By Mike Menzel

The James Webb Space Telescope (JWST), scheduled for launch in 2018, is expected to show us the most distant galaxies that formed in the early life of the universe. To do this, it has light-gathering capability unprecedented in a space telescopeits 6.5-meter-diameter mirror has more than six times the light-collecting area of Hubble’s mirror. Also, it is designed to “see” mainly infrared radiation so it can detect the red-shifted radiation of early stars and make out stars and planets that are hidden from visible-light telescopes by clouds of gas and dust.

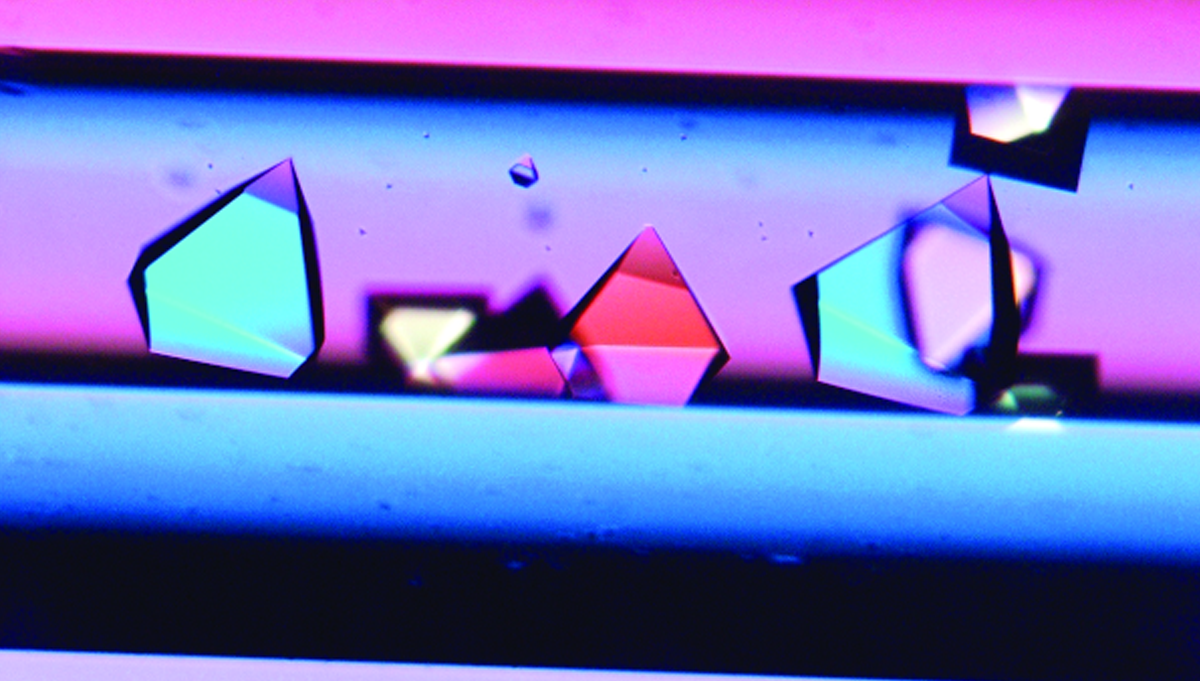

Technicians at Marshall Space Flight Center completed a series of cryogenic tests on six James Webb Space Telescope beryllium mirror segments at the center’s X-ray and Cryogenic Facility. The mirrors were subjected to extreme temperatures dipping to -415ºF, permitting engineers to measure in extreme detail how the shape of the mirror changes as it cools.

Photo Credit: NASA

Because infrared is essentially heat, JWST’s telescope and instruments must be extremely cold so those faint signals from distant objects will not be overwhelmed by the “noise” generated by the heat of the telescope and instruments themselves. To maintain the required low temperature—around 40 K or approximately -233°C—JWST will be located in deep space, about a million miles from Earth, with a sophisticated system of shields and radiators to cool down the hardware to prevent solar radiation from heating the telescope and instruments.

The challenge to JWST’s thermal design group has been to design and test the hardware that will keep the instruments of this very large observatory at a very low temperature despite being in an environment where it will constantly be bombarded with 200,000 watts of solar energy—and to provide enough design margin to be certain the thermal design will work. With JWST a million miles away, a Hubble-style repair mission is out of the question. If the thermal design fails, so will the mission.

This task can be accomplished without radically new technical innovation. The basic principles of the sunshields and radiators have been used before. But the extremes of the temperature requirements and the constraints imposed by mass and budget limitations have made this a daunting task.

Previous cryogenic space hardware had masses of not more than about 500 kg; JWST needs to cool over 3,700 kg. Not only did we have to make sure that no more than 1 watt of the 200,000 watts of solar energy would get through JWST’s heat shield, we had to fully understand the paths that 1-watt seepage would take to “sneak” around from the hot side to the cold side of the observatory, tracking down to tens of milliwatts to determine where to place the thermal shields and radiators that would disperse most of that residual energy.

The extreme vigilance required is hard to describe. We went into extraordinary detail in analysis and design, not wanting to overestimate the thermal insulation needs of JWST (and spend more mass and budget than necessary), but guarding against unjustified optimism that would increase the risk of underperformance.

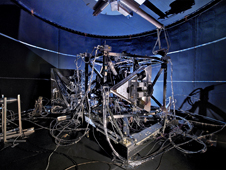

Dan McGregor, lead venting analyst at Northrop Grumman, places a sunshield test article in the vacuum chamber at Aerospace Systems’ test facility in Redondo Beach, Calif.

Photo Credit: Northrop Grumman Aerospace Systems

Experience and Cooperation

The prior experience of team leaders Keith Parrish and Shaun Thomson from Goddard Space Flight Center and Perry Knollenberg from Northrop Grumman was essential to ensuring a robust thermal system. Through their past experience, they understood the risks and challenges of designing a passively cooled cryogenic system. People who have done cryogenic work before—even if less demanding work than JWST requires—have a feel for how much margin is needed and how much difference a seemingly tiny variation in temperature can make. Newcomers to the field are likely to underestimate both. These team leads understood the critical cryogenic demands and reminded the team to “concentrate on detailed heat-flow diagrams and follow the milliwatts.”

Members of the JWST team also had prior large-telescope experience from working on the Hubble, Chandra, or Spitzer telescopes. Part of the Hubble experience—being a member of a “badgeless” system team where contractors and civil servants worked side by side, not concerned about which organization signed their paycheck—proved essential to the JWST work.

While updating the observatory thermal-integrated models with results from engineering and component tests soon after JWST’s critical design review in April 2010, the team determined that interface characteristics between components was not adequately represented in the models. Many of the problems found in the detailed heat-flow map did not lend themselves to be cleanly allocated to discrete-element product teams because they resided in the interfaces between these elements and had to be addressed at an overall system level. In other words, they could only be solved by a badgeless team concerned not with ownership of the individual elements but with responsibility for the system as a whole.

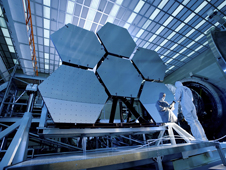

The telescope’s integrated science instrument module in the helium shroud, where it underwent cryogenic testing. The NIRSpec mass simulator is attached to its left side.

Photo Credit: NASA Goddard Space Flight Center/Chris Gunn

That meant bringing together people from a variety of organizations. The JWST program is an international collaboration with Goddard as the mission lead and contributions coming from the European and Canadian space agencies. In addition, Goddard holds contracts with Northrop Grumman as the observatory contractor, with Ball Aerospace as telescope subcontractor, and with the University of Arizona. An effective systems team required participation from all these teams without parochial interests getting in the way.

That multiplicity of players and the typical separations caused by the way money and work orders flow in the organizations meant that we had to avoid the dangers of so-called “stovepiping”—groups carrying out their assigned tasks more or less isolated from one another. The telltale signs of stovepiping are groups saying, “Just tell us our requirements and let us design the element,” or, “Leave us alone to provide an optimized product.” But the sum of optimized elements rarely adds up to an optimized system.

A stovepiped organization can obstruct solutions that involve give and take among elements to optimize systems performance as a whole—the kind of teamwork we needed for the thermal design. Stovepipes also can obscure problems, either because a subgroup’s decision to solve a problem on its own keeps it hidden from the larger team or because the people who could recognize a problem are not party to essential “global” information. Finally, stovepipes hinder a program’s ability to form cross-organizational teams that draw on the people best able to address problems regardless of where they are located.

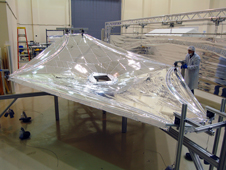

A one-third-scale model of the sunshield was built for testing and refining the team’s understanding of thermal issues. Here, one layer of the model undergoes tension testing at the Nexolve facility.

Photo Credit: Nexolve

To get rid of stovepipes and their negative effects, we were able to consolidate systems engineering for JWST under a common Goddard-led team. For many members of the team, this was an unfamiliar way of working, but in the case of the thermal systems team, the transition was extremely smooth. This was due in part to the urgency of solving the thermal problems and in part to the professionalism of the thermal leadership and the thermal team as a whole. We got the skills we needed to solve our thermal-engineering problems by creating a unified thermal-engineering group of people from Goddard, Northrop Grumman, our science teams, and the product teams (optical telescope element, integrated science-instrument module, and sunshield). Members of the group were not co-located, but they traveled a great deal and met almost daily during periods of the most intense work.

Working closely with the science communities that will use the observatory was also essential to getting the design right. We needed to understand the sensitivity of mission science objectives to subtleties of observatory performance. Some science instruments are inherently more sensitive to the noise of higher detector temperatures. Working with the scientists, the thermal team made what may appear to be minor tweaks to the design but which resulted in higher margins for the instruments that needed it the most.

We worked hard to keep international teams and scientists informed of progress and problems during a weekly teleconference. (We also held science group briefings every three months.) That communication and the team’s focus on the health of the program as a whole has led to important cooperation. One example is our getting scientists to agree on that proposal to keep the margins high on JWST’s most-sensitive instruments by lowering the margin a bit on the less-sensitive ones. In part, this agreement was facilitated by giving scientists time to analyze the issue. In larger part, it built on the connection and trust that already existed.

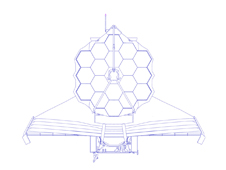

Line drawing of the James Webb Space Telescope.

Image Credit: Northrop Grumman Corporation

Testing, Learning, Fixing

To ensure our understanding of the thermal issues, we built a one-third-scale model of the sunshield and a full-scale model of the observatory’s core area (the complex transitional region between the warm and cryogenic portions of the observatory). As we tested those models and refined our understanding of the thermal issues, we discovered more and more potential threats to our thermal goals, reducing margins to levels we could not accept.

Since March 2011, our Return to Green (RTG) thermal-recovery effort employed our best cryogenic experts to “follow the milliwatts” in an exhaustive effort to identify thermal threats and develop a strategy that gives us the margins we need without burdening the system with unneeded and costly protection. It would be hard to overstate the subtleties of the work. For instance, we had to make sure that our radiators have the best possible view to the cold of space. A 40-K radiator that “sees” a 100-K heat shield would have to be larger than one that has no obstructions to deep space to shed the heat it absorbed from that “warm” shield. The team conducted some of the most detailed thermal analyses ever performed for any spacecraft, keeping careful account not only of these view factors, but also of the way in which the absorptive and emissive properties of these radiators and their environments varied with the wavelength of thermal radiation.

At the conclusion of the RTG thermal-recovery effort, the team produced a revised thermal architecture that not only restored the appropriate margins after addressing all the known risks, but also gained a 27-kg mass savings.

Thermal design is an absolutely critical element of JWST. It is one of many systems that must work together flawlessly. Outstanding teamwork, extensive expertise, and commitment to implement practices that eliminate institutional barriers that could hide risks are instrumental in ensuring that they will.

Related Links

- James Webb Space Telescope (JWST) Mission Site

- Additional JWST Images

- Behind the Webb Video Podcast

- JWST Twitter

- JWST Facebook

- JWST YouTube

About the Author

|

Mike Menzel is the NASA mission systems engineer for the James Webb Space Telescope at Goddard Space Flight Center, a position he has held since he joined NASA in June 2004. |