By Piers Bizony

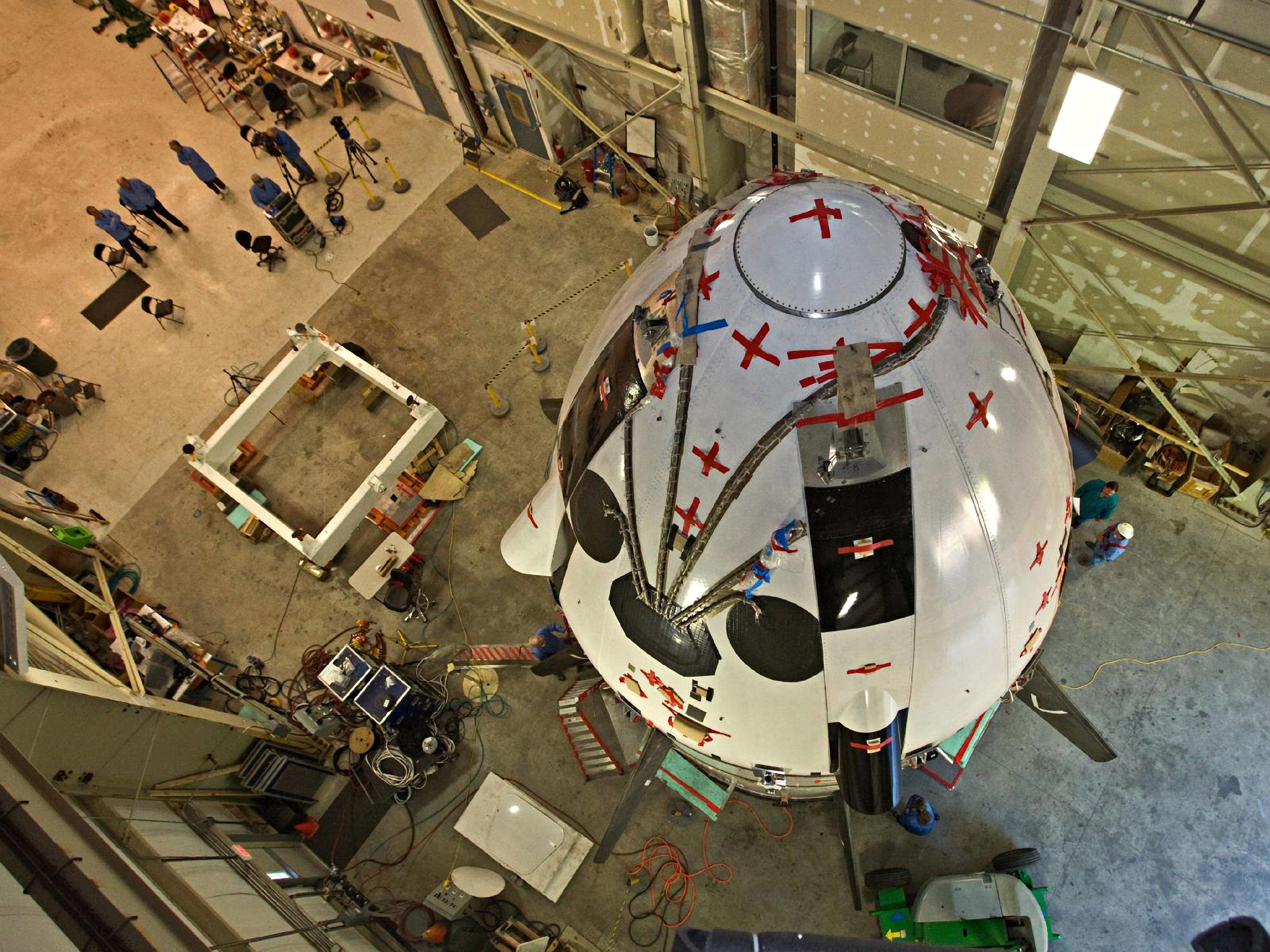

In April 2007, a team of awestruck technicians discovered that the apparently lifeless artifacts on display from a long-vanished era of space exploration were not quite so dead after all. They carefully removed access panels on an old spaceship, revealing pristine mechanisms within.

The Apollo command modules on display at Kennedy Space Center’s Saturn V Complex. The umbilical housing compartment can be seen between the service and crew modules in the lower-right area of the image.

Photo Credit: NASA Kennedy Space Center

The Apollo spacecraft on display at the Kennedy Space Center in Florida is the unflown backup for the 1975 Apollo–Soyuz docking mission that signaled the end of the Cold War space rivalry. All its systems are intact. Dan Catalano and a privileged group of mechanical engineers and pyrotechnics experts from Glenn Research Center in Ohio were granted permission to strip down the one small section of this spacecraft that most interested them. They wanted the answer to a problem that continues to challenge the best minds in modern space engineering.

At the end of its mission, and just prior to reentry into Earth’s atmosphere, an Apollo capsule had to separate cleanly from the rear service module that had carried most of its air, water, electrical supplies, and propulsion fuels. Dozens of power wires, fluid cables, and data conduits had to be disconnected in an instant. How was this reliably accomplished?

Behind the umbilical housing sat a tiny set of explosive guillotines, through which all the cables and lines snaked in a neat bundle. When the time came for the capsule to drop away, the guillotines sliced through metal and plastic as though they were butter. A backup set of guillotines, powered by an entirely separate electrical system, insured against failure. And all this was in a box the size of a car battery. Forty years later, Apollo still has lessons to teach as NASA gears up for a return to deep-space astronaut missions using capsules.

Catalano said, “I grew up in the Apollo age and used to watch all the launches. I was a product of that era. To be able to come and actually touch the hardware is a real thrill for me.” Convincing the general public, thronging past this and similar museum exhibits, to be equally impressed is a challenge. There is something about the superficial appearance of the old Apollo equipment that needs to be explained to them.

In popular culture, spaceships are supposed to look sleek and futuristic but, even today, the real-life hardware sometimes lacks a certain stylishness. There is a reason for this. Take a look, for instance, at how commercial airliners are built. The production runs are large enough to justify the initial huge costs of purpose-built factory tooling and templates. The cabins have molded interior fittings that tuck neatly into the corners and meet seamlessly with the window frames, the foldaway tables look like they belong on the back of the seats, and so on. There will be some decorative flourish, probably featuring the airline logo. Inside and out, everything fits together into a more or less cohesive whole.

The same cannot be said of a typical spacecraft. These are hand-built machines, with populist styling absolutely not on anyone’s priority list. It makes no economic sense for aerospace companies or space agencies to create production lines for machinery that is only going to be assembled a few times. And, given the energy required to lift mass into orbit, spacecraft designers do not have the luxury of adding merely decorative touches. Consequently, there is a spare, nuts-and-bolts feel to most spacecraft that causes inexperienced observers to think of them as disappointingly crude, almost willfully antique.

The cultural reference point for what spaceships are supposed to look like is almost certainly Stanley Kubrick’s 1968 science-fiction film 2001: A Space Odyssey, itself a product of the age of Apollo. Kubrick’s prop designers first sat down at their drawing tables in 1964, at the start of what would turn out to be a long and complex production, yet the ships they invented still look futuristic and still tend to dominate everyone’s thinking when it comes to the “archetypes” for space machinery.

Kubrick took advice from the corporate world, and they in turn delivered idealized versions of what they expected space vehicles to look like. Crucially, they envisaged a world in which the commercial marketing of space transportation was commonplace. Hence, each cabin and cockpit in 2001 had a sleek look designed to appeal as much to the paying customers in the passenger seats as to the pilots who flew up front.

It is fascinating that the new space tourism companies, such as Virgin Galactic, have thought along similar lines, creating interiors for their suborbital spacecraft that satisfy our expectations of how things should be, with digital control panels, soft padding on the cabin walls, and space meals you can suck through a straw, just like in 2001. This is all an illusion, a marketing ploy. In real life, the interiors of space shuttles or Apollo capsules do not look at all luxurious.

Visitors to space museums expect gleaming science-fiction props, and the real spacecraft that they encounter often leave them slightly shocked. They peer through the hatch of an Apollo capsule and see a dimly lit interior encrusted with ancient clockwork. There are no touch-sensitive screens or plasma displays. The instrument panels are a mechanical maze of switches and dials, and the electrical energies that once powered them no longer lend them some energy.

People are struck by how primitive everything looks. In particular they often observe that the lunar module seems, today, like something lashed together by kids in preschool. The styling of technology changes, and people’s expectations have evolved with it. If we want to gain an impression of how futuristic Apollo seemed four decades ago, we need to make a couple of time-travel journeys of the imagination.

First, picture Louis Blériot in 1909 making what seemed at the time an epic journey, a crossing of the English Channel by air, in a monoplane of such fragile design it seems unthinkable, today, that anyone could have trusted their life to it. Look also at Charles Lindbergh’s Spirit of St. Louis. Would you expect that machine, with its homemade finish, to have carried a man safely across the Atlantic Ocean? Yet these two famous planes were heralded as portents of a new world. They were futuristic, because no one had seen anything like them at that time.

To the generation who witnessed Apollo when its hardware was factory fresh, the vehicles conveyed a similarly novel and futuristic impression. Picture the command module brand new, covered in mirror-smooth silver-foil insulation so that it looked like a single piece of polished metal. (The foil burns off during reentry, leaving the capsule a drab, brown color.) Now visualize the interior of the spacecraft surgically clean and brightly lit so that the astronauts can see what they are doing. There is not a single scuff, nor the tiniest flaw, in the paintwork. The fans and air-conditioning units are humming, and the control panel is a shimmer of lights and trembling dials. Apollo seems almost alive. By the standards of the 1960s at least, this was the most advanced machine in history—and everyone who saw it at the time sensed that truth.

The same applied to Apollo’s electronics. We often hear that the onboard Apollo Guidance Computer (AGC) had less power than a modern digital watch. But it all depends on what we mean by “power.” At the time, it was one of the most capable computers ever invented.

With the umbilical housing cover safely detached, the intact cord assembly is in full view.

Photo Credit: NASA Kennedy Space Center

In terms of raw processing capability, our modern home PCs may be more “powerful” than an AGC, but they tend to be plugged into just a few interfaces with the outside world: a printer, a backup disc drive, a screen, and a router. By contrast, an AGC was connected to a three-axis inertial navigation system allied to an optical star telescope, while its twin aboard the lunar module also absorbed data from two radar rangefinders: one directed toward the lunar surface, the other keeping tabs on the orbiting command module. The AGC also mediated between the astronauts and the thrusters and rocket engines that drove their ships through space.

Translating the AGC’s capacity into modern computing parlance can be misleading, but its magnetic core ROM stored the entire suite of guidance programs in the equivalent of about 36 kilobytes. Here lies another of the extraordinary “powers” that this machine possessed: the power of lines of software reduced to their most disciplined fundamentals, so that a small amount of code could deliver astonishing results.

The AGC’s third and most important “power” was a reliability that we can only dream of today. Nothing was “stored” in ROM when the AGC was switched off, but once activated, it booted up in less than a second. It was a totally hardwired system, because the software was encoded as patterns of wiring, snaking in and out of the little ring-shaped cores, that could not be overwritten or erased. Even when Apollo 12 was struck by lightning soon after launch in November 1969, and the interior of the capsule blacked out for a moment, its AGC swiftly recovered to fly the rest of the mission. It was a reliable piece of equipment because it had to be. Lives depended on it.

The AGC’s fourth “power” was the ability to change the broader world around it. The computer processor itself depended on a relatively untried device: the integrated circuit. The first examples had been invented as recently as 1958 by Jack Kilby of Texas Instruments. A year later, Robert Noyce of Fairchild Semiconductors (and later, the founder of Intel) refined the process by putting all the components on a silicon chip and connecting them with copper lines.

It’s a cliché that Apollo kick-started the microchip revolution, but there’s some truth here. NASA bought up 60 percent of America’s entire output of integrated circuits in the early 1960s, deliberately allowing the new industry to acclimate itself to mass production and reliability checking of new chips, and temporarily shoring up an industry for which few other markets yet existed.

Another revolution was in the means by which people with little desire to become computer experts (the astronauts) could communicate with the AGC via a small display and keyboard, known as DSKY. They inputted short numeric codes, signifying programs that they wished to initiate. The DSKY then “talked” back at them with five lines of numeric displays and a small panel of sixteen labeled lights.

DSKY transformed the relationship between people and computers. With our touch-sensitive screens and graphic interfaces, we take for granted our ability to operate computers without having to understand their internal workings. In the early 1960s, the idea of nonspecialists having anything to do with them was radical.

The AGC was the mediator of another new union, commonplace today but revolutionary at the time: that between computers and airplanes. On May 25, 1972, test pilot Gary Krier flew a modified F-8 Crusader jet fighter, knowing that for the first time in history, his joystick commands did not feed directly to the aircraft’s flight control surfaces but were first verified and adjusted by an electronic mind. Sixty percent of the software for the world’s first-ever fly-by-wire aircraft consisted purely of Apollo code. This success changed the future course of aviation.

The history of AGC and the many other Apollo innovations also informs our future. As NASA reaches for new horizons in space, it is essential that it pioneer new and inspirational technologies whose influences ripple throughout the culture and economy at large, just as the machines of Apollo did forty years ago. Bold innovation continues to be a key responsibility for NASA. When those involved with the current generation of space architecture next engage with the public, we must hope and expect that they can give as good an account of the technological revolutions they are creating as the designers of Apollo could.