By Steve Glover

NASA’s Space Shuttle is one of the most complex systems ever designed, manufactured, and operated. The shuttle program is organizationally complex, too. The program elements that keep it flying are located in many NASA centers, with prime contractors and supporting suppliers spread across the United States. Many of the industries supporting the shuttle, though mainly located in the United States, have parts of their operations in other countries. Coordinating the work of these many organizations requires a major integration effort. The complexity of the shuttle and its support structure adds to the challenge of tracking and responding to environmentally driven reformulation and obsolescence of some of the several thousand products the program uses.

Generally speaking, environmental regulations have evolved from an early 1980s focus on establishing compliance requirements and cleaning up contaminated sites to pollution prevention, risk, source control, green engineering, and sustainability. This change includes an industry trend toward reducing the use and production of many chemicals with the potential to harm humans or the environment. The resulting numerous material and product changes, reformulations, and closeouts raise issues for NASA as well as for the Department of Defense, other federal agencies, and private industry.

The effects of these changes are of special concern to human spaceflight programs, which require highly reliable systems. Environmental regulations and environmentally driven industrial trends can lead to a host of consequences, including risks to safety, schedule, cost, performance, and reliability. One chemical change can potentially involve numerous flight hardware materials. Finding adequate replacements may involve extensive testing and qualification efforts.

The thermal protection system used on the external tank offers one example of continuing environmental challenges. The system contains foam materials that insulate the liquid hydrogen and liquid oxygen propellants inside the tank, maintaining them at their cryogenic temperatures and preventing ice formation on the tank exterior. A chemical blowing agent provides the critical insulation and cell-structure properties of these foams. The foam blowing agent used early in the shuttle program was chlorofluorocarbon (CFC)-11, a class I ozone-depleting chemical. It was phased out of production at the end of 1995 by Environmental Protection Agency regulations.

Considerable research and development were required to qualify a replacement agent: hydrochlorofluorocarbon (HCFC)-141b, a class II blowing agent with lower ozone-depleting potential. When, in 2003, regulations also phased this material out of production, the shuttle program and NASA Environmental Management Division worked with the Environmental Protection Agency to obtain an allowance to continue production of this flight-critical material until the end of the program. The orbiters and solid rocket boosters also used this foam, but the orbiter project team has been able to replace HCFC-141b with an insulating material that is free of ozone-depleting chemicals.

The Environmental Challenge

Identifying and mitigating environmentally driven risk is a large, complex, challenging task. Obsolescence risks stem from both regulatory influences and industrial trends. Regulations for a particular chemical may include detailed requirements affecting production, uses, discharges, and emissions. Some chemicals are placed on watch lists as agencies evaluate their potential health and environmental effects. Some are regulated outside the United States, and chemicals may be regulated at the federal, state, and local level. To further complicate matters, regulations are subject to continual updates and changes.

Industrial changes may occur for a number of reasons. Companies may decide to eliminate or reduce the use of certain chemicals based on their regulatory status, their known or potential toxicity, or the likelihood of future regulation. Our concerns about these changes fall into two categories: unidentified changes and material performance changes. Not knowing when a company changes a formulation is of course a major concern.

Space Shuttle project elements work with their vendors to identify changes before they occur, but suppliers to those vendors sometimes change their products without notice. It is important to have controls in place to flag unexpected product changes. Often only limited information is available about the influence of regulatory requirements on industry. When changes occur, understanding how the new material will perform is essential. We must understand specific uses, processes, and controls involving any changing material so we can appropriately assess the risks. Key questions to ask include, what is the use of a particular chemical or material? Is it a critical use? How many places is it used? Once we are aware of a material change, we must coordinate with the supplier to understand the change and review the supplier acceptance testing as well as our in-house testing. If that testing is inadequate to determine performance, we need to develop and carry out new qualification testing and/or technical analysis to verify that the material will perform to the specifications.

The Shuttle Environmental Assurance Team

In the late 1990s, some members of the materials technical community realized they needed to work together to try to solve problems created by the continuing impact of product obsolescence on the shuttle program. This early informal team, called the Shuttle Replacement Technology Team, began identifying potential environmentally driven obsolescence issues and shared data and approaches to mitigating those risks. In 2000, the Space Shuttle program manager directed that a formal Shuttle Environmental Assurance (SEA) initiative be established to put a team and processes in place to proactively identify, communicate, and mitigate environmental assurance risks. The team would communicate with both management and the technical community.

The team is a multidisciplinary, multifunctional group made up of representatives from the shuttle program, project elements (orbiter, Space Shuttle main engine, reusable solid rocket boosters, external tank, flight crew equipment, ground support equipment), associated prime contractors, and members from supporting organizations, including NASA Headquarters, the Space Operations Mission Directorate, the Environmental Management Division, NASA centers, International Space Station program, Constellation program, and the U.S. Air Force.

Our first task in developing the SEA team was to create a group that covered all shuttle project elements, the prime contractors, the centers (mainly environmental offices and materials engineering offices), NASA Headquarters, and other supporting organizations that focus on shuttle operations. We successfully recruited team members who have the information, knowledge, and skills to identify, communicate, and help each other mitigate issues. Once the team was established, we had to answer questions concerning our scope and processes, and how to reach our overall environmental assurance objectives. Also, determining how we would create requirements and hold such a large team responsible without explicit authority (since we depend on some organizations outside the shuttle program) was a major task. Several individuals from earlier groups helped us define requirements that made good sense for all stakeholders. Dealing with environmentally driven issues often requires the expertise and cooperation of many stakeholders.

Establishing effective communication has been a major team accomplishment, but it has not come easily. Obtaining information from stakeholders and understanding their different perspectives, integrating risks across shuttle elements, getting centers to talk to each other, connecting centers and programs and environmental engineering to materials engineering, and communicating to the program and project community on environmental issues have been major challenges. The sheer volume of regulatory reviews and the amount of information we need to communicate was initially overwhelming.

We have developed good communication channels that include the SEA Web site, technical interchange face-to-face meetings, and regular teleconferences. Our documentation and reporting provide clear, concise information about risks and concerns. In addition, we developed a regulatory matrix to help communicate regulatory changes and identify potential risks. We also use technical notices to communicate industry changes. Facilitated risk analysis has been an important tool, since we often work with multiple risks that have to be integrated into programmatic risk. We also use technical papers to collect the factual information on a potential issue so the risk can be evaluated appropriately. We have established interfaces with other government agencies to share information on risk and mitigations.

Broad Benefits

The work we do has a direct impact on the success of shuttle missions. We have been successful in mitigating environmentally driven risks because we provide sound technical work and risk mitigation, create products the community finds useful, and save cost and time. Our team approach has saved resources by sharing technical information, coordinating mitigation work, and using common risk, technical, and communication tools. Many SEA products and processes benefit programs other than the shuttle. For instance, the experience gained by the Space Shuttle program in understanding regulatory requirements and trying to find a replacement for HCFC-141b is helping the Constellation program in its replacement and allowance efforts.

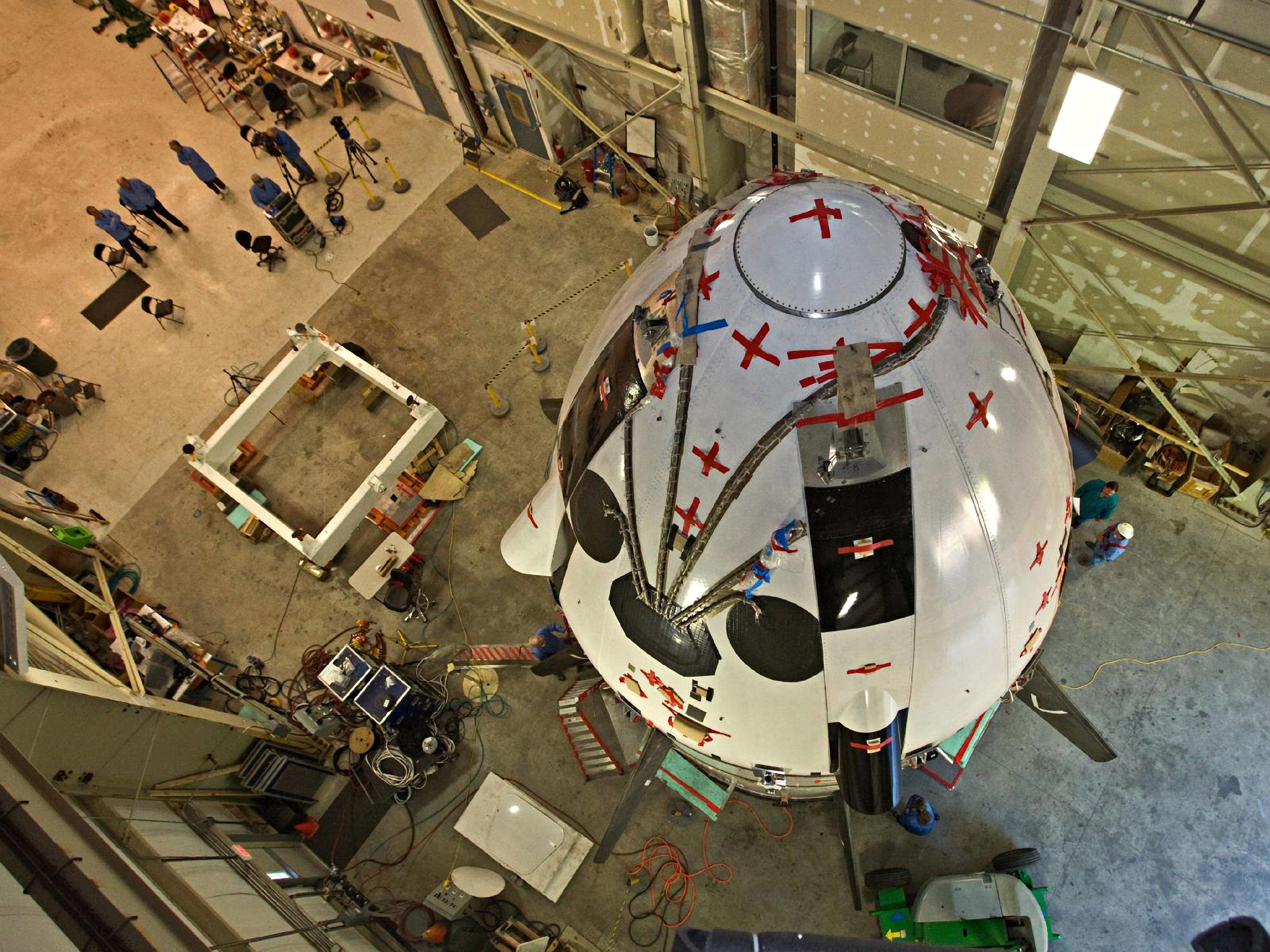

Handheld still image taken by Discovery’s crew of the external fuel tank as it was jettisoned after launch of STS-114.

Photo Credit: NASA

The SEA team has formalized access to technical experts in materials engineering, logistics, and environmental requirements. The SEA team gives NASA a technical connection to data and reviews on proposed environmental legislation and regulations, executive orders, and Environmental Protection Agency research that could affect NASA missions. Our risk management process and reporting process also help connect working scientists and engineers to the higher-level managers.

Other NASA programs face or will face environmental issues similar to the shuttle’s, so it has made sense to include the International Space Station program and the Constellation program in SEA activities. Continuing government and industry efforts to protect the environment will affect virtually all NASA programs. The SEA team will continue to help deal effectively with the issues those actions will create for the duration of the shuttle program. Working as part of this very professional and dedicated SEA team to meet these challenges has been a very gratifying experience.