By Ken Atkins

In the wee hours of Sunday morning, January 15, 2006, a 105-lb. entry vehicle carrying samples of dust from comet Wild 2 and interstellar particles from outside our solar system whizzed into our atmosphere at 29,000 mph.

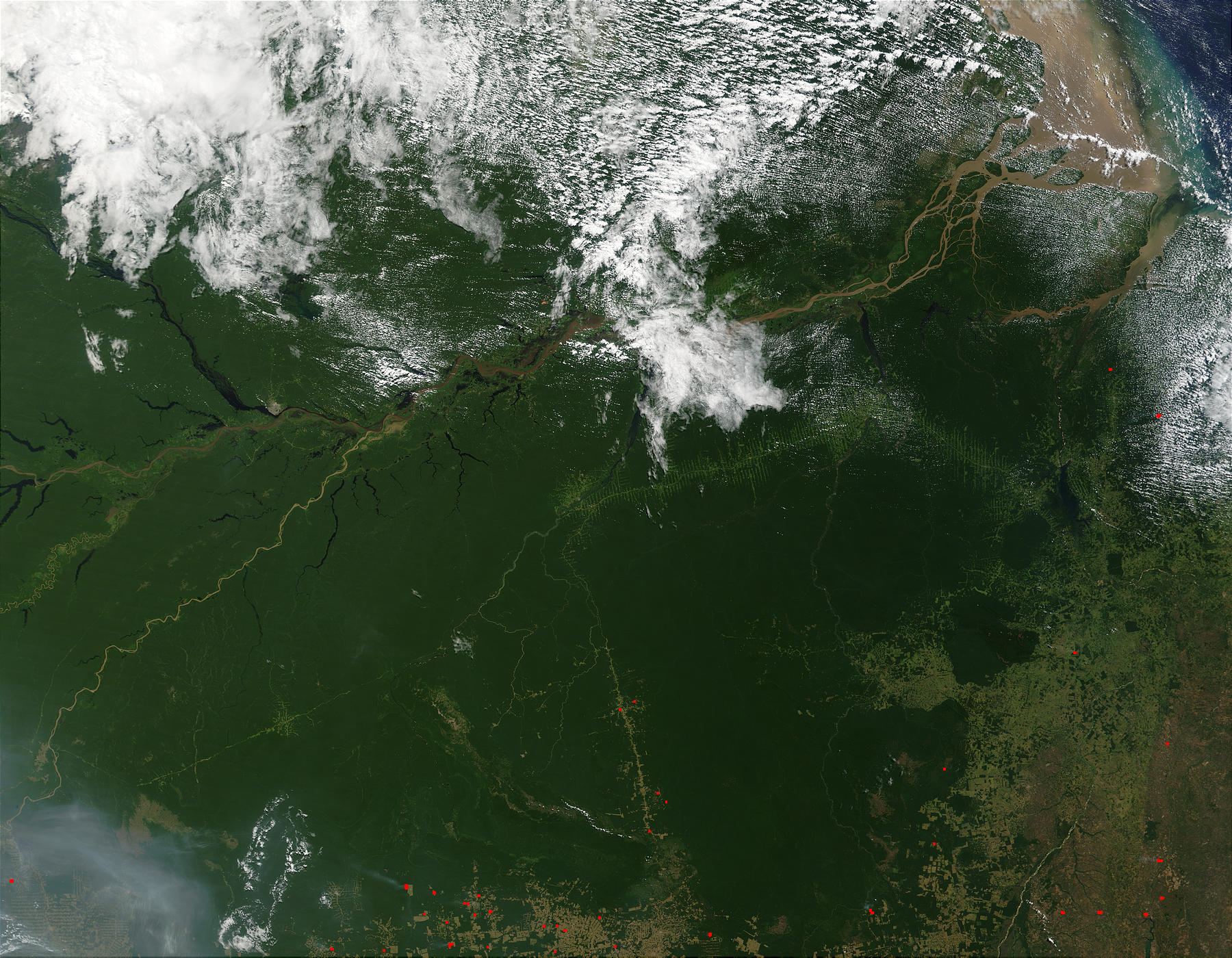

Stardust Capsule Return as seen from NASA’s DC-8 Airborne Laboratory with a mission to explore the conditions during re-entry from the light emitted by the fireball caused when the capsule streaked through the sky. The aircraft was located near the end of the trajectory, just outside the Utah Test and Training Range.

Photo by NASA / Ames Research Center

It had been on a seven-year, three-billion-mile odyssey around our solar system and, on the way, had punched through the comet’s dust cloud at about 13,000 mph, just 149 miles above the jagged surface, its tennis-racket-sized Aerogel array collecting dust from the particle stream. This carrier- capsule combo had flown halfway to Jupiter, more than 250,000,000 miles from the sun, with electrical systems powered only by sunlight. Over the course from Earth to comet and back, Stardust performed thirty-seven thrusting maneuvers for calibrations and trajectory corrections.

Of course, there had been problems on the way. Fault protection software placed the spacecraft into “safe mode” ten times and nearly forty-two software patches were transmitted and installed to handle needed repairs and upgrades. The most spectacular safing occurred when a massive solar flare hit the spacecraft on November 8, 2000, “confusing” the star cameras and causing the computers to reboot five times in approximately six minutes, eventually taking the ship all the way to terminal safe mode. However, the machine was performing as planned, and the flight team patiently waited until the storm passed and then commanded a recovery to full flight capability, still on course for its January 15, 2006, delivery. The parachute-deployment failure Genesis suffered led us to reconfirm that Stardust’s deployment system had been adequately tested and did not share the Genesis design flaw. Even so, the team planned and trained for unlikely but possible return and recovery contingencies.

Sources of Success

Looking back across ten years, this long, technically and organizationally challenging project had succeeded brilliantly. I attribute its success to the unifying power of an inspiring goal, an effective results-driven organizing structure, and clear and open communication.

Stardust’s inspiring goal unified the team and helped even the grumpiest of us get beyond disagreements instead of letting technical issues, schedule, or cost—those three horses of project apocalypse—get out of control. Members shared a commitment to control all three to achieve the goal everyone relished explaining to friends, families, and anyone who would listen. Pursuit of that goal made people selfless. Engineers worked hard in their own subsystems to conserve reserves for others. Principal Investigator Don Brownlee was a master at conveying his enthusiasm for getting at comets, those ghosts of the solar system. I’d known Don and many of his colleagues from my early days at Jet Propulsion Laboratory (JPL), when we worked together to try and get a U.S. mission to fly to comet Halley. He was an excellent “missionary” for this adventure. With an engineering degree supplementing his scientific résumé, he understood what engineers could and could not do. Together we became cheerleaders for our team.

In large measure, I credit the NASA Discovery Program Manager, Mark Saunders, and his selection criteria for Discovery 4 with creating the foundation for a results-driven action structure that didn’t force me to be the budget bad guy (and force others to hide bad news). In fact, I was able to release reserves to preemptively counter threats and risk. Looking for ways to attack risk before it attacked us, we spent about a million dollars on risk-reduction before launch. Nothing earns trust like being able to go to the people in the trenches and say, “How about if we add some money to your cost account so you have a higher probability of making those milestones at high quality?” A host of team players orchestrated the action structure to get the job done with focus and efficiency. In development, Rick Grammier, our Project Engineer (who moved on after launch to manage Deep Impact) led a strong systems-oriented group to document all our processes, sweep for risks, and get our flight system produced, tested, and delivered to a successful launch in February 1999.

None of this would have happened without effective communication. Clear communication translates to a high- performing team. It is true that knowledge is power, but only if that knowledge is fully shared.

The Stardust sample return capsule was transported by helicopter from its landing site at the U.S. Air Force Utah Test and Training Range. This image shows the return capsule inside a protective covering.

Photo by NASA

Openness builds a culture of trust and counters the “us versus them” attitude organizations trying to work together often fall prey to. In addition to providing an accurate measure of where we stood, our performance management system and earned-value metrics shed “sunlight” on facts. Rick’s team used an innovative virtual meeting structure, engineered by JPL’s Lori Carr and her information technology counterparts at Lockheed Martin Space Systems (LMSS), that included the phone network (including the just emerging, but still “iffy” cellular phone), collaborative servers for near-real-time data access, pagers to summon folks to the network, and secretaries and administrative people who could, as a last resort, quickly track them down to ensure communications were timely and decisions were made and logged without delay. I remember attendees calling into the meetings using seat-back phones on commercial airliners, presentations being made from phone booths, and timely technical answers provided by cellular phone from a car en route to LMSS’s Denver plant. The language was goal-directed, not ego-driven or rules-driven. Everybody wanted to know what was happening. Data were open and available. And “What do you think?” was a common inclusive query to keep everyone contributing. I relied on General Bill Creech’s insight, in The Five Pillars of TQM, that a key communication ingredient is listening. He says, “Listen for the echoes to learn if it’s all getting through.”

The Moment of Truth

The Stardust team was flooded with emotion Saturday evening, January 14, 2006, as we realized that the final flight chapter of our ten-year effort was about to begin. I was confident in our team and their work, but there are always unknowns. No vehicle had ever entered the atmosphere as fast as the Stardust sample return capsule. It had a new (in 1997) high-technology heat shield. The chute system had never been operationally used, since Genesis’s did not deploy. The recovery team might have a challenge in finding the small capsule if the beacon on the chute risers didn’t work or if weather kept the helicopters from flying.

At four hours before atmosphere entry, Stardust successfully “dropped” the sample return capsule right on schedule and, fifteen minutes later, maneuvered to avoid following it into the atmospheric cauldron. My successor, Tom Duxbury, Flight Phase Project Manager, and his Flight and Recovery Team at LMSS, JPL, and the Utah Test and Training Range had done a superb job of flying the spacecraft the Development Team turned over to them almost seven years ago.

Everything went our way: weather clearing so the helicopters could fly, entry at 400,000 feet and 29,000 mph, pick-up by the radars, excellent navigation predictions on touchdown point and time. Then the moment of truth when the small drogue chute was to deploy at mach 1.4 and 105,000 feet. Bingo! Exactly on time, the small, white blip on the infrared tracking jumped upward off the screen. The drogue had deployed to stabilize the capsule through the transonic zone and prevent tumbling. The tracking camera reacquired the white blip of the capsule, and it glowed steadily, without the blinking that would indicate tumbling. Everyone erupted in joy as drogue deployment was confirmed.

Then, standing in anticipation, we waited for the 10,000- foot mark where the main chute would deploy as the drogue was jettisoned. We were euphoric as the call came confirming we were on the main chute, and we could see the ghostly black-and-white image of the 27-foot canopy’s reflectors and the tiny sample return capsule swinging below. It was floating down almost exactly as depicted in the pre-launch animation film I’d shown a thousand times in presentations I’d given. The pick-up helicopters locked on to the beacon. Touchdown was at nine mph and two minutes early, only four miles northeast of the target landing point due to wind drift. My feelings? Indescribable joy: gratitude for the first-class engineering team from Lockheed-Martin Astronautics that produced and flew the spacecraft and Boeing’s tried-and- true Delta II team that blasted us off the Earth February 7, 1999; awe at the skills of the JPL navigators, the operators of the deep- space tracking network, and the recovery team of the Air Force and LMSS in Utah; and giddiness that Don Brownlee and his science team—and eventually teams from all over the world— would indeed get their hands on primeval material unchanged over 4.5 billion years.

There had been many moments in Stardust’s ten years when the abyss seemed to open and design issues, scope pressures, test failures, parts, cash flow, contract issues, personal conflicts, unknowns, and loss of signal threatened to end the project. But commitment to the goal, trust, communication, and a results- driven action structure gave us a robust ship that sailed the sea of space, captured the treasure, and returned home to tell the tale.

“More Kudos”

Tom Duxbury, the Mission Design and Engineering Manager who took over as Project Manager during the Flight Phase with Ed Hirst and Bob Ryan of JPL, and Joe Vellinga, Allan Cheuvront, and Mike McGee from LMSS put together a Flight and Recovery Team that did a brilliant job of piloting Stardust through three billion miles of adventure to a perfect touchdown. Tom and his team became masters of patience as they flew Stardust through tense times when its signal “disappeared.” However, the ship always “called home,” and they ultimately trusted that the spacecraft would perform exactly as planned.

Joe Vellinga, our LMSS manager for development and flight, ensured that the flight system met “design-to-cost, test as you fly, fly as you test” goals. With Rick Wanner, our LMSS Assembly, Test, and Launch Ops Manager, Joe fostered the open and selfless engineering that built trust between LMSS and the team at JPL.

Finally, the Project Control Team ensured discipline through the performance management system with a fast, honest collection of earned-value data. They quickly turned data into metrics on receivables, deliverables, events completed, and, most importantly, reserves on cost-to-go. Bredt Martin, Ralph Bartera, and Walt Boyd of JPL teamed with Rick Price, Brian Overman, and their LMSS EV specialists in an open file-sharing approach to earned-value management (EVM) that had enough discipline to be timely and to maintain baseline and data integrity without the unnecessary restrictions typical of a tri-service-validated system. Operationally, all significant variances were investigated by the team and then addressed by the cost-account owners as necessary to explain variations. This tailored approach to EVM made it a legitimate tool to keep the apocalyptic horses in harness. We got a valuable, trustworthy indicator of performance against the baseline plan. While EVM is not applicable to flight phase activity, the cultural discipline from the development phase transferred to Duxbury and Vellinga’s Flight Team with excellent results. Stardust achieved a solid reputation for meeting its technical, cost, and schedule commitments.