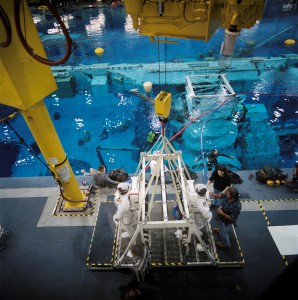

Johnson integrated environments facilities test, evaluate, and certify for spaceflight. The Space Station Airlock chamber was developed to support the International Space Station program for airlock and extravehicular hardware testing, verification/certification, and flight crew training. Photo Credit: NASA Johnson Space Center

By Joyce Abbey

During the Apollo era, the NASA budget peaked at approximately 4 percent of the overall federal budget. Fifty years later, the Cold War is over, there are no more missions to the moon, the Space Shuttle has been retired, the International Space Station (ISS) has been completely assembled, and America’s sights are set on destinations beyond low-Earth orbit. NASA has had to achieve these complex missions with less funding than Apollo, while maintaining a commitment to excellence and mission success. For the past twenty years, Johnson Space Center’s Mission Operations Directorate (MOD) has been working to ensure that their skills, facilities, and standards of excellence remain at the highest level.

The Neutral Buoyancy Lab is a vital training ground for spacewalking astronauts. In this photo, a crew of technicians prepares two astronauts for their descent into the pool.

Photo Credit: NASA Johnson Space Center

What Is MOD?

MOD is responsible for the planning, training, and flight of NASA’s astronauts and human space vehicles. MOD includes the infrastructure required for these activities: the Mission Control Center (MCC), IT architecture, and simulators and mock-ups, such as the ISS training facility, Space Vehicle Mock-Up Facility, and the Neutral Buoyancy Laboratory.

MOD’s mission is to ensure the success of any NASA human spaceflight program, remain stewards of critical human spaceflight technical capabilities, and facilitate flight operations culture. The technical and leadership culture of MOD has survived because of the deliberate transformation the directorate has instigated in the face of increasingly complex mission objectives and static or diminishing budgets.

In 1990, while supporting the Space Shuttle program, MOD’s budget was approximately $412 million and its head count approximately 5,000. By 2010/2011, MOD had the same budget but fewer than 2,500 employees to support shuttle, the continued construction and support of the space station, and the planning and development of procedures for the new Constellation program. With a 50 percent reduction in workforce and a tenfold increase in complexity over the course of twenty years, MOD leadership realized they had to proactively work to sustain a technically sound organization regardless of the external environment.

Developing a Vision

No single event drove the transformation; it evolved out of MOD’s culture of continuous improvement. Texts including Jim Collins’ Good to Great and Built to Last and John Kotter’s Leading Change served as guideposts and led to tough questions such as, “What can we do to continue to raise the bar, but also acknowledge the budgetary environment?” As Jim Thornton, manager of MOD’s Management Integration Office stated, “Recognizing the environment and the programs’ need to constantly squeeze more juice out of the orange fuels the fire for improving, innovation, and efficiency and never being static.”

View of the station flight control room in Johnson Space Center’s Mission Control Center during rendezvous and docking operations between the Soyuz and TMA-3 spacecraft and the International Space Station.

Photo Credit: NASA Johnson Space Center

MOD realized that, as an organization, they were going to have to be leaner and more agile to survive in a future of diminishing resources. MOD leadership identified three major objectives:

- Reduce the cost of their station operations by 30 percent.

- Support Constellation for no more than 50 percent of what it took to fly and support shuttle.

- Restructure mission-related information systems and deploy a state-of-the-art, commodity-based IT infrastructure.

As Kotter makes clear in his book, a transformation effort will fail unless most of the organization’s members understand, appreciate, commit to, and engage in making it happen. MOD leadership’s guiding principle has been to use every existing communication channel and opportunity to explain and support the initiative.

A new publication called the 8th Floor Newsletter (a reference to the location of MOD management offices) was sent to all employees. It provided current information on the shuttle and ISS programs and outlined what was happening strategically inside the directorate. Additionally, facts were presented, rumors dispelled, and answers to hard questions provided at regular all-hands meetings hosted by MOD civil servant and contractor leadership. Understanding that no single communication method would suffice and that it is human nature to resist change, leadership acknowledged the need to repeat the message of this transformation continually, and reiterate that MOD was not changing what they did, but merely how they did it. Effective communication became especially important as MOD made changes to how personnel are trained. (See “Implementing Change” on the following page.)

Although the vision was articulated from the top down, implementation plans were

developed by the boots on the ground. Actively engaging employees was crucial to success and to ensuring a variety of perspectives, so tiger teams of individuals selected from sections of the organization were created. Participants were encouraged to view the organization as a whole. These teams looked at a variety of issues inside the directorate and came up with transformational recommendations. Extending that engagement through the good team relationships with primary contractors brought MOD further cost-saving initiatives. United Space Alliance, MOD’s flight operations contractor, submitted suggested efficiencies. Lockheed Martin, the facilities development and operations contractor, also proposed initiatives to help reduce facility costs. The winner of the Neutral Buoyancy Lab operations contract developed partnerships with industry to assist in offsetting the operational cost of the facility without compromising MOD’s needs.

Johnson integrated environments facilities test, evaluate, and certify for spaceflight. The Space Station Airlock chamber was developed to support the International Space Station program for airlock and extravehicular hardware testing, verification/certification, and flight crew training.

Photo Credit: NASA Johnson Space Center

To counter a widely held misperception within NASA that MOD was too costly and resistant to change, leadership assembled historical data to disprove this belief. Director of Mission Operations Paul Hill met with the deputy NASA administrator to review the funding and facts and explain MOD’s role and responsibilities. NASA Headquarters quickly recognized the directorate as a benchmark for an efficient NASA organization.

Leadership adopted benchmarking to guide plans for change. This process is widely used in industry to spur improvement and change, but trying to find a company or industry that does what MOD does is far from easy. Recognizing this challenge, leadership found industries that do parts of what they do, such as the State of Arizona Control Center for Power Distribution in Phoenix, the New York City Emergency Response Center that was developed after 9/11, and the Schriever Air Force Base 50th Space Wing, which commands satellites. Benchmarking delivered mixed results. Some visits showed that MOD itself is the benchmark—an important validation of the operation. To ensure that benchmarking remains part of the objective for continuous improvement, a new chief engineer position was created to focus on the process. The directorate also implemented a requirement that those in leadership roles complete at least one benchmarking effort each year.

Implementing Change

Making more efficient use of personnel was an important change. For instance, flight controllers and flight instructors were traditionally two distinct groups. New hires brought into the organization were assigned to do either flight control or instructor disciplines. They then had two to five years of training that resulted in a capstone certification as a mission controller or as a full-task simulator instructor. Leadership realized that maintaining separate roles would not be efficient. Naturally, they had to overcome resistance to change. They used the multi-prong approach to communication and stressed that they were not changing what is done, but how it is done.

NASA astronauts Clayton Anderson (left) and Rick Mastracchio, both STS-131 mission specialists, use virtual-reality hardware in the Space Vehicle Mock-Up Facility at Johnson Space Center to rehearse some of their duties on an upcoming mission to the International Space Station.

Photo Credit: NASA/James Blair

In the new approach, new hires are required to learn a scaled-down set of operational responsibilities within a year to eighteen months. Once that initial certification is achieved, the individual proceeds to an advanced flight controller certification, instructor certification, or both. This allows the organization to receive a quicker return on investment, improves the quality of training by providing instructors with operational experience, and reduces organizational overhead by not having to maintain separate groups of flight controllers and instructors.

Whenever a transformation of this magnitude happens, evaluating and managing risk are paramount. MOD chose not to employ a formal risk management process during the transformation, as risk management was already institutionalized within the MOD culture. The underlying theme throughout the transformation was “first, do no harm.” Crew safety, mission success, and the reliability of the facilities were non-negotiable, and the entire organization kept these in the forefront of their minds. As Thornton stated, “MOD will not lower the bar to achieve efficiencies and will not compromise crew safety, mission success, and availability of facilities.” The result of this streamlining effort was well worth the challenges, as the organization was able to find efficiencies, increase the skill and knowledge of employees, and significantly reduce training time while ensuring the safe flight and return of NASA’s human space vehicles and astronauts.

MOD’s facilities are crucial to their mission, from the mock-ups for training to the computers used to transmit data from Mission Control Center to the ISS. These facilities and hardware numbering over 7,500 individual pieces were expensive and required constant maintenance. Due to the advances in personal computing, MOD was able to swap high-maintenance mainframe computers for commercially available hardware and software, which were easily adapted to the needs of the directorate. Furthermore, recognizing that their expertise did not lie in software development, MOD sought out a partnership with Ames Research Center. Ames was able to develop cloud-like computing software to do a portion of the work flight controllers previously did manually. The directorate is now on track to reduce IT equipment by 75 percent by 2015. As Hill stated, “… a number [of] things have come together that point the way for us to do things in the control center, like shrink down our IT footprint to a few boxes compared to a few rooms or an entire floor of a building.” The switch to commercially available hardware and software has also meant a 20-percent reduction in total power usage since 1990, with an additional expectation of a 25-percent reduction over the next three years as more changes are made to the facility architecture.

Hill said, “Within the last two years we have already given back about a third of that commitment to the Space Station Program …. The rest of that 30 percent we are on the path to commit to in our next budget cycle.” As far as the reduction in the cost to plan-train-fly Constellation, Hill stated, “Had we stayed on the path that we were on for Constellation, MOD would be showing up in the official NASA budget with costs no higher than half of what our costs are for equivalent shuttle operations. For the ascent, entry, and orbit operations associated with Orion in test flights and commercial crew services to ISS, MOD is on a path to support with 25 percent or less than our shuttle costs.”

The Coming Commercial Spaceflight Era

Private industry often perceives government involvement as oversight or regulatory, more of a hindrance than a help. Hill stated, “From a government organization perspective … we have to look at the relationship differently in order to appeal to industry to see government as an entity that is here to help. It’s about leveraging those things that are unique about MOD—the real MOD strengths—to ensure the success of whatever the next mission is or missions are. How do we best leverage the things that MOD is responsible for?”

To best position MOD’s assets—the people, facilities, and knowledge—leadership had to come to terms with some hard facts. They realized that this effort was not about preserving jobs or protecting infrastructure, budget level, or workforce. Nor was the goal to turn MOD’s workforce into facility managers leasing space for commercial companies to use. Instead, leadership focused on developing a value proposition regarding MOD’s capabilities and the opportunity to help the commercial space industry.

The directorate found many win–win scenarios. Industry workforce would work directly with flight controllers and instructors who would share their unique knowledge based on fifty years of MOD experience. Leadership expects that not only will industry have assistance in determining how to set up their operations, but that MOD will also absorb some of industry‘s best practices. Commercial partnerships would help maintain MOD’s existing infrastructure—the MCC, mockups, and simulators—while commercial industry could defer or avoid the expense of building these themselves.

Meeting the Challenge

Transformation is difficult, but MOD has shown that it is possible to change while maintaining a dedication to excellence and mission success by paying attention to communication, personnel engagement, benchmarking, and finding efficiencies. Dedication to continuous improvement and efficiency and to developing a plan for partnerships with commercial space providers, MOD has made sure that they will be equipped to meet new challenges and will no longer have to react to every program or objective change. Whatever the next mission objective, they will have the skills and knowledge and facilities needed to achieve it. As NASA transitions from the shuttle era to the era of commercial opportunities and exploration outside low-Earth orbit, MOD will be ready and able to support the future success of human spaceflight.

About the Author

|

Joyce Abbey is the employee communications/external relations director for SAIC’s Risk and Reliability Solutions Division, working in education and community outreach, focusing on employee engagement, and serving as a trusted advisor to NASA Johnson Space Center. She began working in mission operations on the Space Shuttle program at Johnson in 1986 and later joined the Safety and Mission Assurance team in 1990 before moving on to resource management, and organizational planning and development. |