By Dustin Gohmert

As Orion seat subsystem manager, I had been working with contractor Lockheed Martin for approximately a year and a half on the design of an astronaut seat for the new crew exploration vehicle, Orion. The seat would have to protect astronauts from the “high landing loads,” or g-forces, of landings on water or land, including those where problems like one of the parachutes not opening or high crosswinds would expose the crew to higher-than-expected loads. Even a perfect landing is what you might call a “controlled crash.”

We knew that an effective seat would be one that spread those forces evenly over the astronaut’s body and constrained motion to avoid the harm done to limbs or head flung in any direction. Given the tight quarters of the six-person capsule and payload considerations, the seats would have to be compact, lightweight, and easily storable when not in use. We decided early on that the solution the Russians used on Soyuz—custom seats molded to every astronaut—would not work for us. Among other things, they could not be folded for storage and would create problems when astronauts took shifts on the International Space Station (and would presumably have to keep their seats with them).

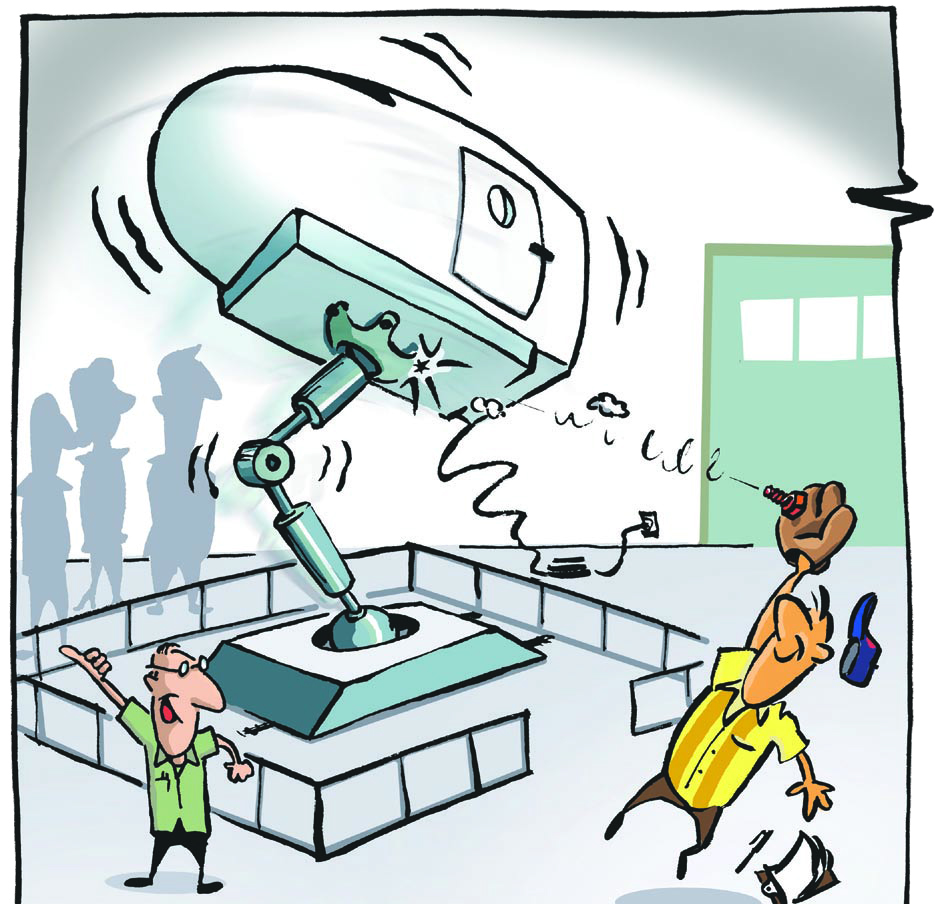

The Advanced Crew Escape Suit (ACES) fit in the Orion concept seat is evaluated. ACES was used as the reference suit for the anthropometric guidance provided for seat design.

Photo courtesy Dustin Gohmert

By December 2007, Lockheed Martin had a seat that was set to meet the myriad requirements specified early in the project. While this seat was a good overall solution, NASA faced a dilemma: it was built to requirements specified before the team fully understood the extent of potential landing injury problems and how to solve them. That often happens when you’re designing something new: you discover things in the process of doing the work that you needed to know to define the requirements, but couldn’t have known at the time the requirements had to be written.

Since that time we had learned a lot, especially from the technologies auto racing had developed to protect drivers. Years of experience and experiment had gone into seats designed for NASCAR, Indy, and Monster Truck racing. Monster Truck drivers repeatedly experience forces as great as 18 G’s— comparable to some of the worst impacts the astronauts could experience. NASCAR and Indy racers routinely survive impacts of greater than 50 G’s with little or no injury. The veteran racing designers shared their knowledge with us freely and enthusiastically. We also got valuable information from Apollo astronauts and vehicle design teams. Solutions used on Apollo were shared by the folks who have done this work before us; for instance, they used heel clips to help immobilize the astronauts’ legs during reentry and landing. That helped provide a solution to our potential leg-flail concerns.

So we had a much better idea now of what the seat needed to do and how we might give it those capabilities, but the Lockheed Martin and NASA seat team already had a viable design that fulfilled the requirements laid out in black and white. To upgrade the requirements and rewrite contractual agreements could delay us several months in the critical time approaching our design reviews.

Do Try This at Home

As people discussed the seat during team meetings on impact safety, I found myself thinking, “that’s a good idea,” or, “that probably won’t work.” Those judgments reflected what we were learning together and also my own earlier work on the orange pressure suits the shuttle crew wear during launch and reentry. Those suits are the “interface” between the astronaut and the chair, so understanding how they are constructed was essential to understanding the seat. One problem with the existing design, clearly, was that the seat was flat and people are not. And we hadn’t fully solved the problem of adjusting for different leg lengths to provide continuous support. I began to have a good sense of what the seat should look like. As I’ve mentioned, though, we were not at a point where we could stop work and start over from scratch.

I decided I would try to come up with something at home over the Christmas–New Year’s holiday that might help put us on the right track, thinking that if I came up with a design that worked, NASA might support it and Lockheed Martin might be able to take it to the next level without further contract negotiations.

There were some other reasons the idea appealed to me. I liked hands-on work; I grew up on a ranch in Texas where you needed to know how to fix things and build them from scratch. And I’d recently gotten some new tools that I wanted to try out. So I walked up and down the aisles of the local Home Depot, thinking, “I’ll probably need this.” I spent $200, which I hoped I’d eventually get reimbursed for.

The Advanced Crew Escape Suit (ACES) fit in the Orion concept seat is evaluated. ACES was used as the reference suit for the anthropometric guidance provided for seat design.

Photo courtesy Dustin Gohmert

The first thing I did was ask my fiancée to draw the outline of my body on big sheets of cardboard. That gave me a template I could use to shape the chair, designing, most importantly, a curved, adjustable lower part of the seat that matched the curve of the buttocks. Of course we had done computer modeling to try to fit body shapes to chair designs, but computer models tend to be too rigid when designing for the ultimate non-rigid interface: the human body. One model, for instance, showed that the fit between suit and seat would be too tight when in actual fact it left space that needed to be filled. I worked ten ten- to twelve-hour days in my garage. (At 10:30 p.m. on New Year’s Eve, my fiancée said, “So, are we going out?” We did.) At the end of that time, I had a full-size working prototype made out of wood, metal, and fabric. Its main new features were the adjustable, curved lower section and spacers of various sizes that could make a snug fit between the seat and astronauts’ shoulders and hips.

Why Build a Prototype?

There were good reasons for building a prototype rather than just sketching my ideas. For one thing, you learn by touching the hardware. It teaches you that sometimes what looks good on paper is impossible to make—every piece of hardware is a compromise between an idea and the realities of physical materials. Also, the hardware shows you things you couldn’t guess from diagrams. When I tested my prototype with people of very different heights and leg and arm lengths, I was surprised to find that everyone’s hands always ended up near their knees. That gave me the idea of putting the controllers near the knees on the sides of the flight crews’ chairs, thereby eliminating the complication of separate armrests for the hand controllers.

The other reason for building a prototype is that I knew that sketches can easily be dismissed for lack of clarity or understanding (or can lead to long discussions about whether or not the design would work in the real world). Everybody has sketches, but not everybody has a full-size working prototype. In other words, the squeaky wheel gets the attention, and I squeaked as loud as I could. Because I knew the impression the prototype made would be important, I spent time sanding edges and painting the wooden parts to make it look as professional as possible.

Back to Teamwork

After the holidays, I took the prototype and a PowerPoint presentation I had created “on the road” to numerous boards and meetings of groups overseeing the project and to my Lockheed Martin colleagues. I didn’t present the seat design as my brilliant idea, because it wasn’t. It was a product of a lot of learning that the whole team had done and of contributions from many sources: the Lockheed Martin design team, race-car engineers, suit designers, former astronauts, and others. Building the seat was really an exercise in integration, not an exercise in invention. I specifically designed the new seat features as an upgrade to the already existing good design, not as a replacement for it. That made it easier to foster team commitment to the changes without significant impact or rework on the sound foundation that had already been laid.

From there the teamwork continued. For instance, I had struggled to find a good way to have the leg and foot support slide in for storage; I never found a satisfactory answer. The Lockheed Martin guys quickly saw that it would be easier and better to have that part of the seat fold over. It was an obvious solution, but I hadn’t seen it. I also worried that a bar at the end of the footrest would stick up when the seat was in the stored position. I stopped worrying when an astronaut looked at it and liked the bar that way, saying, “I can tuck my toes under here on orbit.”

Lockheed Martin fairly quickly built an improved metal version of the prototype seat, while incorporating new creative solutions in the design. As I write this, it is scheduled for impactsled testing with crash-test dummies at Wright-Patterson. I’m sure we will learn things that influence the final design of the seat, but we seem to be on the right track. I’m proud of the contribution I made by spending those ten days incorporating what we had learned into a prototype, but this has truly been a team effort and will continue as one for years to come as we work to provide the safest seats ever ridden to space and back.

About the Author

| Dustin Gohmert is the seat subsystem manager at Johnson Space Center for NASA’s new crew exploration vehicle, Orion. |