith, however, additional modeling and validation of electrostatic and surface-energy adhesion forces, dynamic friction, and particle shape were required.

DEM Solutions was able to use previous experience working closely with NASA scientists to develop custom solutions for modeling the effects of electrostatic forces on particles. The NASA scientists provided a theoretical framework for introducing the electrostatic force component to the software, and DEM engineers developed the computer code that implemented it.

The new proposal enhanced the existing EDEM software to provide more accurate modeling of lunar dust and regolith—with the potential to improve design quality and provide significant savings, especially in respect to field testing. “We wanted to build on off-the-shelf software, and the user-friendliness and range of capabilities in EDEM made it attractive. The experience of the staff at DEM Solutions in modeling complex particulate systems such as [those] encountered in space applications gave us the confidence that they would be a strong partner,” said Calle.

Once the work was under way, NASA provided a simulation that had been developed earlier for the study of electrodynamic dust-shield technology. DEM Solutions incorporated that simulation into EDEM and developed a more complete simulation of the dust shield in action. This early implementation not only served to show that the theoretical framework and the computer code were correct, but also provided NASA with a tool that could be used immediately.

Most of the technical work was performed by David Curry, a senior consulting engineer at DEM Solutions in Edinburgh, and Michael Hogue, of Kennedy’s Electrostatics and Surface Physics Laboratory. To ensure that work remained focused and moving in the right direction, regular web-based conferences were used to share results and discuss ideas for extending the modeling capabilities. In addition, Curry visited Kennedy near the end of the project to work directly with Hogue to provide training and transfer knowledge about the technology developed in EDEM.

“The NASA IPP project enabled us to extend the capabilities of our EDEM particle-modeling software for NASA’s applications,” noted Richard LaRoche, vice president of engineering and U.S. general manager of DEM Solutions. “But this project also spawned innovations resulting in advanced features that our current customers now use for modeling cohesive materials and particle-fluid systems.”

The DEM Solutions partnership provided NASA with expertise in particle-dynamics simulation and a custom computer-aided engineering tool that supported initiatives in the Exploration Science Mission Directorate’s Exploration Technology Development Program, particularly in dust mitigation and in situ resource utilization, modeling the behavior of the dust as it came into contact with an electrodynamic dust shield. Other simulations now augment the development of other NASA dust-mitigation technologies, such as those designed for dust removal and cleaning optical and thermal radiator surfaces, connectors, and seals.

To help create accurate simulations, Kennedy’s Electrostatics and Surface Physics Laboratory and Glenn Research Center’s In Situ Resource Utilization Lunar Regolith Characterization Laboratory identified the correct physics to add to the EDEM code. Glenn researchers Allen Wilkinson, Enrique Rame, and Al DeGennaro shared abstracts of relevant research papers from their on-site NASA Exploration Soils Bibliographic Database Resource. Using this information, DEM Solutions engineers proposed several approaches for the lunar-soil particles that could be integrated into existing EDEM software without significantly slowing down the simulation or unnecessarily increasing user inputs.

One challenge was calibrating the new EDEM model to obtain the right lunar-soil parameters. The teams decided to run a laboratory experiment—the Schulze shear test—with lunarsoil simulant and then simulate the same experiment in EDEM. Enrique Rame from the National Center for Space Exploration Research in Fluids and Combustion at Glenn ran the lab test and provided DEM with the operational parameters and results. Philip T. Metzger from the Granular Mechanics and Surface Systems Laboratory at Kennedy provided additional information on lunar-soil particle-size distribution. This information was used to create an initial model for lunar soil and then to run simulations with different EDEM parameters to identify the best input parameters.

These new EDEM capabilities can be applied in many industries unrelated to space exploration, and they have been adopted by several U.S. companies, including John Deere, Pfizer, and Procter & Gamble.

Carol Plouffe, an engineering manager working for John Deere, said, “The goals of the project are of great interest to John Deere since we have similar objectives as NASA in terms of being able to build reliable models of bulk particulate behavior and are users of EDEM software. Most of the agricultural and construction machinery developed by Deere involves the movement of bulk material. By developing the capability to model regolith, which is a fine material with angular particles and cohesive properties, the project is likely to solve some of the modeling challenges we face on Earth with cohesive or sandy soils.”

This project benefited all involved and shows that NASA’s IPP Seed Fund can help both the space program and other U.S. industries. Working together with external partners contributes to NASA’s ability to help stimulate the economy and provide solid answers to difficult problems.

Special thanks to DEM Solutions for their help in writing this article. For more information, visit www.dem-solutions.com. For questions regarding NASA’s Innovative Partnerships Program Seed Fund, contact Alexis Hongamen.

About the Authors

|

Carol Anne Dunn currently works as a project specialist within the Engineering Management and Integrated Services Branch at Kennedy Space Center. She is also the awards liaison officer for the Inventions and Contributions Board. | |

|

Carlos Calle is a senior research scientist and the founder and director of the Electrostatics and Surface Physics Laboratory at Kennedy Space Center. | |

|

Richard LaRoche is vice president of engineering and U.S. general manager of DEM Solutions. |