By Glenn A. Robinson, Jr.

I graduated in 1963 with a degree in aerospace engineering from North Carolina State University and immediately went to work at the Marshall Space Flight Center. At that time, all of us young engineers were assigned to work on smaller pieces of the Saturn V.

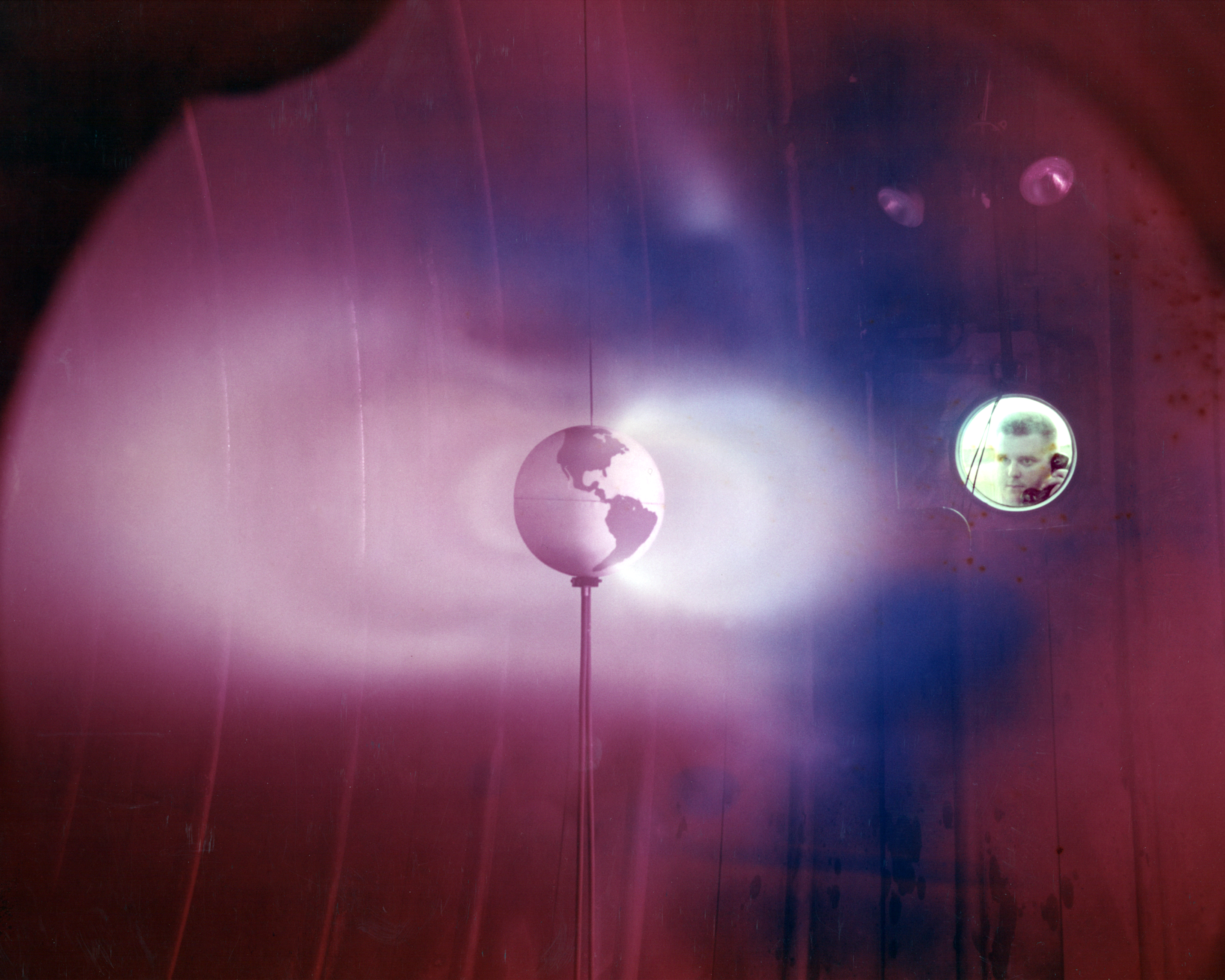

This photograph depicts a view of the test firing of all five F-1 engines for the Saturn V S-IC test stage at the Marshall Space Flight Center.

Photo Credit: NASA

As you can imagine, I was a fresh-out with no experience at all. My first week at Marshall, I was told, “We’re building this testing facility, and you’re going to be the engineer on it.” I knew nothing about building facilities, let alone aerospace test facilities. But based on that experience and similar experiences, I would strongly recommend that a young engineer who goes to work for NASA or an aerospace firm start in a test area. It teaches you that you cannot build things overnight. Materials must be ordered and delivered. Planning and initial work must be done.

Working on that test facility at Marshall, I understood some simple realities. The electricians could not do anything until we had a structure. We could not build the structure until the foundation was in place. We learned to establish realistic schedules for that up-front work. Hardware was the same. We started with an idea, defined it, and then drew it on paper (no CAD-CAM in those days). Some people may believe that such things can be built quickly, but it takes time to do everything.

Hands-On Knowledge

At Marshall in 1963, there were a number of people who were “wage-board employees.” Almost all of them were World War II veterans, most in their forties and fifties. The majority of them had no college education, but they had incredible knowledge. I don’t believe we could have accomplished what we did without them. We also had a complete machine shop in our building. If we did not have something that we needed, these veterans would go into the shop and build it. It was obvious to me how we won World War II when I watched these guys. If something was not immediately available, they’d build it from scratch.

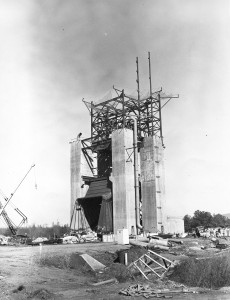

At its founding, Marshall inherited the army’s Jupiter and Redstone test stands, but much larger facilities were needed for the giant stages of the Saturn V. From 1960 to 1964, the existing stands were remodeled and a sizable new test area was developed. The new comprehensive test complex for propulsion and structural dynamics was unique within the nation and the free world, and it remains so today because it was constructed with foresight to future as well as current needs.

Photo Credit: NASA

When I first came to Marshall, I had ten wage-board employees working for me, building a Saturn V model engine test-firing stand to evaluate building a Saturn V launch platform over water. These guys had a wealth of accumulated, hands-on knowledge and common sense. When we finished building the test stand, our first test was to fire a model of the F-1 engine. These were LOX/RP1 engines (liquid oxygen and jet fuel). As part of the testing, we had to do valve timings to make sure that the propellants came in at the correct time.

While we were putting the facility together, one of the wage-board employees said to me, “Robbie, if we set these valves up like they’re telling us to set them up, I think we’re going to burn that engine up.”

I asked, “Why?”

He said, “Well, they’ve got us coming in with an oxidizer lead.”

I said, “Well, the guys who configured it are supposed to know what they’re doing.” Of course, I was an inexperienced, twenty-one-year-old kid; I didn’t really know what I was doing. But I decided to discuss his concern with some of the senior engineers. They concluded that it was not a problem. I went back and told the technicians.

They said, “Don’t worry about it. After we melt the first one, we’ll fix it.”

Sure enough, in the first test firing we burned up an injector. So I went back to the technician and said, “Henry [Henry Hilton was his name], how did you know that this was going to happen? I have an aerospace engineering degree, but we never studied anything like this at NC State.”

Henry answered, “It’s very simple. I looked at it like an acetylene torch.”

“What do you mean?” I asked.

Henry said, “An acetylene torch will do one of two things. You can either solder with it—melt stuff to put it together—or you can cut with it. If you’re running oxidizer rich, guess what: you cut with it.” He explained that all we had done was to create an acetylene torch, which caused a meltdown of the injector. I was a relative youngster with an engineering degree, but since I could admit that I didn’t know everything and was willing to ask questions, I gained the respect of the team working with me. I continued to benefit from their knowledge over the next few years as we worked together testing different parts of the Saturn rockets.

In those early days of human space flight, NASA built and assembled a lot of the flight and test hardware, then built the facilities for all the experimental testing we did. Much of the Saturn hardware was designed at Marshall. Today, most of it is designed and built by contractor teams at their facilities. It’s a very different environment. I believe that part of the problem that exists at NASA today is that the old and experienced engineers (including me) move up into management and no longer have the opportunity to do much technical work with the young employees who are coming aboard. These new, young engineers work with other young engineers. I consider it to be a shame that we, who have had the experiences and the knowledge gained from many failures and successes, have not gotten more technically involved with our younger, less-experienced employees.

Working for Von Braun

Wernher von Braun was a fascinating individual. If he met you once he would remember your name. Over the years, I had opportunities to fly on the Gulf Stream with him. The director’s seat was always at the back. People would get to the Redstone airfield early so they could sit near von Braun. He was fun and exciting to be around. He could talk on almost any subject; he was extremely knowledgeable. It didn’t matter whether you were a fresh-out twenty-one-year-old engineer or someone who had been around for twenty years; he was always willing have discussions with you. He was very open-minded, listened to what people had to say, and considered their recommendations. But once he made a decision, the decision was made and the decision was his.

Von Braun would come down to the test stand that I was running as a very young test engineer and ask my permission to go out on the stand. His attitude was, “This is your environment, and you’re in charge.” Away from the test stand, there was no question: he was the center director, and he was in charge.

The 138-foot-long first stage of the Saturn V is lowered to the ground following a successful static test firing at Marshall Space Flight Center’s S-1C test stand.

Photo Credit: NASA

We did much of the S1B testing at Marshall. Back then, we didn’t have the computers that we rely on today. We used consoles with switches to manually operate all the valves and strip charts with ink pens to record measurements and data. A number of us were asked to support one of the S1B firings by monitoring some of the redlines. As I recall, the chamber pressure for the H-1 engine was 1,000 psig and the redline was slightly above that.

Those of us watching critical redlines were given cut-off switches. About two minutes into the test, the needle touched the redline on the chamber pressure of the engine I was monitoring and then went slightly above. I punched my button and shut down the test. Of course, it became really quiet in the room. Everyone was looking around to see who had shut it down. I admitted being the “culprit.” An investigation followed. The more senior people asked, “Why did you shut it down?”

Needless to say, I acknowledged that I had shut down the test because the chamber pressure exceeded the redline by a couple of psi. The senior engineers asked, “Couldn’t you see it was stable and it wasn’t going anywhere?” They were going on and on like that, as typical engineers do. Von Braun had been sitting in the back during this “inquisition.”

After a few minutes of intense inquiry he spoke up and asked, “What did you tell my young engineer to do?”

They answered, “We told him to shut it down if it hit the redline.”

Von Braun asked, “Did it hit the redline?”

“Well, yes, it exceeded the redline by a couple of psi.”

Von Braun responded, “Well, the young engineer did what you told him to do. Quit criticizing him. Change your redlines if they’re wrong and leave my young engineers alone.” Only he said it with a little bit more explicit language. That ended that, and, no, the redlines were never changed.

The Apollo Spirit

During that exciting time, money was not an issue like it is today. Our only challenges were technical. We all worked six or seven days a week to accomplish our mission of landing a man on the moon within the decade. We were very close, committed to our work and to each other. It is very difficult to describe the camaraderie. We played softball together; we worked together; we went fishing together; we vacationed together. Our environment was very much like being on a college football team. Our coaches were von Braun and the management team at Marshall. I believe that the only problem we had then was that we took greater risks than we should have. For example, we lost a couple of guys on a tank that blew up. They had been leak-checking the tank while it was pressurized at a level that was too high. We had a few other accidents along the road to our successes. Nobody heard much about those events. Our environment said, “We’re going to do this.” We were all gung ho. I don’t think there was anything that we thought we couldn’t do. Our accomplishments are a national legacy. Our spirit is part of the legacy, too, but it came with a silent price.