By Jennifer Cole

Our team was working with the Department of Homeland Security (DHS) on one of those rare projects that is just big enough. In other words, we had just enough experts on board to be effective yet flexible. I was the youngest as the chief engineer. Although I’d been chief engineer on a project or two before, this was my first time working directly with another government agency. I was relatively new to working with my NASA team, which included seven engineers and pilots. Our team was diverse in terms of experience, skills, and personalities, but we had one thing in common: we really enjoyed the task at hand.

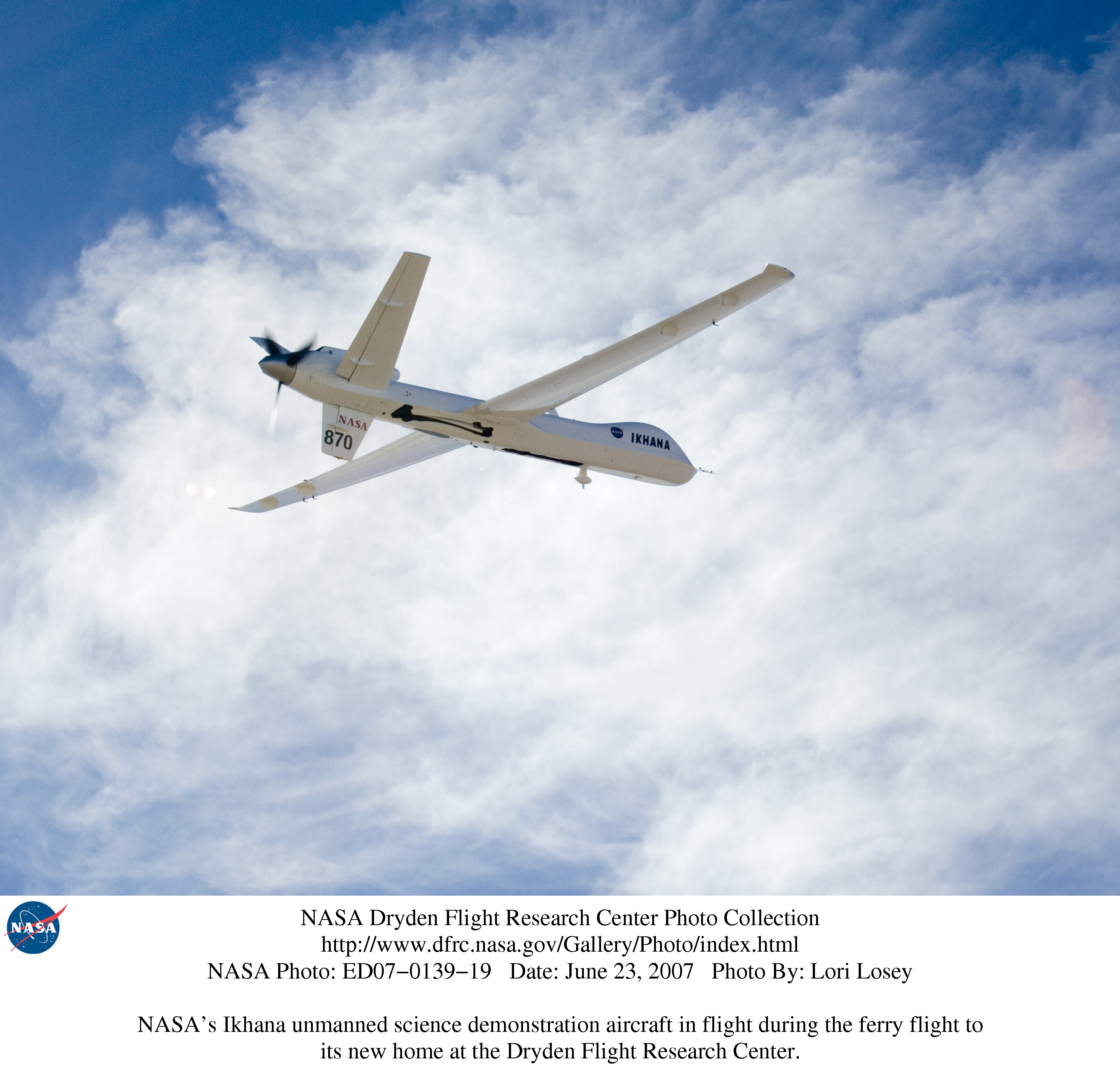

That task consisted of figuring out how to safely control and land an airliner using just the thrust from the engines. This is called throttles-only control (TOC). We weren’t allowed to modify the airliner in any way, given the time and cost involved, and we had to use a “stock” airliner with line pilots. The idea was to give the pilots an emergency checklist that would provide them with the most useful information in the shortest time to learn how to fly TOC. Homeland Security was interested in expertise Dryden Flight Research Center gained from the earlier propulsion-controlled aircraft (PCA) project, which demonstrated the feasibility of the idea with an automatic MD-11 landing using just engine thrust for all axes of control. Although that project employed extensive modifications to the aircraft and engines, the concept of throttles-only control was researched extensively, in both airplanes and simulations.

Dryden didn’t have in-house simulations of the airliner, and our test pilots are probably far from being representative of line pilots. So DHS made arrangements with an airline to get access to their simulations and their pilots and carry out a test flight with their airplanes. We research engineers are used to working with simulations rife with every parameter imaginable, delivered in a standard format and at a specified data rate. An airline simulation, however, is used for pilot training and certification. Our first challenge was to set up a conversation with the airline’s simulation engineer to identify the common ground between the limitations of the training simulation and our engineering needs. The simulation data was going to form the foundation of our flights, so the quality, format, and type of data were of critical importance.

Initially, this presented a challenge from both sides as we tried to make a training simulation into an engineering simulation. We struck common ground when we were finally face to face and could explain what we needed and what the airline could provide without significant modifications. As we worked together, the simulation engineer suggested improvements that helped us out a lot. By the way, that conversation continued until the very last day of our work, as our parameter list evolved and the last data set was produced. It is clear now that this open, solid communication link with our simulation engineer was a critical aspect of the project’s success; it enabled us to get the best and most consistent data set possible.

Next was scheduling time in the simulation. Because of their intended use, airline simulations are tightly scheduled in multihour blocks around the clock. Although the airline was getting paid for our time in the simulation, we didn’t exactly outrank the captains, who got the prime spots. We usually had the 6:00 a.m.–10:00 a.m. slot, but once or twice we got bumped to the

10:00 p.m.–2:00 a.m. slot. I felt especially bad for our simulation engineer, who remained essentially “on call” during our simulation times in case we crashed it (as one might crash a computer), couldn’t reset it, or realized we’d left a parameter or two out of our required list. We strove to maintain a good working relationship with him by giving him as much lead time as possible to make modifications. In the beginning, both entities set clear expectations, which helped establish a good working foundation. Throughout the project, we treated his support of our work in the simulation with top priority.

We had a limited number of simulation hours, and a limited amount of travel money, so we meticulously planned every last minute of those simulation visits, which took us one time zone and three states away from California.

We were in the zone, so to speak, getting great data. We had one flight under our belt and had established an excellent working relationship with both Homeland Security and the airline. We kept all our customers in the loop on our progress, and we didn’t sugarcoat it. When we had a concern, we made sure to communicate it in the context of how it would affect the final product, and we communicated it to the appropriate level and with a workable solution, if we had one.

As with any engineering endeavor, our team had to make certain simplifying assumptions to stay within the scope of the task. As we progressed further into the research, we kept a running list of our unknowns and key assumptions. Some time after the first flight, we had identified plenty of areas for further research. Together, we organized and prioritized several key areas that we felt warranted further study, from validating our simplifying assumptions to exploring the checklist’s application to other airframes, and presented our ideas to DHS. Because we already had the group identified and working together, it made sense to build the foundation necessary to explore these other areas now to simplify our efforts later, if DHS wanted to fund further work. Then we ran into a big brick wall.

The DHS program office that was supporting us had its funding redirected due to new priorities. Almost overnight, our current work and certainly our future work were in jeopardy. Our small group took this rather hard as there is nothing worse than pouring your heart and soul (and weekends!) into a project and then getting the rug yanked out from under you. Although we had all experienced this before in our aerospace careers, this one stung especially hard, perhaps because we were such a small, flexible group and were giving the customer exactly what they wanted. Although we weren’t cheap, we were conducting research effectively and efficiently, the way all projects intend. As the technical experts, we were given the authority to make technical decisions, even big ones. If we had a question about project scope or aircraft capability, we had the phone number of the person who could answer it.

As the chief engineer, I served largely as “management” when we were on travel, so I learned firsthand about problems and successes. Now, it was incumbent upon me to keep us moving toward our goal, doing as much as we could for as long as we could, without getting mired in the muck of why this had to happen and also searching for a reason we understood.

First things first: we refocused on the task at hand. There was a possibility that we wouldn’t get a second flight, which meant that we had to reprioritize our simulation times. We had to strike a balance between pilot availability and simulation time; if pilots weren’t available at the same time as the simulation, we had a prioritized list of research maneuvers to do instead with the rest of the research team. When the pilots were there, we focused more on refining the checklist. Either way, we functioned as a well-oiled machine, quickly moving from one maneuver to the next. Every person in the simulation (and for the flights) had a specific role, from pilot to flight test engineer to qualitative data recording.

Once the team had its sights set on what we could still do, we stopped wasting energy on the things we couldn’t control. We communicated our tweaked “replan” back to DHS and the airline to make sure our priorities still aligned. We kept the conversation focused on the minimum level of support we needed to still deliver a product and what that product would look like. All the players were in the room, and everyone had a stake, operating just as we had since the beginning. Ultimately, we were able to get everyone’s concurrence, and DHS gave us the approval to proceed.

We headed back to the simulations. It was difficult to get remotivated, sitting in the simulation before the sun was even up and gearing up for another four hours in close quarters. Our jokes turned sarcastic, and we had some exhausted faces at dinners. Generally speaking, I am a rather happy person who always tries to look on the bright side of things, but even I was really disappointed.

Rather than try and be the lone ray of sunshine, I concentrated on keeping our group on schedule. We still had breakfast at the cafeteria every morning before our sessions and lunch afterward. We still had dinners in the local restaurants, we still met for coffee in the hotel lobby, and we always met during our long afternoons to discuss what we’d learned that day and how it affected the next day’s work. This helped to keep the group together as we moved forward.

Remember the diverse set of personalities mentioned earlier? The potpourri of people on this project really helped to keep us going and smiling. One member of the group seemed particularly susceptible to adventures during travel, from getting upgraded to first class because of purported center-of-gravity issues to taking off before the rest of the group and somehow landing after us. His stories provided much needed humor and a sense of anticipation as we all wondered what the story was going to be this time. Another engineer had to be talked into joining us for our simulation sessions. I pseudo-bribed him into going with us by loaning him seasons from my collection of The SimpsonsDVDs. This became a running joke, as we ran out of simulation sessions before I ran out of Simpsons episodes. We learned that pilots enjoy eating almost as much as they enjoy flying, and our simulation engineer became known as God, as only he could bring us back from a failed maneuver or save our data.

It was the little things—the oatmeal breakfast before the simulation session and the turkey sandwiches and apple pie afterward, the complimentary hotel coffee, the Simpsons jokes, and the vortex of activity that always followed one particular team member—that kept us going during the tough times. We finished our simulation sessions, received permission to do our final flight, obtained one-of-a-kind data, and finished the year with our final report to Homeland Security. Two years later, we are still fielding requests for presentations and the occasional interview, and our team’s collective efforts have been recognized with a NASA Group Achievement Award.

About the Author

| Jennifer Cole is chief of the Research Aerodynamics and Propulsion Branch at Dryden Flight Research Center in Edwards, California. |