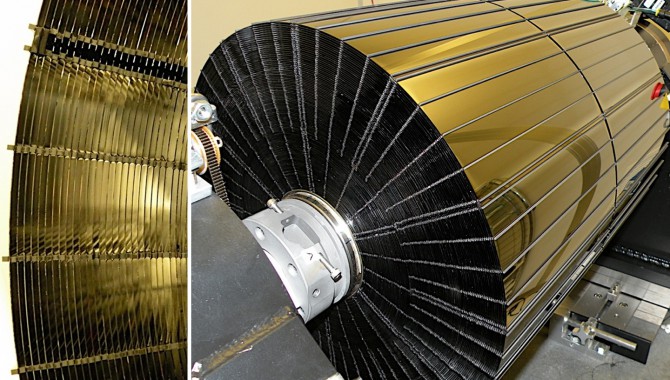

Different views of one of two optic units onboard NuSTAR, each consisting of 133 nested cylindrical mirror shells as thin as a fingernail. The mirrors are arranged in this way in order to focus as much X-ray light as possible. Photo Credit: NASA/JPL-Caltech

By William W. Zhang

Many NASA projects involve designing and building one-of-a-kind spacecraft and instruments. Created for particular, unique missions, they are custom-made, more like works of technological art than manufactured objects. Occasionally, a mission calls for two identical satellites (STEREO, the Solar Terrestrial Relations Observatory, for instance). Sometimes multiple parts of an instrument are nearly identical: the eighteen hexagonal beryllium mirror segments that will form the James Webb Space Telescope’s mirror are one example. But none of this is mass production or anything close to it.

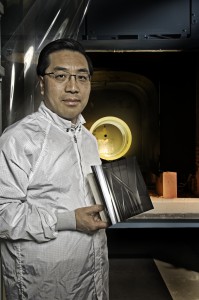

Niko Stergiou, a contractor at Goddard Space Flight Center, helped manufacture the 9,000 mirror segments that make up the optics unit in the NuSTAR mission.

Photo Credit: NASA/Chris Gunn

The mirror segments my group has built for NuSTAR, the Nuclear Spectroscopic Telescope Array, are not mass produced either, but we make them on a scale that may be unique at NASA: we created more than 20,000 mirror segments over a period of two years. In other words, we’re talking about some middle ground between one-of-a-kind custom work and industrial production.

Mirrors for NuSTAR

The mirror segments of NuSTAR’s two X-ray telescopes are made from thin glass sheets coated in alternating layers a few atoms thick with silicon and tungsten. They focus hard X-rays that glance off those reflecting surfaces at an extremely shallow angle. To capture sufficient X-rays to ensure high-quality images, the mirror segments are nested one inside the other—a total of 133 concentric shells of mirrors for each telescope. To create the mirror segments, sheets of glass are placed atop molds, or mandrels, and heated until they “slump” to the required shape.

I have been developing and perfecting the process for forming these mirror segments for more than a decade. My coworkers and I first had to find a way to prevent the glass sheet from sticking to the mandrel surface at the slumping temperature: 600 degrees centigrade. After investigating a number of materials, we settled on a boron-nitride slurry that is widely used in industrial casting processes. The specific challenge we had to meet was to smooth the boron-nitride release layer so that it does not create a texture on the finished glass segments. Any texture or roughness on the glass surface would result in scattering that would degrade X-ray image quality.

Many trials and errors led us to a procedure that smoothed the initially rough boron-nitride surface to a mirror finish. Then we had to reengineer the interior surfaces of commercially procured electric ovens to create a clean environment, because any particulates in the oven could be trapped between the glass sheet and the mandrel surface, creating craters on the finished mirror surface and degrading image quality. Fortunately, we were able to find a ceramic slurry that, after being sprayed on the interior surface and a bake-out, dries into a smooth and clean surface, very much like glazed ceramic tiles. Finally we had to map the temperatures inside each oven to ensure they would provide a uniform heating environment so the glass sheets could slump in a controlled and gradual way. Any “wrinkles” inadvertently introduced would lead to permanent error on the finished mirror segment.

NuSTAR required a total of nearly 9,000 mirror segments: just under 3,000 for each of the two telescopes that would fly on the spacecraft plus another 3,000 for a spare. To make sure we could guarantee to provide that many, and given the inevitability of breakage and other losses during the many steps between their creation and their finally being integrated into the telescopes, we decided to produce 20,000. Of those, we shipped 15,000 to the Danish Technical University in Copenhagen and Columbia University in New York City, where they were coated with multilayers and assembled into the two telescopes.

Astrophysicist William Zhang conceived an idea for making curved or slumped glass mirror segments to focus highly energetic X-ray photons.

Photo Credit: NASA/Chris Gunn

The challenge was not only producing these delicate components to the necessary rigorous specifications but also doing so within the constraints imposed by a stringent project budget and schedule. We needed to combine the precision of custom work with the efficiency of something like industrial mass production. That meant honing the process to make each step as efficient, simple, and reliable as possible. For example, we reduced the amount of time required to smooth the boron-nitride coat from fifteen weeks to less than eight weeks. We also had to optimize the temperature cycle of the oven to reduce the overall amount of cycle time from thirty-one hours to less than sixteen hours, so the process could be completed overnight. This reduction was absolutely essential to meet the project schedule.

I knew we needed savvy, hands-on people to do the work. Practical experience with handling materials—a sense of the “feel” of things—was much more important than theoretical knowledge. Fortunately for us, a nearby automotive shop was downsizing as a result of the recession. We quickly picked up six of their technicians who fit the bill.

In February 2008, Goddard management made available to us a warehouse to use. We had to clean it and create a clean room and buy ovens and other equipment. Then our team had three months of training. The training of a new worker starts with familiarizing him or her with handling the 0.21-mm-thick glass sheets. Typically during the first two weeks on the job, a worker would break a number of mirror segments. Miraculously, workers rarely broke a mirror segment once they got the knack of handling it. The training ends with the worker being able to work independently, from operating ultrasonic cleaners to programming electronic oven controllers and cutting the thin glass mirrors with a nearly 100-percent success rate. In the spring of 2009, we began cranking out mirrors. We finished in early 2011, slightly ahead of project schedule and 10 percent under budget, saving more than $500,000 for the project.

The entire manufacturing process was not without surprises, however. In the summer of 2009, for instance, we found that some mirror segments had unacceptably high micro-roughness. We quickly traced this problem to a detergent we were using to clean the glass sheets in ultrasonic cleaners. The particular batch of detergent was exceedingly alkaline and was chemically etching the glass sheets, compromising the pristine, extremely smooth surface that is required. We quickly implemented a procedure to monitor the pH of the ultrasonic solution and the time that each glass sheet is soaked.

Continuous Improvement

Three quantities define the power of a telescope. One is angular resolution, or the ability of optics to image objects located at a small angular distance from each other as separate. Another is total photon-collecting area. The third is energy bandwidth—the range of photons of different energies a telescope can focus.

Given the budget limitations and related mass limitations of small Explorer missions like NuSTAR, the collecting area of an orbiting X-ray telescope is essentially fixed. Bandwidth is relatively fixed as well, limited by the physics of mirrors and detectors. So the one place that has significant room for improvement is angular resolution, which is largely a function of the precision of the mirrors. That’s what we’ve been working on since the completion of our work for NuSTAR.

We have made improvements in all three areas involved in making these telescopes.

Different views of one of two optic units onboard NuSTAR, each consisting of 133 nested cylindrical mirror shells as thin as a fingernail. The mirrors are arranged in this way in order to focus as much X-ray light as possible.

Photo Credit: NASA/JPL-Caltech

Substrate. We are now making the mandrels more precise. For NuSTAR, we formed two or three layers on each mandrel and distorted them slightly to fit one within the other. Now each layer has its own mandrel. More than doubling the number of molds has required us to lower the price of each by 50 percent. For a future mission we are working on reducing the cost of making mandrels so that, for the same budget as NuSTAR, we expect to be able to make two to three times the number of mandrels.

Coating. The NuSTAR substrates were coated with silicon and tungsten in alternate layers, each approximately 30 angstroms thick. That coating was somewhat “stressy” (meaning the coating exerted stress on the substrate) and therefore distorted the glass slightly when it was applied. We have now developed and optimized an annealing process that can effectively relieve all the coating stress, resulting in the preservation of the substrate figure.

Assembly. In assembling the NuSTAR mirrors, colleagues at Columbia University had to force them into shape to fit them together. Now, more precise mirror shapes and improved assembly techniques have eliminated most of the distortion that process created. In the new process we have developed, each mirror segment is attached to the housing at only a small number of discrete locations, resulting in less constraint and distortion.

Taken together, these improvements reduce distortion by a factor of ten, leading to significantly better angular resolution. NuSTAR’s telescopes have an angular resolution of 58 arc seconds. (An arc second is 1/3,600th of a degree.) We expect future telescopes to achieve an angular resolution of better than 10 arc seconds.

These new telescopes will fly first on a balloon or a sounding rocket. In the future, orbiting on a NuSTAR-like spacecraft, they will be able to see fainter objects farther away in space and further back in time, adding to our growing knowledge of the nature and origin of the universe.

Related Links

About the Author

|

William W. Zhang is an astrophysicist at Goddard Space Flight Center. In addition to his work for NuSTAR, he is leading a group of scientists and engineers developing lightweight and high-angular-resolution X-ray optics for future NASA missions. |