Tracking and Data Relay Satellite-K, enclosed in its payload fairing, passes through the Launch Complex 39 area and Vehicle Assembly Building at Kennedy Space Center as it travels from the Astrotech payload processing facility to its launch site. Photo Credit: NASA/Glenn Benson

By Stefano Coledan

Two months shy of the thirtieth anniversary of the first Tracking and Data Relay Satellite (TDRS) launch, the eleventh in this group of NASA spacecraft successfully flew into orbit January 30, 2013, aboard a United Launch Alliance Atlas V rocket.

The NASA and United Launch Alliance launch teams monitor the countdown before the launch of the Tracking and Data Relay Satellite-K spacecraft on an Atlas V rocket. The teams work inside the Atlas Space Operations Center at Cape Canaveral Air Force Station, Fla.

Photo Credit: NASA/Kim Shiflett

The TDRS-K lifted off Launch Pad 41 at Cape Canaveral Air Force Station at 8:48 p.m., lighting up the evening sky in a golden display of fiery power. This latest version is the first of a new generation of communications and data-relay satellites. Built by Boeing, the 3,700-lb. satellite is a heavier, more sophisticated, and more powerful descendant of the spacecraft making up the original network. “TDRS-K will handle amounts of information up to five times larger than its predecessors,” says TDRS-K Program Manager Jeffrey Gramling.

A successful liftoff is a fundamental step in the climb to Earth orbit. Just as vital, however, are the services preceding, supporting, and following every launch—all the way from pre-mission planning through launch vehicle–spacecraft separation to the end of the spacecraft’s useful life.

NASA’s Launch Services Program (LSP), established in 1998, is deeply involved in every step of this process. It brings a half-century of launch experience and expertise, along with state-of-the-art technology, strategic planning, business, procurement, and engineering best practices to every mission. LSP strives to facilitate and reinvigorate America’s space effort, broadening the unmanned rocket and satellite market by providing reliable, competitive, and user-friendly services.

It’s no exaggeration calling the LSP Earth’s bridge to space—a bridge standing on four pillars representing the LSP goals:

- Maximize mission success and achieve mission excellence for all missions.

- Ensure long-term launch services by providing end-to-end and advisory service expertise for NASA science, exploration, U.S. government, and government-sponsored missions.

- Promote evolution of a U.S. commercial space launch market through continued relationship development with customers and stakeholders as well as the continual enhancement of policy, contracts, and launch products and services.

- Continually enhance LSP’s core capabilities by monitoring the program’s performance-assessment tools and measures, relationships with customers and stakeholders, workforce, LSP policy and contracts, and services.

Anatomy of a Launch

The successful launch of TDRS-K was the fulfilling conclusion of an effort dating back seven years—average for a process that normally takes between four and ten years. TDRS-K’s trip to orbit began with LSP’s pre-mission planning, mission planning, and mission baseline phases. These phases take into account the customer’s needs and requests and define the support required and technical guidance needed for each unique mission. The main task is helping the customer choose what launch vehicle best fits the satellite for an acceptable price.

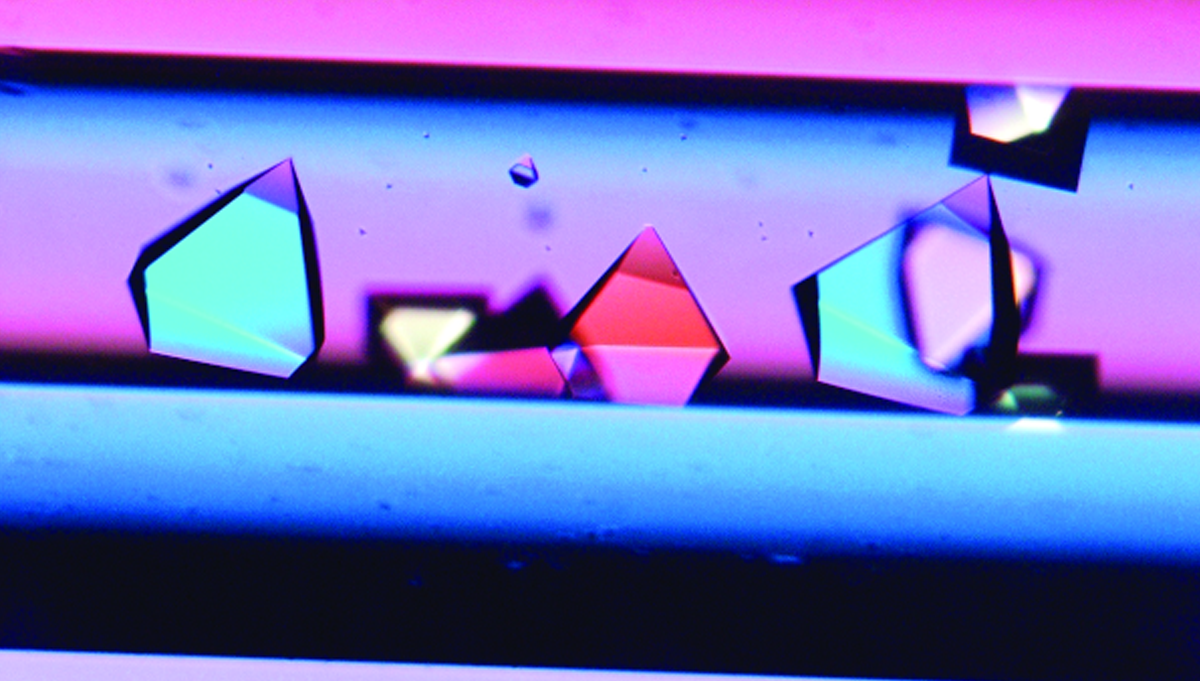

Technicians inspect the payload fairing placed over Tracking and Data Relay Satellite-K inside the Astrotech payload processing facility near Kennedy Space Center.

Photo Credit: NASA/Tim Jacobs

When the mission has been defined with clear enough requirements to proceed with purchasing the launch service, it’s up to NASA’s Flight Planning Board to give the green light to procure the launch service.

Launch Vehicle/Spacecraft EngineeringManufacturing Phase

Once a mission is formally manifested through NASA Headquarters’ Human Exploration Operations Mission Directorate’s Flight Planning Board, the mission transitions to a permanently assigned mission integration team, providing consistent LSP involvement from the earliest mission concept studies to the final countdown. Mission integration working group meetings and ground operations working group meetings are held at regular intervals throughout the launch campaign. The first major goal in this phase is to develop and coordinate the mission’s interface control document, followed closely by the safety package for range safety and the launch-site support plan for launch-site processing. Data exchanges support analysis in areas including thermal, clearance, separation, environment, and trajectory. These analyses are reiterated throughout the launch process.

Launch-Site Operations and Launch Campaign

Typically, sixty to ninety days before launch, a spacecraft arrives at the launch site for stand-alone processing. Activities include post-shipment testing, fueling, and spin balancing, if required. The launch vehicle will be erected and tested in the vertical integration facility before it is moved to the launch-pad a day or two before launch. At the conclusion of spacecraft processing, the spacecraft is encapsulated and moved to the pad for mating operations and integrated testing.

United Launch Alliance Atlas V 401 rocket with its NASA Tracking and Data Relay Satellite-K payload races above the lightning masts on Space Launch Complex 41, leaving plumes of exhaust and smoke in its wake.

Photo Credit: NASA/Tony Gray and Robert Murray

In mid-January, across the Indian River from the Kennedy Space Center, some thirty engineers and technicians worked in the privately owned Astrotech payload processing facility (PPF). Inside the spotless workroom, they put the finishing touches on the $400-million TDRS-K so it could fit into the protective fairing of the Atlas. Total cost for the rocket, launch services, and other operations under different contracts amounted to $123.9 million.

According to Diana Calero, NASA’s LSP mission manager for TDRS-K, “Regardless of how many times one enters the PPF or a similar ‘clean room’ to check out a spacecraft, there is always an element of surprise. You always have a sense of awe when you walk in and see this big spacecraft that’s so intricate and so technologically advanced. Entering the PPF gives you pause. You look at this spacecraft and just let the greatness of what’s about to be launched sink in. There’s definitely that feeling of awe, and also of pride, sending this spacecraft 22,300 miles above Earth to have it carry out all the work it’s designed for.”

Launch Management

The launch management phase concludes with the launch readiness reviews—the final opportunities to close out technical, timetable, and operational requirements. Once these activities are complete, the green light to start final launch preparations comes on. “We are a very process-driven organization,” said Launch Director Tim Dunn. “Part of my responsibility is making sure, as we enter a launch campaign for a specific mission, that all of our processes are being implemented. During the countdown, in my role as launch director, I have the final say from NASA as to whether we are ready to launch or not,” Dunn said. “And if we are good to go, I will pass that ‘go’ to our launch contractor, United Launch Alliance, which will execute the final, terminal countdown, taking us down to T minus 0.”

As workers at the pad finished preparing the Atlas V rocket and Centaur upper stage for fueling, most of the discussions were centered on wind speed and gusts. They were still within the safety limits, yet worth keeping an eye on. The launch team at the Atlas V’s Spaceflight Operations Center cleared a handful of minor technical problems on the rocket. As for TDRS-K, it was in perfect health and got mentioned only for a final “go.”

The readiness polls followed, with the final one taking place during the last planned pause in the countdown, holding at T minus 4 minutes. All parties involved responded “go.” Outside, the wind had cleared the sky of any clouds or haze. The stars were shining vividly, and more than one person expressed hope it would be a good omen.

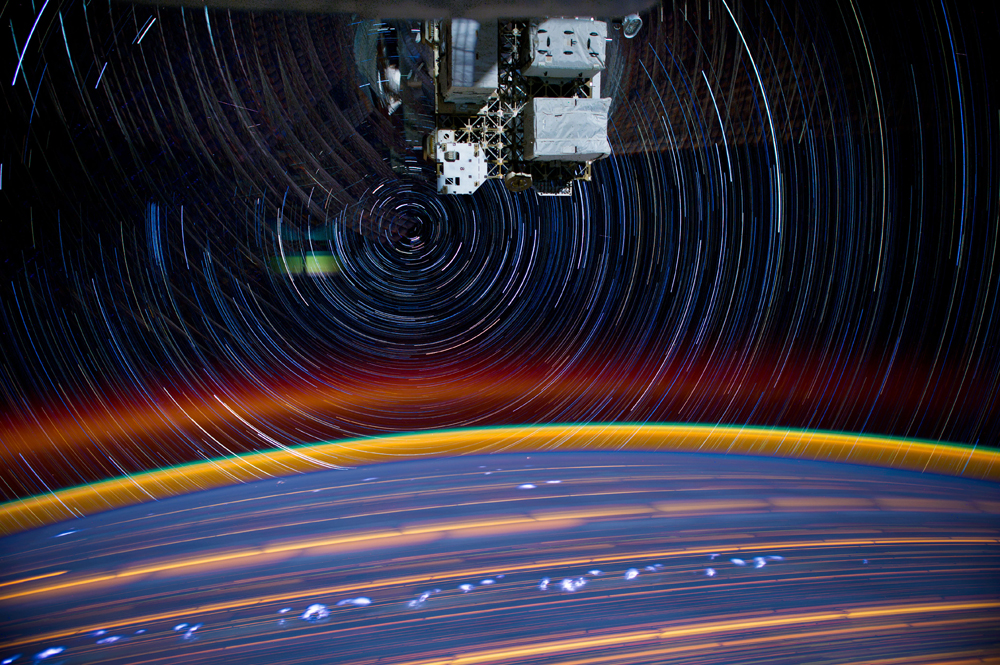

The Launch

Four minutes of propulsion were all it took for the Atlas to consume all its hydrocarbon fuel and liquid oxygen, and finally separate from the Centaur. The upper stage continued its ascent. Data received on the ground showed small pressure oscillations in the liquid oxygen tank, whereas the hydrogen tank remained steady throughout both firings of the upper-stage RL-10 engine. The reason for the phenomenon wasn’t immediately clear, but it had no impact on an otherwise perfect climb to space. One hour and 52 minutes after liftoff, the Centaur released the eleventh TDRS satellite on its path to geosynchronous orbit, 22,300 miles high. Applause broke out in the Launch Control Center and Hangar AE.

Post Launch

The work doesn’t end there. Telemetry data is analyzed for any observations or discrepancies with the launch vehicle performance and spacecraft delivery to the correct orbit is verified. Finally, control is handed over to the spacecraft team for final testing and future use from its geosynchronous orbit.

Tracking and Data Relay Satellite-K, enclosed in its payload fairing, passes through the Launch Complex 39 area and Vehicle Assembly Building at Kennedy Space Center as it travels from the Astrotech payload processing facility to its launch site.

Photo Credit: NASA/Glenn Benson

The pride felt by all directly involved—from managers to engineers, analysts, launch and flight controllers—is palpable. Despite all the stress, the endless meetings and worries, and the overtime, none of them perceive their jobs as drudgery. On the contrary, says Chuck Tatro, mission manager for the upcoming James Webb Space Telescope and Mars Atmosphere and Volatile Evolution missions, “There are lots of days I don’t remember the drive home. I’m just very excited or very deeply in thought about an issue.” He admits, “There are lots of days that you take your work home with you, or you think about it during your drive home. That’s naturally part of what we do because we all like this business so much. We all enjoy launching satellites and missions to other planets. It’s exciting. So you tend to engage more than just from 8 to 5.” Smiling, he adds, “And it’s fun.”

Dunn notes, with obvious pride, “Here at the Launch Services Program, we have some of the best and brightest from across the launch industry here at our disposal. Our technical team, engineers and analysts, have a very large number of years of service.” The average LSP engineer has a service experience that’s generally greater than ten years, Dunn says, but it’s not rare to come across individuals with more than twenty years of launch practice. This high level of competence is of particular significance. In fact, it works like a magnet, as it helps in shaping the LSP of the future. “We’re able to bring in new engineers that are working alongside guys who have been doing the job, and doing it successfully, for twenty to thirty years. It’s tremendously rewarding working with the type of individuals that LSP can attract,” says Dunn.

“We couldn’t do it without a dedicated, professional group of people who are putting a large portion of their lives into this. Even if you have all the procedures, and you’ve done this before, you still need the right people doing this job right,” adds Gramling.

Related Links

About the Author

|

Stefano Coledan has been assisting NASA’s Launch Services Program since 2012 as an a.i. solutions contractor. Besides a journalism degree from Orlando’s University of Central Florida, he holds a metallurgy and mechanical engineering diploma from Polytechnic Institute near Venice, Italy, as well as a State of Florida certification as a science teacher. |